36

GTV

FORCED CONVECTION AIR HEATERS

Instructions for Installation and Servicing

Maintenance supervision solely by a qualified service department

(all kinds of interventions for which disassembly of appliance is necessary):

•

supervision of nozzle pressure (at the outlet of solenoid valve),

•

check of the condition of pressure regulator

•

check of the protective ground

•

check of the electrical connection

•

check of the exhaust fan and circulating fan: check the free rotation of fan and remove the possible contaminations from

the impellers

•

supervision of the heat exchanger

•

supervision of working of the temperature controller

•

check of the ignition and ionization electrode, if necessary change it

•

check of the exhaust fan and circulating fan, if necessary clean those

•

supervision of the quality of combustion

• dismounting and clean of the gas filter by high pressure air

ATTENTION! After every maintenance the appliance must be again adjusted !

Constructional components,which ensure the suitable operation:

•

double-closed solenoid valve

•

automatic burner control

•

electrical board (sign processing)

•

differential pressure switch

•

exhaust fan

•

combined thermostat (bimetal),

•

heat-limiter thermostat (100 °C),

•

circulating fan

WARNING! Never block the outflow of fume and inflow of combustion air!

Never change the original adjustments what the expert made!

Never allow that water or water –vapour can be got on the appliance!

Apart from cleaning of exhaust fan and circulating fan the a�m� components do not need maintenance! The cleaning of fans is expedi-

ent to carry out by high pressure air�

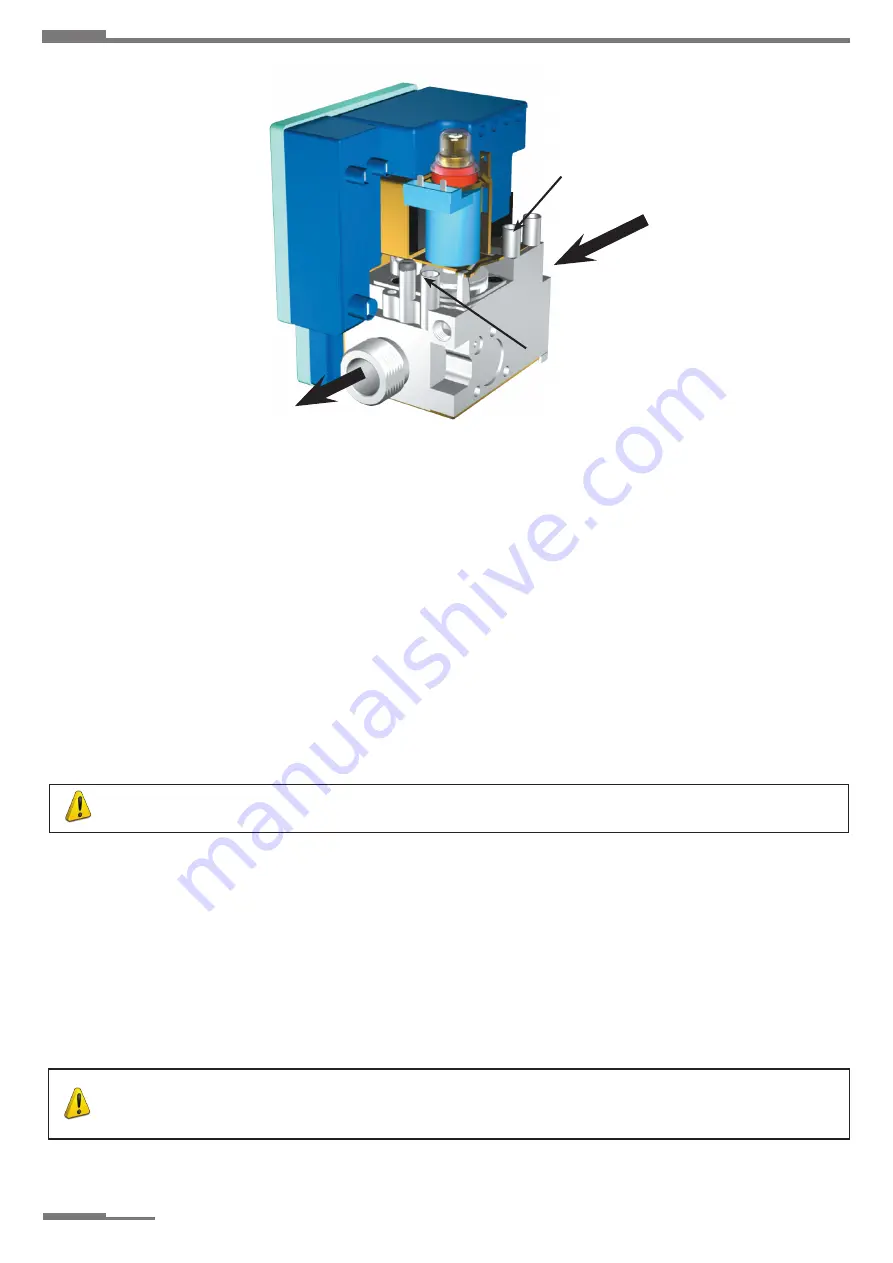

input

gas flow

direction

gas flow

direction

output

42. picture: Gas pressure check with SIT magnetic valve