31

ENGLISH

on the rear panel.

5.8.1

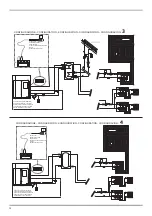

'HVFULSWLRQRIZDWHUFLUFXLW¿J

A) Pressure

gauge

B) Automatic release valve

C) Load

tap

D)

+RWZDWHUÀRZWRWKHV\VWHP*´)

E) Water return from the system (G3/4”F)

F) Safety valve (G3/4”F)

G) Closed expansion vessel

H) Circulator

I) Anti-condensation

valve

5.8.2

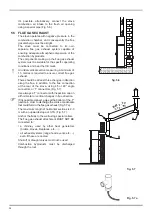

:DWHUFRQQHFWLRQV¿J

Connect the stove to the heating system via

WKHÀRZDQGUHWXUQSLSHV'(

Prepare a waste tube, of appropriate

diameter, which connects to the safety valve

(F) discharge.

After making the water connections, it is necessary

to proceed with the boiler load (tap C) and the

related vent (B), monitoring the pressure (1-1.2

bar cold) through the pressure gauge (A).

If necessary ensure that the closed expansion

vessel (G) preload is correct.

MAXIMUM OPERATING PRESSURE: 2,5 bar

It is good practice to proceed with washing the

system before commissioning the operational

system.

7RHQVXUHSHUPDQHQWKLJKHI¿FLHQF\DQGORQJOLIH

of the product, a water softener is recommended

to ensure that the water hardness of the system

is less than 25-27 French degrees and to add

anti-algae treatment to the system’s water as

necessary.

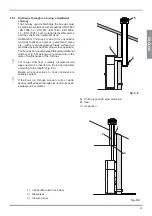

¿J

¿J

¿J

A

C

G

I

H

B

D

E

F

A