5

Chassis and Body Preparation

Revision 1.3

- 15 -

5

Chassis and Body Preparation

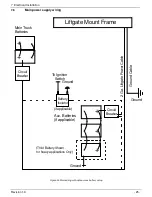

The ILP liftgate will require different mounting space requirements depending on floor heights.

1. Determine the correct frame cut out according to your specific bed height refer to Chapter

4.2 and 4.4.

2. With

long overhang

it is even more important to maintain

MIN F-Dim

and

MAX ground

clearance

.

3. Trim rear of truck frame per above picture.

5.1

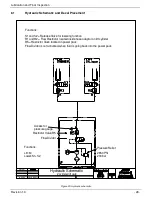

Bed Extension & Dock Bumper Installation

Tack Weld Or ClampTo Rear Sill

Tack or clamp channel to hold in place

Do NOT weld along vertical posts on van install.

3/16" welds for bed extension

Floor at Back & Front Edge

Bed Extension Must Be Flush With

Channel or Equiv.

3" Channel

"A"

Channels Shipped with 45° angle on each side

"A"

"A"

Bed Height Bumper

44" and Above

24"

43" and Below

20"

Note:

20" Bumpers Have Single Step

Interlift 12" Bumpers might

need notching in some cases

3/16"

3/16"

3/16"

12"

12"

Figure 10 Bed extension install

Figure 11 Dock bumper install

1. Tack weld channels or angle (2) to rear sill (not supplied) only temporarily, if possible use

clamps

2. Center bed extension, flush with floor. (

Figure 10

) .

3. Clamp or tack weld to channels or angle

4. Verify bed extension is

centered

on body and flush at the sides

5. Weld as shown in

Figure 12

from the top and the bottom

->

3/16” x 4” welds on approximately 10” centers alternate top and bottom welds

Figure 12 Bed extension weld areas

6. Install dock bumpers (if applicable) (available from

PALFINGER Liftgates

as an option)

7. If installing dock bumpers refer to Figure 9

Welds