IMPORTANT SAFETY INSTRUCTIONS

READ AND UNDERSTAND ALL WARNINGS AND INSTRUCTIONS

BEFORE USING THIS APPLIANCE!

WARNING! To reduce the risk of fire, electric shock, or injury:

1.

Unplug from outlet when not in use and before servicing.

2.

Do not use outdoors. Protect the machine from rain.

3.

Do not allow to be used as a toy. Close attention is necessary when used by or near children.

4.

Use only as described in this manual.

5.

Never use this machine to pick up volatile or explosive materials!

6.

Do not use this machine for pick up of dust or dry debris.

7.

Do not use with damaged cord or plug. If appliance should not work as it should, has been dropped or

damaged, left outdoors, or dropped into water, return it to service center.

8.

Do not pull or carry by cord, use cord as handle, close a door on cord or pull cord around sharp

edges or corners. Do not run appliance over cord. Keep cord away from heated surfaces.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord

10. Do not handle plug or appliance with wet hands. Do not immerse. Keep the machine in a dry building.

11. Do not put any objects into opening. Do not use with any opening blocked: keep free of dust, lint,

hair and anything that may reduce airflow.

12. Keep hair, loose clothing, fingers and all parts of the body away from openings and moving parts.

13. Turn off all controls before unplugging.

14. Do not use in areas where flammable or combustible liquids such as gasoline may be present.

15. Connect to a properly grounded outlet only.

16. Do not use water that is hotter than 82

°

C (180

°

F).

17. To prevent damage to the solution system, do not store in freezing temperatures without proper maintenance.

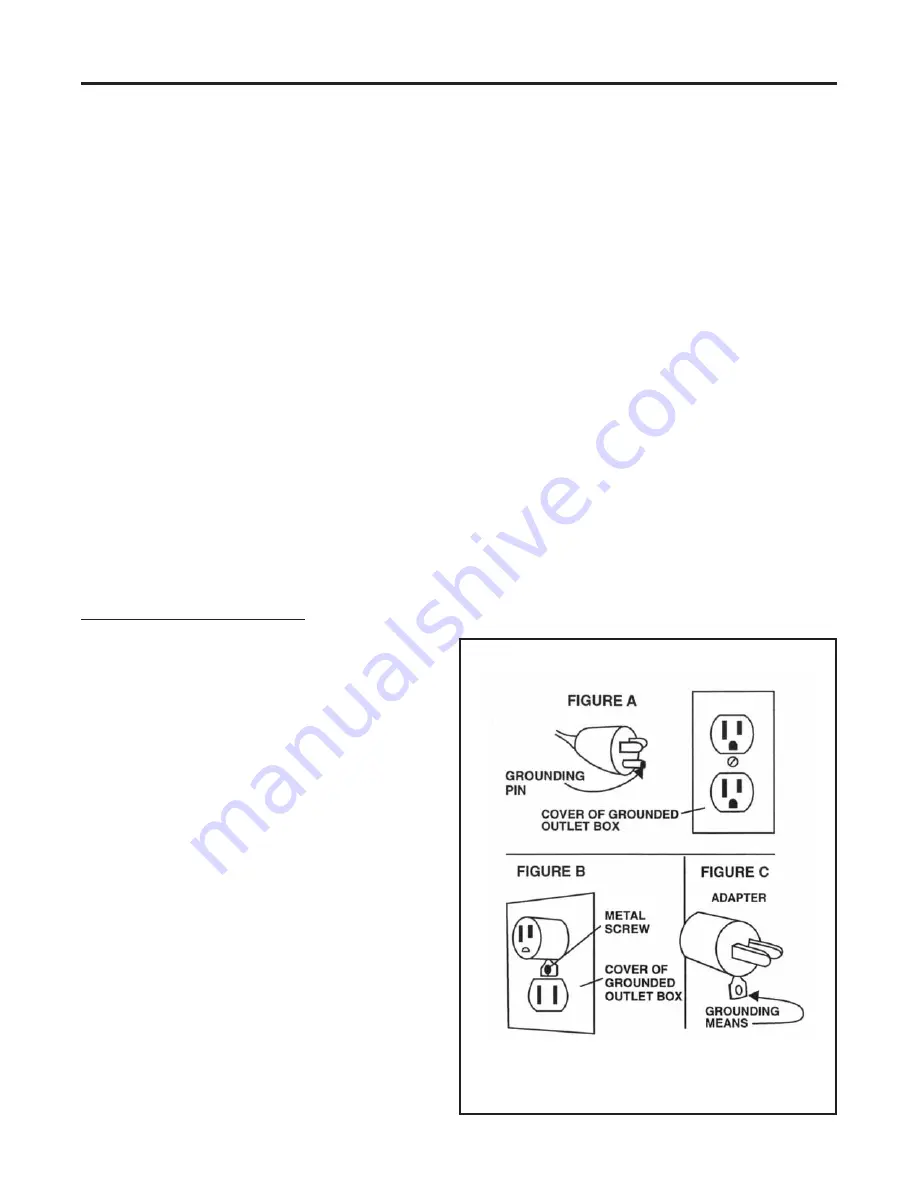

This machine must be grounded. If it should malfunction or break down,

grounding provides a path of least resistance for electric current to reduce the

risk of electric shock. This machine is equipped with a cord having an equip-

ment-grounding conductor and grounding plug. The plug must be inserted

into an appropriate outlet that is properly installed and grounded in accor-

dance with all local codes and ordinances.

WARNING

- Improper connection of the equipment-grounding conductor

can result in a risk of electric shock. Check with a qualified electrician or

service person if you are in doubt as to whether the outlet is properly grounded.

Do not modify the plug provided with the machine - if it will not fit the outlet,

have a proper outlet installed by a qualified electrician.

This machine is for use on a nominal 120-volt circuit, and has a grounded

plug that looks like the plug illustrated in figure A. A temporary adapter that

looks like the adapter illustrated in figures B and C may be used to connect

this plug to a 2-pole receptacle as shown in figure B if a properly grounded

outlet is not available. The temporary adapter should be used only until a

properly grounded outlet (figure A) can be installed by a qualified electri-

cian. The green colored rigid ear, lug, or the like extending from the adapter

must be connected to a permanent ground such as a properly grounded outlet

box cover. Whenever the adapter is used, it must be held in place by a metal

screw.

NOTE: In Canada, the use of a temporary adapter is not permitted by the

Canadian Electrical Code

EXTENSION CORDS

Use only three-wire 14/3 or larger gauge approved extension cords

that have three-prong grounding type plugs and three-pole recep-

tacles that accept the appliance’s plug. Replace or repair any dam-

aged cords or plugs.

When servicing, refer to authorized person only. Use only identical replace-

ment parts.

Grounding Instructions

NOTE:

Do not use adapters shown in figures B & C in Canada

Summary of Contents for Triumph 1200

Page 5: ...TRIUMPH 1200 FINALASSEMBLY 4 6 7 8 9 10 11...

Page 7: ...TRIUMPH 1200 RECOVERYTANK 6...

Page 9: ...TRIUMPH 1200 SOLUTIONTANK 8...

Page 11: ...TRIUMPH 1200 BASEASSEMBLY 10...

Page 13: ...TRIUMPH 1200 HOSEASSEMBLY 12...

Page 15: ...TRIUMPH 1200 WANDASSEMBLY 14 1 2 3 4 5 6 7 6 8 9 10 11 12...

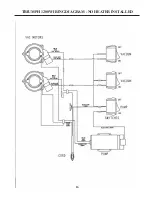

Page 17: ...16 TRIUMPH 1200WIRINGDIAGRAM NO HEATER INSTALLED...

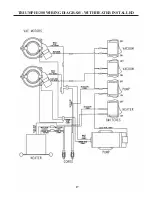

Page 18: ...17 TRIUMPH 1200WIRINGDIAGRAM WITH HEATER INSTALLED...

Page 19: ...NOTES 18...