3.

Operating the Roller

3.1. Hydraulic drive

Connect the hydraulic hoses so that the hydraulic flow direction is correct.

Adjust the rotating speed using the hydraulics’ speed adjustment valve.

3.2. Electrical drive

Make sure that the rotation direction of the screen and the output conveyor are correct.

If necessary, reverse the rotation direction by inverting the phase from the phase

inverter located in the plug.

Switch on the output conveyor and the screen before loading any wood into the Roller.

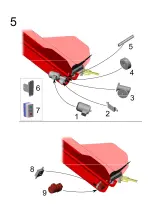

Switch on the screen by turning the starter switch to the right and press the start

button.

When Roller is stopped by pressing emergency stop or reversed it will start again by

pressing start button.

If the screen stops due to a jammed piece of firewood, etc., you can reverse it by

turning the switch to the left. The switch cannot be locked in the reverse position.

If the screen remains jammed for an extended period of time, the starter’s thermal relay

may trip. If this happens, turn the switch to the 0 position and reset the thermal relay by

pressing the R button.

When loading with a front loader, it is crucial that the Roller is only loaded with small

amounts of firewood at a time. Loading the Roller with a large amount of firewood at

once will reduce screening efficiency and may clog up the output conveyor.

3.3. Adjusting firewood throughput rate

The throughput rate of the firewood can be adjusted by adjusting the Roller’s angle.

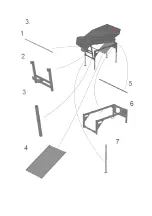

(Figure 1.)

In a hydraulic machine, the rotation speed of the screen and the output conveyor can

be adjusted by adjusting the speed adjustment valves next to the hydraulic motor.

There are separate valves for adjusting the screen and the conveyor.

When loading with a front loader, it is crucial that the Roller is only loaded with small

amounts of firewood at a time. Loading the Roller with a large amount of firewood at