5

GTV

FORCED CONVECTION AIR HEATERS

Instructions for Installation and Servicing

•

Make sure that read and understood all the warnings, correct keeping of which can guarantee the safety and faultless operation !

•

During the installation be always circumspect! Follow the valid instructions and recommendations!

•

The appliance can be operated by specified voltage and frequency marked on its data board! The electrical connections and

groundings are prepared as per standard!

•

Electrical grounding specification: present appliance is equipped with three points grounding connection in the interests of your

protection!

•

It needed to ensure the sufficient quantity of combustion air if the appliance is installed without outside air supply!

•

Keep away the device from the following strong effects: wind, high pressure water jet, rain or dropping water!

•

The appliance must not be used in the open air!

•

The application of device is STRICTLY PROHIBITED in such rooms, which are used for sleep or continuous stay!

•

Keep away the flammable materials from the appliance and its near environment as follows: fuels,thinner or other flammable

fluids and vapours!

•

In the interests of avoiding of dust explosion do not used the device in such rooms where the degree of dust concentration is

high if the device is installed without outside air supply!

•

Before starting of appliance in every case check it in order to detect the possible damages! Never use damaged equipment!

•

In case of propane gas operation never install the device in basement or from that lower being rooms! The propane gas is

heavier specific gravity than the air for this reason in case of possible escaping it will spread towards the lower located rooms !

•

Only use that kind of flexible gas pipe and pressure regulator, which is offered for the appliance by the manufacturer!

•

Before every starting of heater appliance check the condition of connecting gas hose and if it is particularly worn or damaged in

that case exchange it for a new one specified by manufacturer!

•

Preserve the equipment in genuine condition, do not leave it to grow old!

•

Do not use seriously aged equipment any longer!

•

Fix the appliance on such stable surface, which during operation despite warming of appliance preserves its stability !

•

If the appliance is put out of use in every case it must be cut off the current and gas!

•

Never block the air supply and exhaust pipes!

•

Keep away the children and animals from the equipment!

•

Never service/mend such devices, which are hot and during operation or electrical charged!

•

Never mount such air duct unit on front or back side of device, which is not approved by manufacturer!

•

Use exclusively genuine-approved by manufacturer-spare parts,do not install similar quality spare parts for substitution! These

kind of substitute parts can cause serious damages concerning the operation of appliance!

•

Fix the appliance on such stable surface, which during operation despite warming of appliance preserves its stability !

•

If the appliance is put out of use in every case it must be cut off the current and gas!

•

Never block the air supply and exhaust pipes!

•

Keep away the children and animals from the equipment!

•

Never service/mend such devices, which are hot and during operation or electrical charged!

•

Never mount such air duct unit on front or back side of device, which is not approved by manufacturer!

•

Use exclusively genuine-approved by manufacturer-spare parts,do not install similar quality spare parts for substitution! These

kind of substitute parts can cause serious damages concerning the operation of appliance!

• making up of gas and electrical connection in compliance with the specifications (it is proposed to connect with the local Building

Supervisory Authority or Fire-service),

• installation of equipment in accordance with the definitions of this manual,

• installation according to the fire prevention rules,

•

supply of the necessary materials/components for installation(which are not belong to appliance),

•

planing of air duct systems (ventilation/connections)

•

service execution,

•

placing the copy of present manual at owner’s disposal,

• assuring of sufficient air circulation around the appliance,

• determination and assuring of needed air for burning, ventilation and blowing in according to the specifications.

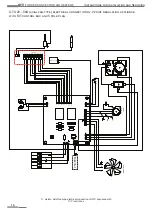

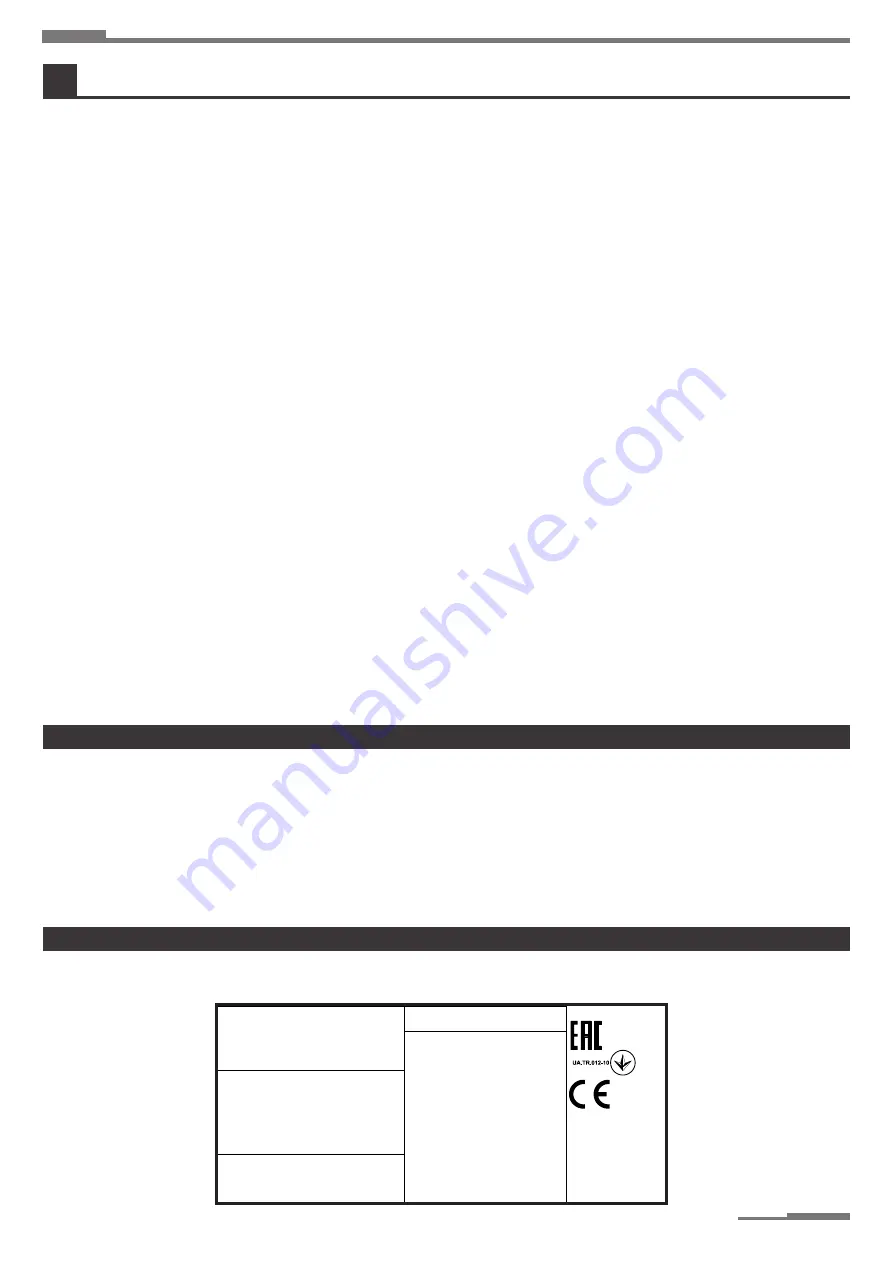

The appliance is equipped with data board, which is placed on inside of device’s door� On this data board there are information concern-

ing the type of device, gas type, electrical connection and flue types.

1. picture: Data board

2.

General Instruction

Installer’s responsibilities

Data board

II2H3P

PAKOLE Trade Kft.

8000 Székesfehérvár,

Börgöndi út 8-10.

Pconnecting min.:

20 mbar

437 W

Category:

Electrical power:

30 Pa

Stat. air pressure:

5010 m³/h

Manufacturer

Type

Nominal input:

47,3 kW

Naturalgas

Pconnecting max.:

51-7445-1

Series number:

GB

Targeted country:

Gas type:

Electrical protection:

Electrical connection:

Max.current entry:

IP20

AC 230V 50Hz

Date/place of production

21.08.2019

60 mbar

2,8 A

Airflow:

Jet pressure:

7 mbar

GTV-48A

NOx

4

PIN:

1008 CQ 2928

1008 18