ITALIANO

ENGLISH

DEUTSCH

FRANÇAIS

ESPAÑOL

004778230 - 15/04/2020

33

6 OPERATION

6.1 Hydraulic system

The hydraulic system and the appliance itself must be connected by qualified personnel in compli-

ance with laws and regulations in force in the country (in Italy ref. D.M. 1/12/1975 and UNI 10412-2). The

hydraulic connection to the appliance must be made before the upper part of the casing and the

outer hood are installed.

1.

Before installing the casing, perform the hydraulic seal test on the pipes connected to the

appliance.

2.

Make sure that all control and safety devices, including those supplied as standard, have been

installed correctly.

Make sure that, when the stove is in use, all conditions allowing the system to absorb the

heat generated safely are in place.

MAIN CIRCUIT: OPEN CHAMBER

MAXIMUM SECONDARY CIRCUIT PRESSURE: 2.5 bar

DO NOT INCLUDE any room thermostats that stop or start the circulation pump in order

to regulate the temperature in rooms. For safety reasons, the pump must ALWAYS operate

for as long as the stove is burning fuel, to dispose of the heat generated in the Termopalex.

If the rooms are too hot, reduce the size of the fire, even letting it go out if necessary.

Never exceed the maximum recommended load of wood fuel indicated in the product booklet.

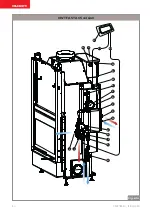

Description of the hydraulic connections

(Fig. 6.1a)

The hydraulic unit comprises the following parts:

A) Circulator (main circuit)

B) Circulator (secondary circuit)

C) Plate-type heat exchanger

D) Digital thermo-regulator

E) Main circuit delivery with cut-off valve

F) Manual secondary circuit vent

G) Expansion chamber open

H) Main circuit drain tap

I) Secondary circuit delivery with cut-off valve

J) Main circuit return cut-off valve

K) Secondary circuit safety valve (2.5 bar)

L) Secondary circuit filling/emptying

M) Probe well

N) Mains water inlet

O) Expansion chamber discharge

P) ACS mixing/delivery valve

Q) Top-up pipe connection

R) Main circuit top-up pipe

S) Secondary circuit return cut-off valve

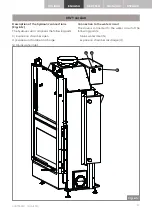

Connection to the water circuit

The stove is connected to the water circuit at the

following points:

• Hot water delivery to secondary circuit (I)

• Return from secondary circuit (J)

• Mains water inlet (N)

• ACS mixing/delivery valve (P)

• Expansion chamber discharge (O)

• Secondary circuit filling/emptying (L)

• Secondary circuit safety valve discharge (K)

• Appliance boiler discharge (H)

Probe connection

Connect the two probes of the temperature

controller (S1 and S2). Insert S1 in the housing

(M) on the fireplace. Place S2 on the secondary

return pipe, near the shut-off valve (S).

Digital temperature controller (ACS)

configuration

Set the digital temperature controller according

to “system diagram n°17”.

Set parameter A25 of the GLH 110 to 48°.

Follow the instructions in the temperature

controller manual.

HWT FAST ACS version

Summary of Contents for TERMOPALEX HWT

Page 21: ......

Page 32: ...32 004778230 15 04 2020 Fig 5 4i Fig 5 4j Fig 5 4k Fig 5 4l...

Page 36: ...36 004778230 15 04 2020 S1 S2 D C M E N F A O G L I H K B J S Fig 6 1b HWT FAST version...

Page 40: ......

Page 59: ......

Page 70: ...70 004778230 15 04 2020 Fig 5 4i Fig 5 4j Fig 5 4k Fig 5 4l...

Page 74: ...74 004778230 15 04 2020 S1 S2 D C M E N F A O G L I H K B J S Fig 6 1b version HWT FAST...

Page 78: ......

Page 97: ......

Page 98: ......

Page 99: ......