Palax KS50s

Translation

1-2012

35

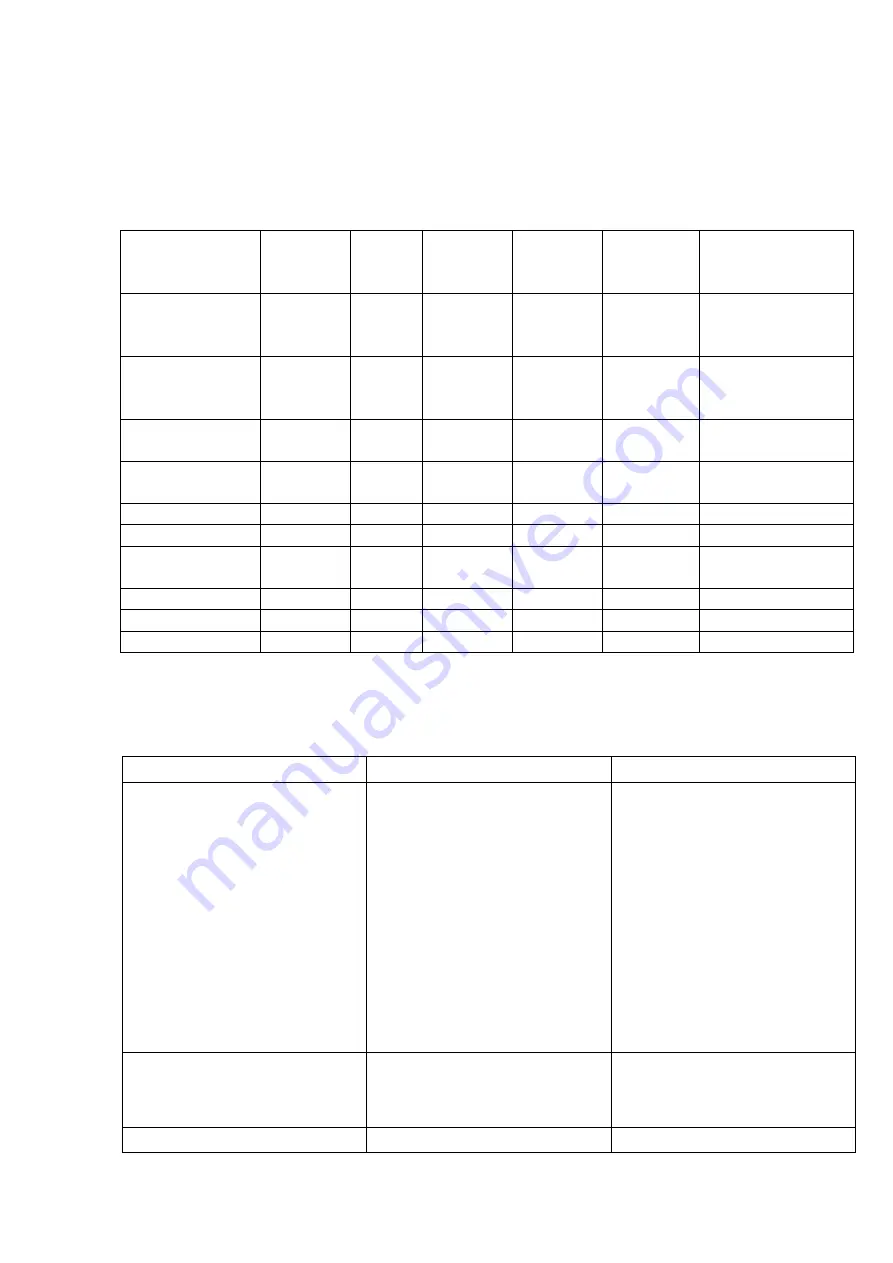

9 MAINTENANCE SCHEDULE

Object

Task

Daily

Service

interval

100 t

Service

interval

500 h

Service

interval

1000 h

Material /Method

Angular gear

TR–powered

Check

1 Change

2 Change

X

X

X

SAE 80 0.5 l

Suction drainage

Hydraulic oil

Normal conditions

Check

1 Change

2 Change

X

X

X

Volume 130 l

e.g. Esso Univis 32

Neste Hydrauli 32

Oil filters

1 Change

2 Change

X

X

FIO 100/ 3

Bearings requiring

lubrication

Lubrication

X

Ball-bearing lubricant

Splitting valve

Lubrication

X

Lubrication oil, spray

All levers

Lubrication X

Lubrication oil

Crosscut

saw-

blade

Sharpening

As required

Machine

Cleaning

X

Electric motor

Cleaning

X

Electric equipment Cleaning

X

10 MALFUNCTIONS AND THEIR REMEDY

Disturbance

Cause

Remedy

Splitting is not operational.

1. Protective net for splitting

chute is open.

2. No oil or too little oil.

3. Debris inside the launch

system.

4. The oil is too cold.

5. A hydraulic hose has

burst or is leaking.

6. The

splitting

system

does not move due to

freezing.

1. Close the protective net.

2. Stop

the

machine

immediately and top up

the oil.

3. Clean up the launch

system.

4. Allow the oil to circulate

at free-flow for a few

minutes.

5. Replace the hose.

6. Always

clean

the

machine when you stop

working.

Protective cover for the

splitting chute cannot be

opened.

1. The saw-shaft is not in

the upper position.

1. Lift up the saw-shaft

completely.

The splitting movement does 2. The setting of the locking 2. Adjust the locking device