58

004778990 - 11/02/2022

Fig. 24

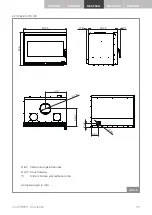

10.3 Routine maintenance

10.3.1 maintenance of flue manifold

Open the door and remove, in this order, the back

wall (

a

), the side walls (

B

) and the upper deflector

(

c

) (paragraph

"adjusting the bypass valve" on

page 53 - Fig. 18

).

Remove the flue manifold cap (

a

) (

Fig. 25

).

A

Fig. 25

Use a flexible brush to clean the pipes in the

combustion chamber (

Fig. 26

).

Remove any residues that fall in the flue manifold

using an ash vacuum.

Fig. 26

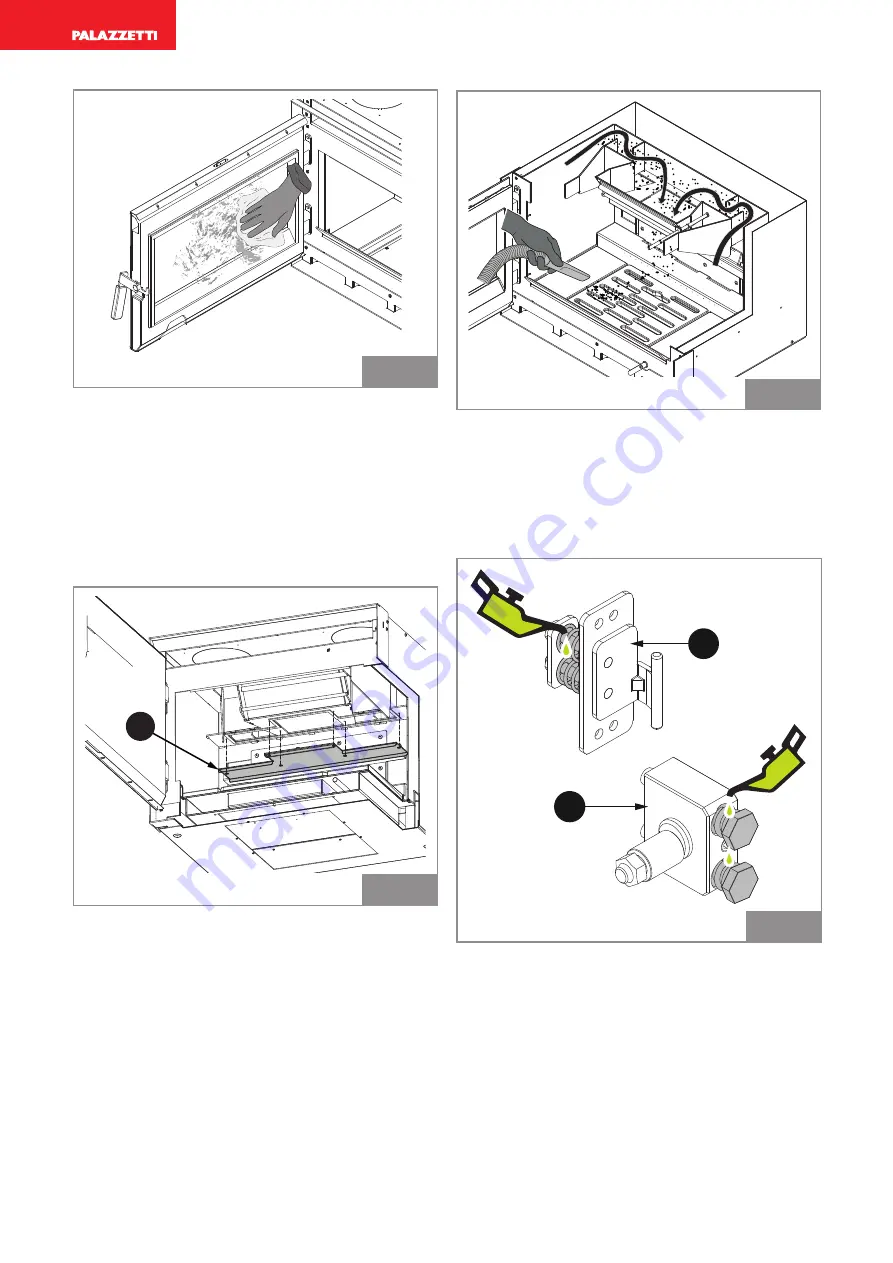

10.3.2 Door safety

In order to guarantee the correct and safe

operation of the fire box door, it is necessary to

lubricate the springs of the closing mechanism,

which may be located at the hinges (

a

) or at the

door closing latch (

B

).

B

A

Indicative image

Fig. 27

10.3.3 maintenance of the smoke system

To be carried out at least once a year, or every

4000 kg of fuel burned (as specified in the prod-

uct standard), by contacting specialist personnel

If there are horizontal sections, it is necessary to

check and remove any deposits of ash and soot

before they obstruct the passage of fumes.

The incrustations inside the flue affect the

optimum forced draught. When they reach a

thickness of 5-6 mm, with high temperatures