Commercial Back Pack

Vacuum Cleaner

Revised: January 2013

www.pacvac.com

Support: 08 9479 1444

www.pacvac.com

Support: 08 9479 1444

Part No. UA908

Combination floor tool

Part No. UA9272

Bottom plate to suit

combination floor tool

Part No. UA917H

All purpose floor tool

Part No. UA926

Turbo head

Part No. UP112PB

Plug in RCD adaptor

Part No. UA908W

Combination floor

tool with wheels

Part No. KC909

Extendable wand

Part No. UA913M

Metal bent hand piece

NOTE: Not suitable for

commercial use

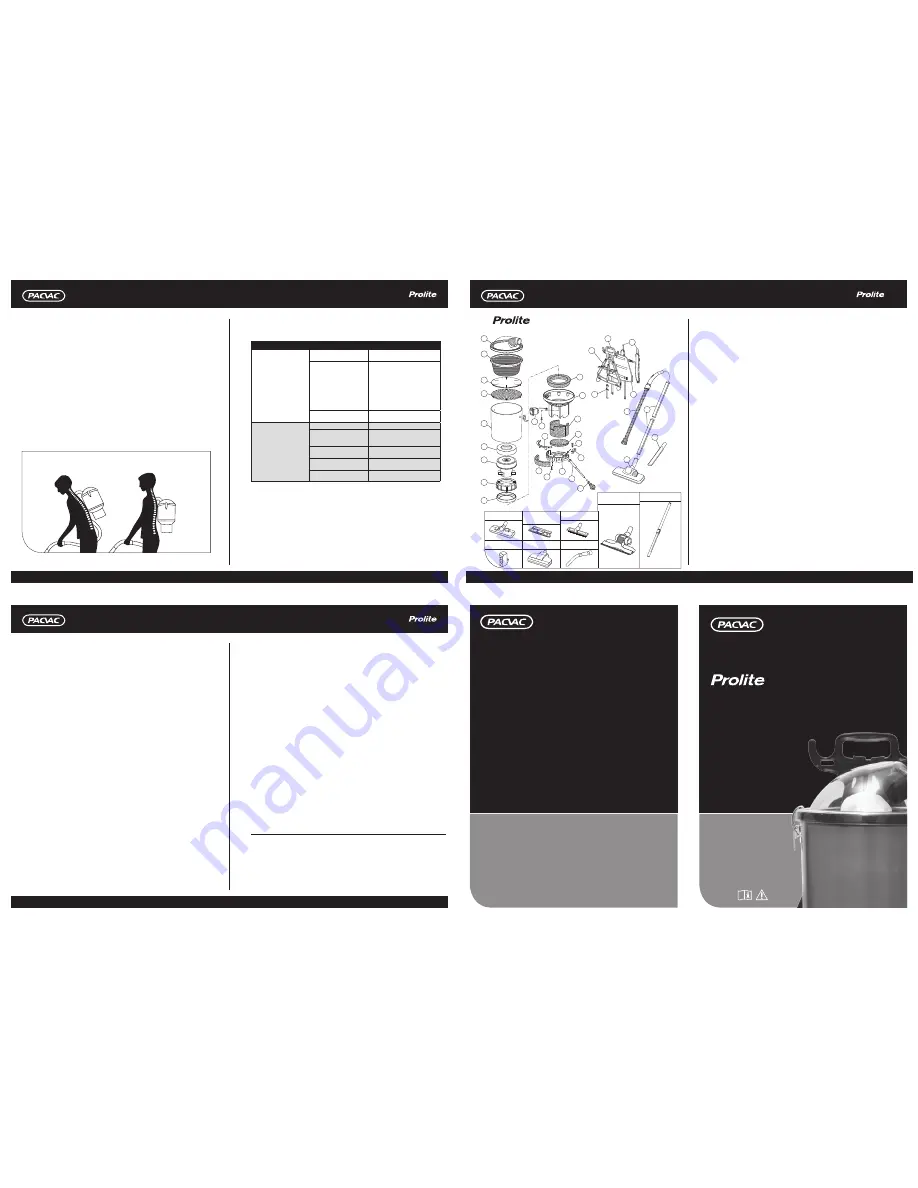

13. Parts Profile

Quote these part numbers when ordering spare parts

No. Part Name

Part No.

1.

Dome lid

KC251

2.

Dust bag flat bottom

P502

3.

Prolite filter (Packet of 5)

KC522A5

4.

Filter retainer

KC522

5.

Main vacuum canister

KC252P

6.

Motor gasket foam

KC253B

7.

Motor 240v 1300W single stage flow through

G118

8.

Motor spacer

KC253S

9.

Motor gasket

KC253

10.

Intermediate noise insulation

P254

11.

Intermediate housing

KC256P

12.

Switch rocker 12A 250V 5E4

VS261

13.

Screw pan plastite 5x20

N/A

14.

Noise insulation motor

P255

15.

Noise insulation bottom lid

P255B

16.

Screw pan plastite 3x12

PV299

17.

Cable clamp

KC262

18.

Motor filter cage

KC264

19.

External noise insulation

P259

20.

Screw ST 6x25

N/A

21.

Bottom cap

KC258

22.

Cable grommet

KC406

23.

Power cord 15m 10A 2c 1mm2 (AU, NZ)

KC111

Power cord 15m 10A 2c 1mm2 (UK, SG, IN, AE)

KC108UK

Power cord 15m 10A 2c 1mm2 (EU)

KC108EU

24.

Bolt 5x20

N/A

Nut 5mm nyloc

N/A

Washers 3/16 x3/4 & 3/16 x7/16

N/A

25.

Carrying frame

KC120

26.

Shoulder strap pair

KC121

27.

Cord restraint

KC268

28.

Back support padding

KC263

29.

Hose complete 32mm 1.2m

KC32PRO

30.

Two piece wand

KC9092

31.

Crevice tool

KC911

32.

KC floor tool

KC908W

www.pacvac.com

Support: 08 9479 1444

Product & Training Manual

Service & Help

For service and help contact Pacvac on 08 9479 1444

or visit our website at www.pacvac.com for a list of your nearest

Gold Level Retailers and Service Centres.

Support: 08 9479 1444

www.pacvac.com

Read the instruction manual before using the machine.

Retain for future reference.

Original

Instructions

Caution: Always unplug the back pack before attempting to solve a problem

or when servicing

11. Troubleshooting

10. Operate Right

How to vacuum easier and faster with no back strain.

1. Stand upright, with the bent hand piece section parallel to the floor.

2. Hold the bent hand piece with one hand at a comfortable arm’s length.

3. Move forward and away from the power point.

4. Use easy underarm swinging motion when detail cleaning and short dabs when spot

cleaning, always standing upright.

5. Once the end of the power cord has been reached and work completed, return to the

power point along the cord line and disconnect the power cord from the power point.

6. If work is not completed move to the next area, connect power cord to the nearest power

point and repeat steps 1 through 6.

7. Remove back pack by sliding the one of the straps off the shoulder, while raising the other

arm/shoulder to hold strap in place. Slowly lower the shoulder and lower the back pack to

the floor,

do not drop

.

8. If work is completed disconnect power cord from power point then wind from the back pack

towards the end of the power cord to reduce likelihood of cable twists. In the process check

for nicks, cuts, fractures, and knots.

4

6

PROBLEM:

CAUSE:

SOLUTION:

Back Pack not working

Power cord not firmly plugged

into power point.

Check plug is firmly plugged in.

Back pack shuts off due to

high motor temperature.

Turn main switch off and unplug

the back pack. Conduct safety and

maintenance checks found in the

Product and Training Manual or as

per labelling on the machine. After

60 the back pack should be ready

for use. If not contact the number

below for your nearest Authorised

Pacvac Service Agent.

Circuit breaker or RCD has

tripped.

Reset circuit breaker or RCD.

Back Pack as no/poor

suction

Dust bag is full.

Remove, empty and clean dust bag.

Dust bag not installed

correctly.

Remove and empty dust bag making

sure the rubber edging is correctly

fitted around the canister.

Hose not installed correctly.

Reconnect hose and ensure

correctly sealed.

Blockages.

Remove hose, wand and floor tools;

remove any blockages.

Filters blocked.

Clean Hypercone HEPA filter and

external motor filter.

Product Number: 201006-002A

Specifications

Volts / Frequency: 220-240V~50Hz

Motor: 1300W Single Stage Flow Through

Noise Level: 66dB(A)

±

3dB(A) (at 1.5m)

Filtration: 3 stage

Airflow Volume: 39 litres per sec

Tank: Capacity: 6 litres

Weight: 4.6kgs (excluding power cord and hose)

15. Notes

14. International Authorised Distributors

INDIA

Inventa Cleantec Pvt Ltd

C-31 Sector 63

NOIDA

Distt. Gautam Budh Nagar 201 301

INDIA

Ph: + 91 120 2401086

Fax: + 91 120 2401087

Web: www.inventacleantec.com

JAPAN

Bl Corporation

6-62-12 Shibayama

Funabashi-shi, Chiba-Ken 274-0816

Japan

Ph: + 81 47 464 1462

Fax: + 81 47 464 1477

Web: www.bicorp.co.jp

NEW ZEALAND

Proquip NZ Ltd

47 Fitzherbert Street,

Petone

Wellington

New Zealand

Ph: + 64 4 566 7847

Fax: + 64 4 576 0430

Web: www.cleangear.co.nz

NORWAY

Viking Cimex AS

Prof. Birkelandsvei 24 A-1

1081 Oslo

Norway

Ph: 47 22 79 35 35

Fx: 47 22 79 35 40

Web: www.skovly.no

SINGAPORE

Klenco (Singapore) Pte Ltd

18 Gul Crescent,

Singapore 629527

Ph: + 65 6862 3388

Fax: + 65 6861 7575

Web: www.klenco-asia.com

SLOVENIA

Klimatehnik d.o.o.

Brnciceva ulica 13

1231 Ljubljana

Slovenia

Ph: +386 4 180 5004

Fax: +386 1 781 6040

Web: www.klimatehnik.si

SOUTH AFRICA

Industro Clean

1490 Zeiss Road

Lazer Park

Honeydew

South Africa 2125

Ph: +27 11 801 4600

Fax: +27 11 794 3504

Web: www.industroclean.co.za

UNITED KINGDOM

TML International Ltd

Woodlands

Copmanthorpe Grange

Copmanthorpe

York Y023 3TN

United Kingdom

Ph: +44 (0) 1904 744790

Fax: +44 (0) 1904 744010

Web: www.tmlint.com

UNITED STATES OF AMERICA

TTI Floorcare North America

7005 Cochran Road

Glenwillow, OH 44139

United States of America

Ph: +1 440 996 2178

Fax: +1 440 996 2026

Web: http://ttifloorcare.com

AUSTRALIA:

For your nearest Australian Retailer/Service Centre contact:

Pacvac Pty Ltd

182 Daly Street, BELMONT, 6104

WESTERN AUSTRALIA, AUSTRALIA

Ph: + 61 8 9479 1444

Fax: + 61 8 9478 5444

Email: sales@pacvac.com

Web: www.pacvac.com

Optional Extras

1

2

3

4

5

6

7

8

9

10

11

12

13

14

16

17

22

21

20

19

18

15

23

24

25

26

27

28

29

30

31

32

12. Service Requirements

Our products are designed and built to be functional and durable. As a result, if you maintain

your vacuum cleaner as instructed, it is unlikely to require servicing. For information on use

and maintenance please read the Product and Training Manual thoroughly. Should you require

servicing we recommend our Pacvac Gold Level Service Centres. For your nearest centre visit

www.pacvac.com, alternatively contact Pacvac on 08 9479 1444 or e-mail sales@pacvac.com.