28

00 477 7300- 18/02/2019 - PALAZZETTI - PN - Italy

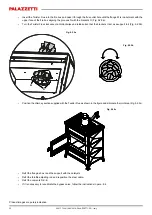

Fig. 7.5.3a

Fig. 7.5.3b

Fig. 7.5.3c

7.5.2 Secondary combustion

It is obtained by injecting preheated air into the fire

box through the holes on the upper part of the back

wall. Entering the fire box the air ignites unburnt gas

(carbon monoxide) formed by the primary combustion,

transforming it into carbon dioxide (CO2). The effect is

clearly visible with the formation of a belt of flames at the

secondary air inlet holes.

7.5.3 Cleaning the glass

During the operation of the stove, it is possible to facilitate

cleaning the ceramic glass through the pawl

without

having to open the door

(Fig. 7.5.3a - Fig. 7.5.3b).

This must normally be positioned towards closed flow.

If the pawl is moved, a flow of air opens up, striking the

surface of the ceramic glass, facilitating its cleaning.

To carry out this operation, use the one-finger glove

provided.

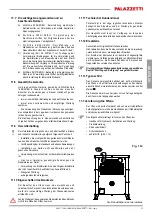

To perform complete cleaning of the glass it is necessary

to wait for the stove to go off and cool and to carry out

cleaning with the appliance cold.

It is performed with a damp cloth or with newspaper

paper, moistened and rubbed in the ash, rubbing the

glass until complete cleaning is obtained (Fig. 7.5.3c).

Sometimes this procedure may not be enough: at this

point it is possible to use specific detergents, taking care

to spray the product onto a dry cloth and not directly onto

the glass of the stove or onto the surrounding painted

parts.

Under normal conditions the glass tends to blacken

during ignition and to lighten during operation.

The ceramic glass resists very well at high

temperatures, but it is fragile, so avoid impacts

with it.

Product images are purely indicative