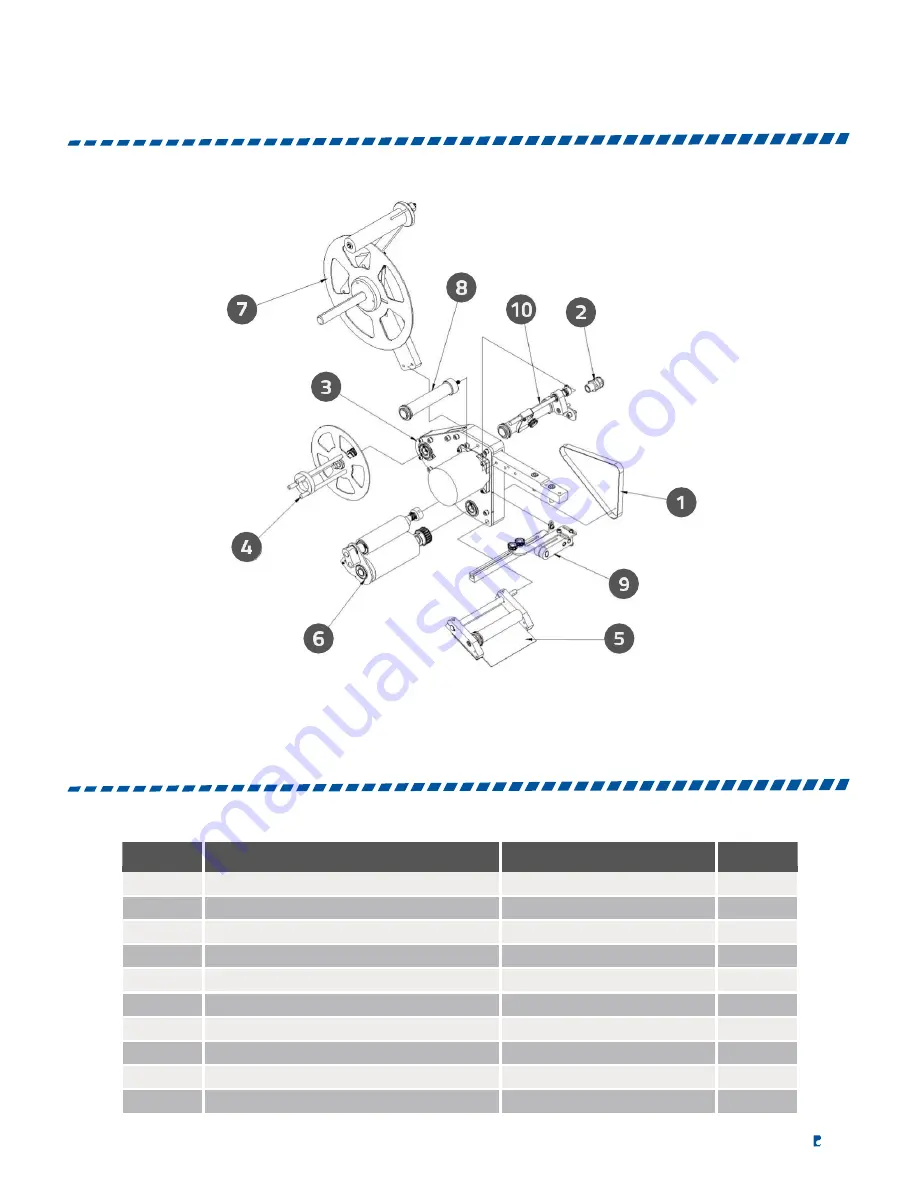

APPLICATOR EXPLODED VIEW

| 29

APPLICATOR EXPLODED VIEW PART LIST

NO.

DESCRIPTION

PARTS NO.

QTY.

1

Timing Belt 200XL050

T2Q2-200XL050

1

2

Cable Connector

QVQR-MG16A-10B

1

3

Applicator Motor Assembly

1

4

Base Paper Collect Assembly

1

5

Label Peel Plate Assembly

ELF1050501

1

6

Applicator Driving Assembly

1

7

Label Supply Plate Assembly

1

8

Label Roller Assembly

1

9

Label Sensor Base Assembly

1

10

Label Load Assembly (Without Printer)

1

Summary of Contents for ELF-50

Page 3: ...MACHINE SPECIFICATIONS ...

Page 5: ... 5 MACHINE DIMENSIONS 1101 mm 472 mm 1017 mm ...

Page 8: ...GENERALINFORMATION ...

Page 16: ...MACHINEOPERATION ...

Page 24: ...ELECTRONICPANEL ...

Page 25: ...ELECTRONIC DIAGRAM 25 ...

Page 26: ... 26 CONTROL BOX FRAME ...

Page 28: ...APPLICATOR ...

Page 30: ... 30 APPLICATOR MOTOR ASSEMBLY ...

Page 47: ...WRAPSTATION ...

Page 55: ...PRESSUREPLATE ...

Page 58: ...CONVEYOR ...

Page 59: ...CONVEYOR ASSEMBLY 59 ...

Page 64: ...FOOTSTAND ...

Page 65: ...FOOT STAND ASSEMBLY 65 ...

Page 67: ... 67 FOOT STAND ASSEMBLY PART LIST IN FEED TURNTABLE ...

Page 73: ... 73 IN FEED HOLDER ASSEMBLY 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 ...

Page 75: ... 75 OUT FEED TURNTABLE ASSEMBLY OUT FEED TURNTABLE ...