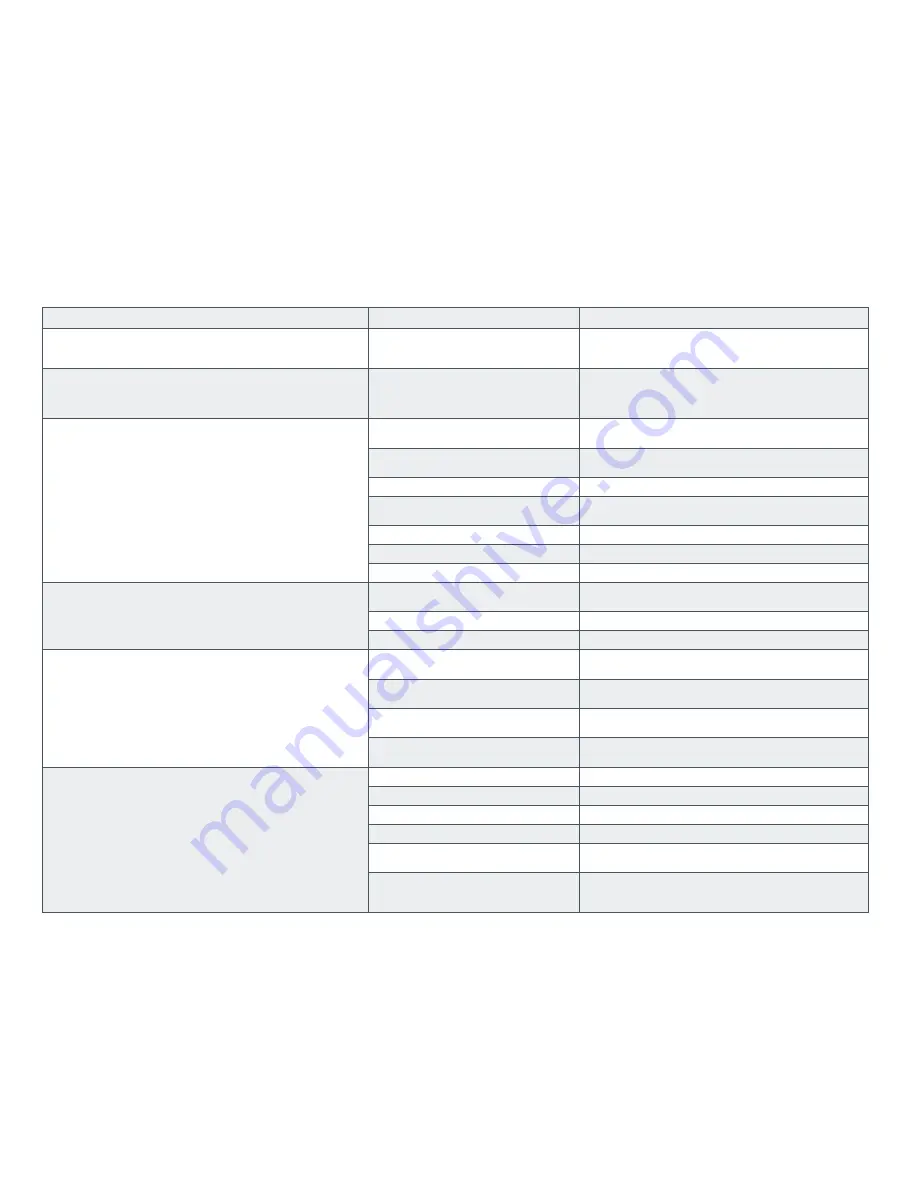

TROUBLESHOOTING GUIDE

ISSUE

POTENTIAL CAUSE

PROPOSED SOLUTION

Machine isn’t cleaning satisfactorily

Pad or brush may be worn

Inspect & replace if necessary. Brushes should be

replaced when the bristles reach a length of 3/4 in

(19 mm)

Excessive foam is being produced in the recovery tank

Detergent used is not a low foaming

detergent

Check bottle label. Use low foaming detergent or

add a small quantity of defoamer to the recovery

tank. More foam is generated when a floor is lightly

soiled. Use less detergent if this is the case

Brush motor will not activate

Scrub head is still in the transport/

storage position

Lower scrub head to operating position

Batteries are discharged to the point

that the brush motor is shut down

Recharge the batteries

Brush motor or wiring may be faulty

Contact a service center for testing

Brush motor circuit breaker has been

tripped

Reset brush motor circuit breaker on back panel of

scrubber

Brush motor relay may be faulty

Contact a service center for testing

Scrub head switch may be faulty

Contact a service center for testing

Handle switch may be faulty

Contact a service center for testing

Vacuum motor will not turn on

Squeegee is still in transport/storage

position

Lower squeegee to operating position

Vacuum motor relay may be faulty

Contact a service center for testing

Vacuum motor or wiring may be faulty

Contact a service center for testing

Traction drive (if equipped) does not activate

Traction drive motor circuit breaker

has been tripped

Reset traction drive motor circuit breaker on back

panel of scrubber

Speed control knob is turned too far

to the left

Rotate knob to the right

Traction drive motor or wiring may be

faulty

Contact a service center for testing

Traction drive motor controller may

be faulty

Contact a service center for testing

Run time is short

Batteries are discharged

Recharge the batteries for a full cycle

Wet batteries may need to be watered

See End of Shift Maintenance segment of manual

Batteries are defective

Replace batteries

Battery charger is defective

Repair or replace charger

Scrub head is locked in high down

pressure setting

Change scrub head setting from high down pressure

setting to normal operation setting

Charger is set to incorrect battery

type

Verify dip switch setting is correct on charger

using Setting the Dip Switches segment in the

Machine Preparation segment of this manual

Summary of Contents for S-20

Page 37: ...37 S 20 AUTO SCRUBBER FRAME ASSEMBLY TRACTION...

Page 38: ...38 S 20 AUTO SCRUBBER FRAME ASSEMBLY PAD BRUSH ASSIST...

Page 39: ...39 S 20 AUTO SCRUBBER SOLUTION TANK ASSEMBLY...

Page 40: ...34 S 20 AUTO SCRUBBER BATTERY ASSEMBLY...

Page 41: ...41 S 20 AUTO SCRUBBER RECOVERY TANK ASSEMBLY...

Page 42: ...42 S 20 AUTO SCRUBBER SQUEEGEE ASSEMBLY...

Page 43: ...43 S 20 AUTO SCRUBBER SQUEEGEE LINK ASSEMBLY...

Page 44: ...44 S 20 AUTO SCRUBBER HEAD LIFT ASSEMBLY DISK...

Page 45: ...45 S 20 AUTO SCRUBBER HEAD LIFT ASSEMBLY ORBITAL...

Page 46: ...46 S 20 AUTO SCRUBBER HEAD ASSEMBLY DISK...

Page 47: ...47 S 20 AUTO SCRUBBER HEAD ASSEMBLY ORBITAL...

Page 48: ...48 S 20 AUTO SCRUBBER DRIVE PLATE ASSEMBLY ORBITAL...

Page 49: ...49 S 20 AUTO SCRUBBER CONTROLS ASSEMBLY TRACTION...

Page 50: ...50 S 20 AUTO SCRUBBER CONTROLS ASSEMBLY PAD BRUSH ASSIST...

Page 51: ...51 S 20 AUTO SCRUBBER ELECTRONICS ASSEMBLY TRACTION...

Page 52: ...52 S 20 AUTO SCRUBBER ELECTRONICS ASSEMBLY PAD BRUSH ASSIST...

Page 53: ...53 S 20 AUTO SCRUBBER CHARGER ASSEMBLY ON BOARD...

Page 54: ...S 20 AUTO SCRUBBER WIRING DIAGRAM TRACTION DRIVE DISK...

Page 55: ...S 20 AUTO SCRUBBER WIRING DIAGRAM PAD BRUSH ASSIST DISK...