| 14

PARTS ADJUSTMENTS

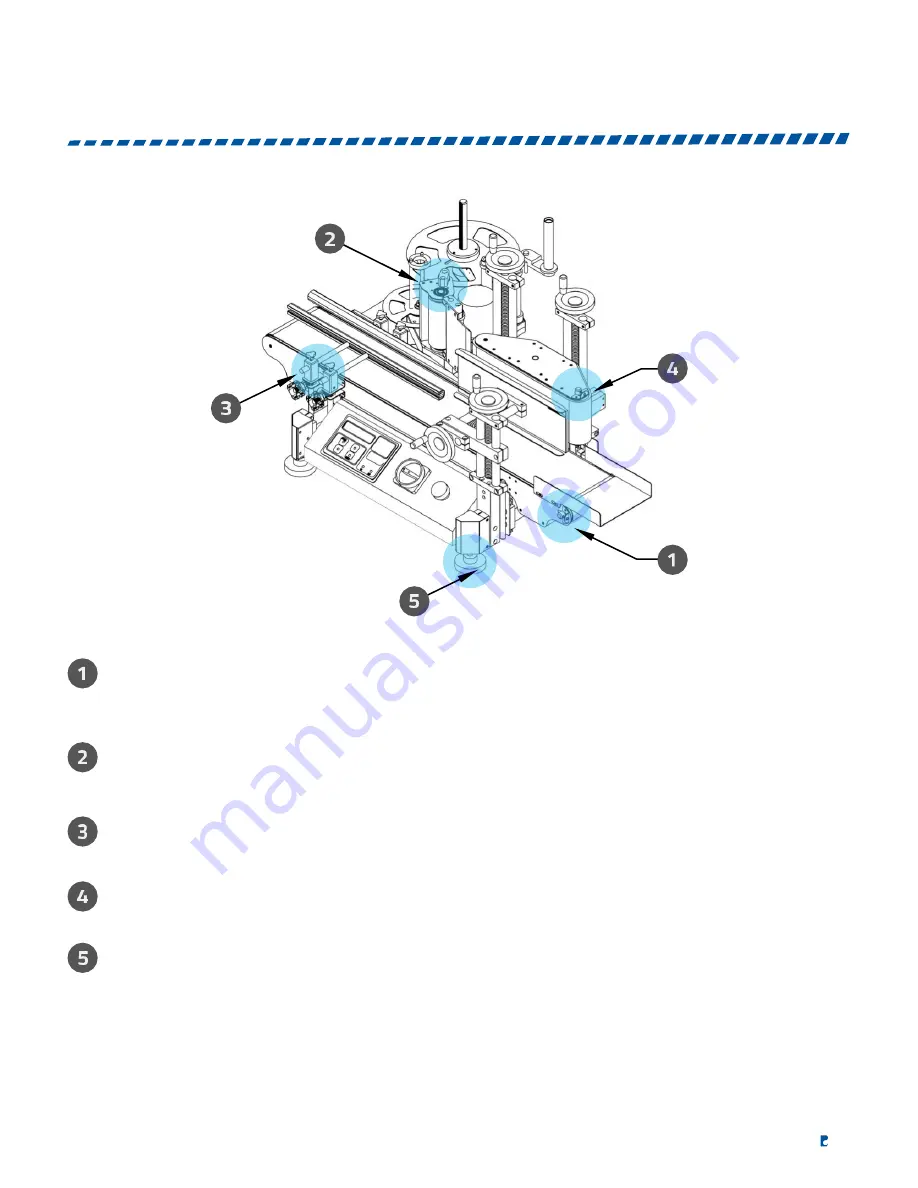

Conveyor adjustment:

To adjust the tightness of the conveyor belt, turn the two screws. Turn

counter clockwise to loosen and clockwise to tighten. Make sure the conveyor is centered. If not, it

can cause the belt to wear prematurely.

Dispensing adjustment screw:

If the label is skewing up or down all the time, loosen the four

screws and adjust the dispensing plate upward if the label is skewing upward or vice versa and then

tighten them up.

Guide rail adjustment screws:

To adjust the width of the conveyor guides, loosen the knobs and

adjust the position. Tighten after the desired width has been adjusted.

Wrap around belt adjustment:

To adjust the tightness of wrap around belt, loosen the four screws

and extend the pillar until the desired tightness is achieved and then tighten them up.

Conveyor height adjustment:

Adjust the four footing screw to adjust conveyor to the appropriate height.

Summary of Contents for ELF-50

Page 3: ...MACHINE SPECIFICATIONS ...

Page 5: ... 5 MACHINE DIMENSIONS 1101 mm 472 mm 1017 mm ...

Page 8: ...GENERALINFORMATION ...

Page 16: ...MACHINEOPERATION ...

Page 24: ...ELECTRONICPANEL ...

Page 25: ...ELECTRONIC DIAGRAM 25 ...

Page 26: ... 26 CONTROL BOX FRAME ...

Page 28: ...APPLICATOR ...

Page 30: ... 30 APPLICATOR MOTOR ASSEMBLY ...

Page 47: ...WRAPSTATION ...

Page 55: ...PRESSUREPLATE ...

Page 58: ...CONVEYOR ...

Page 59: ...CONVEYOR ASSEMBLY 59 ...

Page 64: ...FOOTSTAND ...

Page 65: ...FOOT STAND ASSEMBLY 65 ...

Page 67: ... 67 FOOT STAND ASSEMBLY PART LIST IN FEED TURNTABLE ...

Page 73: ... 73 IN FEED HOLDER ASSEMBLY 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 ...

Page 75: ... 75 OUT FEED TURNTABLE ASSEMBLY OUT FEED TURNTABLE ...