2

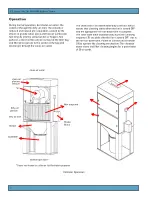

Description

The Unimaster series dust collectors are self-contained,

intermittent-duty dust collectors with bag style filters.

This durable collector provides effective cleaning in a

variety of industrial settings.

This collector can be used as a collector complete with

legs, hopper and bin or 55 gallon drum for collecting the

dust, or it can be configured without legs and hopper to

be used for bin venting applications.

Standard sizes range from 43 to 753 sq ft of filter area and

features a UMA controller to control the filter cleaning

operation. Other options include explosion relief vents,

static grounding, weather hoods and caster frames.

Purpose and Intended Use

Misuse or modification of this

equipment may result in personal

injury.

Do not misuse or modify.

The Unimaster dust collectors are used to separate solid

particulate from an airstream as part of a manufacturing

process. It is an ideal choice for intermittent operations

in plant processes. Several small collectors can be

installed at dust generation sites throughout the plant

resulting in total dust capture and flexibility. Some typical

installations include blending/mixing, abrasive blasting,

cleaning, cutting, drilling, grinding, milling, packing,

polishing, sanding, and sawing.

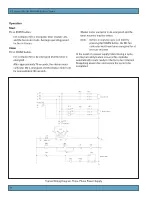

PZ Series 150-250-500-1000 Shaker Cleaner