©2020 PACE Inc., Vass, North Carolina,

All Rights Reserved

Page

23

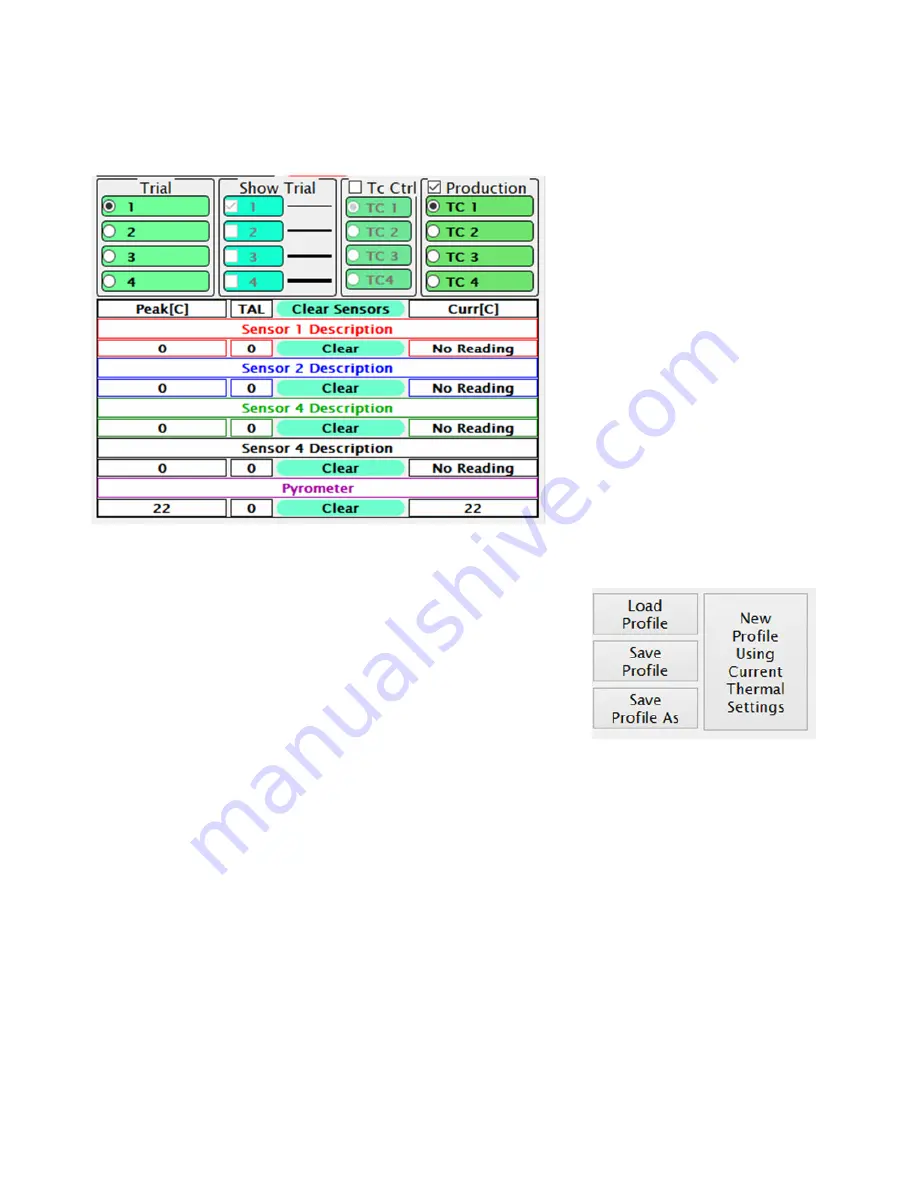

During the profile development process, up to 4 “trial runs” can be made/viewed for comparing and

contrasting how well different settings work on a given application. The information displayed in each trial run

can be altered using the buttons and check boxes above the temperature sensor readouts.

•

Trial Number – This column

designates which trial run is currently

active for editing or being saved to the

finished profile for reference in

production runs.

•

Show Trial – Select which trial run

profile graphs are currently visible.

•

Tc Ctrl –Use this to select one of the

external thermocouple sensors instead

of the pyrometer for controlling the

temperature during a profile run.

•

Production – Select external

thermocouple temperature graph(s) to

be visible as reference during production

runs of the profile.

Sensor descriptions can be changed by the profile developer to better indicate to the production user where

the sensors were located during profile creation.

Your new IR machine will come with default installation and

removal profiles. These can be used as starting points for new custom

profiles. The IR software will memorize the distance traveled by the

heater head during some parts of an installation or removal process. The

included default profiles do not have any distances stored. When altering

any other pre-existing profile to work with different components, after

loading the profile you must clear the distance settings with the “New

Profile” button or the heater head could crash.

Following is a sample outline of steps needed to develop an installation profile by doing a new

component installation. The process is essentially the same as doing a production run, except with the ability to

make changes.

1. Turn on the IR machine and the PC, then start the PACE software.

2. Navigate to the Developer Mode screen if not already there.

3. Load a profile using the Load Profile button.

4. Install the proper vacuum pick.

5. Click “Start Process” and follow the onscreen instructions which will guide you through the

following steps.

6. Place the PCB between the arms of the board holder and position the board so the red

laser point is roughly in the center of the component placement site then tighten the

retention screw.

7. Apply flux to the board if needed, and attach any thermocouples desired for additional

process monitoring. Adjust the board support to the middle of the board.

8. Place the component in the mounting plate on top of the camera housing. Click “okay”.

9. The BGA workstation will pick up component. If the vacuum pick fails to pick up the

component, reset the component in the nest and click “Retry”.