Page 13 of 38

DAILY MACHINE MAINTENANCE

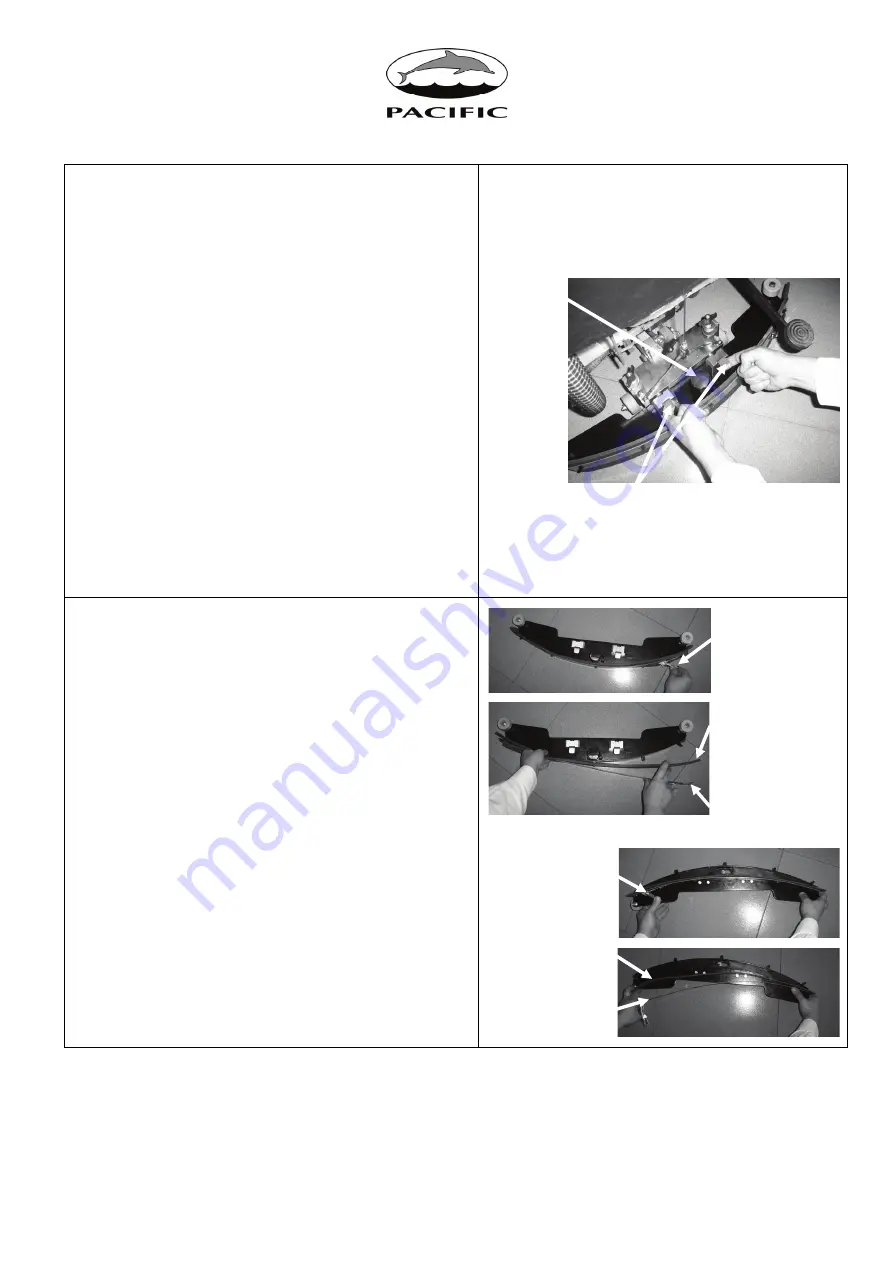

CLEANING THE SQUEEGEE

To obtain the best drying results, keep the

squeegee clean.

To clean the squeegee it is

necessary to:

13) Remove the vacuum hose from the

squeegee.

14) Lift locking latches. Remove the squeegee

assembly by pulling rearward.

15) Clean the inside of the squeegee thoroughly.

16) Clean the squeegee blades thoroughly.

17) Reassemble.

REPLACING THE SQUEEGEE BLADES

Check the squeegee blades for wear and if

necessary, change them.

To replace the

squeegee blades:

18) Remove the squeegee vacuum hose from its

port.

19) Lift locking latches and pull squeegee

assembly rearward.

20) Release the band clamps by lifting the band

clamp latch.

21) Remove squeegee blades.

22) Rotate or replace the blades. Please note

that the squeegee has 4 useable edges so

you may be able to rotate squeegee blades.

23) To reassemble the squeegee, repeat the

above operations in reverse.

Locking Latches

Vacuum

Outlet

Band

Clamp

Latch

Band

Clamp

Latch

Band

Clamp

Squeegee

Blade

Band

Clamp

Squeegee

Blade

Summary of Contents for Z210

Page 18: ...Page 18 of 38 Brush Deck Assembly Drawing 1...

Page 20: ...Page 20 of 38 Brush Base Assembly Drawing 2...

Page 22: ...Page 22 of 38 Main Frame Assembly Drawing 3...

Page 24: ...Page 24 of 38 Squeegee Arm Assembly Drawing 4...

Page 26: ...Page 26 of 38 Squeegee Assembly Drawing 5...

Page 28: ...Page 28 of 38 Solution Tank Assembly Drawing 6...

Page 30: ...Page 30 of 38 Recovery Tank Assembly Drawing 7...

Page 32: ...Page 32 of 38 Vacuum Assembly Drawing 8...

Page 34: ...Page 34 of 38 Switch Box Assembly Drawing 9...

Page 36: ...Page 36 of 38 Electrical Schematic Drawing 10...