25

51-4771

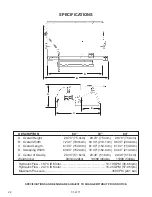

MAINTENANCE

REPLACING BEARING

1.

Remove the center M8 capscrew and the klik pins securing the bearing mounting plate

to the bearing assembly and side of sweeper.

2.

Remove the bearing flange from the mounting plate.

3.

Press out existing bearing and replace with new.

4.

Reinstall the bearing flange to the mounting plate using existing hardware.

5.

Reinstall by reversing steps #1 and #2.

KLIK PINS

M8 CAPSCREW

BEARING FLANGE

BEARING

BEARING MOUNTING

PLATE

SWEEPER