Page 10

For Pump technical questions, please call 1-888-866-5797.

For Engine technical questions, please call 1-800-520-0882.

ITEM 69747

SAFETY

O

PERA

TION

M

AINTENANCE

SETUP

Operation

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual

including all text under subheadings therein before set up or use of this product.

Pre-Start Checks

Inspect engine and equipment looking for damaged, loose, and missing parts before set up

and starting. If any problems are found, do not use equipment until fixed properly.

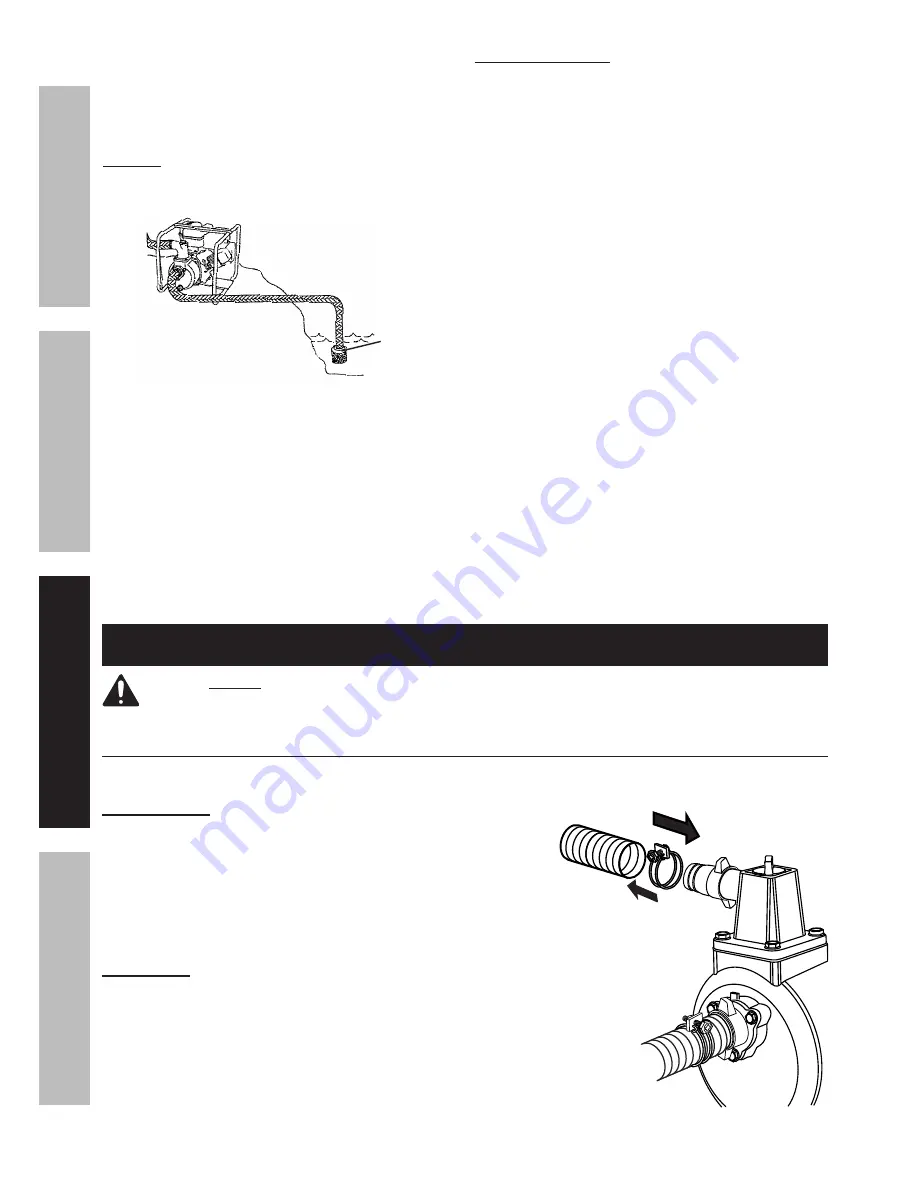

Prime the Pump

Before starting the engine, fill the Pump with water.

To do this:

1. Unthread the Priming Water Filler Cap

by turning it counterclockwise.

2. Fill the unit with clean water up to the

top of the opening. Replace the Priming

Water Filler Cap and tighten securely.

IMPORTANT!

Always check for water in the Pump

Housing before each use. Never attempt to run the

Water Pump without the Pump Housing FULL of water.

Running the Water Pump without water for

an extended period of time will damage the

Water Pump and void the Warranty.

a

b

3. Place Strainer into water to be pumped.

NOTICE:

Strainer must be fully immersed in water.

Do not operate Pump without Strainer connected

to end of suction hose. Keep Strainer out of sand

or silt by placing Strainer in a bucket or on stones.

NOTICE:

If there is an air leak in the suction line,

you may not be able to prime the pump.

Use of a thread sealant is recommended.

Strainer

4. Secure the Intake Hose in place to keep it

from moving once the Pump is turned on.

The Intake Hose should be as short as

possible for more efficient operation.

5. Route the discharge hose to the desired discharge

location. If necessary, connect additional discharge

hoses to direct the discharge to the desired location.

Make sure to secure the discharge hose in place

to keep it from moving once the Water Pump is

turned on. The discharge hose should be kept as

short as possible for more efficient operation.

Operation Concerns

1. Cavitation: This is the sudden formation and

collapse of low-pressure vapor (bubbles)

across the vanes of the impeller.

Cause: When the surface pressure on a liquid

becomes low enough, the liquid will begin to boil

(even at room temperature). With centrifugal

pumps, cavitation can occur when the suction

vacuum becomes too great, allowing water vapor

or bubbles to form at the impeller. The rapid

pressure increase can cause impeller damage.

Solution: Minimizing suction head and using

the largest practical suction hose diameter will

reduce the likelihood of cavitation.

Do not use

a suction hose with a diameter smaller than

the Pump’s Intake Port (1

"

diameter).

2. Water Hammer Pressure: This is energy

sent back to the Pump due to sudden

stoppage of water flowing from the Pump.

Cause: Water hammer pressure is more likely to

occur when using a very long discharge hose. If the

flow of water at the end of the discharge hose is shut

off suddenly, energy is sent back to the pump. This

causes a large pressure spike in the Pump housing,

leading to potential damage to the Pump casing.

Solution: Use as short a discharge

hose as possible and

turn off water

pump before closing water flow.

Summary of Contents for 69747

Page 1: ......