ILSL 33/44 Owner‘s Manual

Rev.1.1

24

6.5

Quick Check List

1.

Operate the lift gate throughout its entire operation and check for noise and damage such as bent

parts or cracked welds.

2.

Inspect all welds and fasteners that attach the mount frame to the truck. All pins and bolts that

connect the lift arm to the mount frame and to the platform.

3.

Visually inspect the hydraulic lines for damage, scratches, bending or leakage.

4.

Inspect the cylinders for leakage and that the cylinder pins are secured with lock bolts.

5.

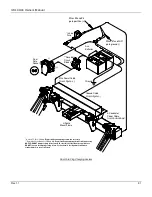

Check the oil level when the platform is down at ground level. The level should fall between the

upper markings 5 and 7 on the tank. We recommend replacing oil after the first 1200 cycles, after

that on a yearly basis in the fall before winter begins.

6.

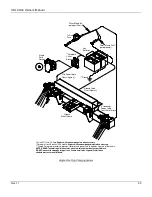

Check for oil leakage around the power pack and inside mount tube. Tighten or replace components

if needed. If you perform work on any hydraulic components bleed the air out of the system by

operating all functions several times.

7.

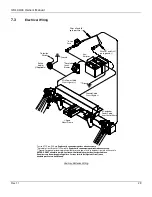

Check all electrical connections. Clean and protect battery terminals and check for tightness.

8.

Inspect all the terminals on the solenoid-operated valves at the port of the cylinder. Lubricate the

terminals for better protection from oxidation if needed.

9.

Grease all zerks on the lift gate and make sure they all take grease. Sometimes it helps to operate

the lift gate while you do this.

10.

Test all the lift gate functions.

11.

Check the function of the pressure relief valve.

12. When doing daily checks and you find any kind of damage that can make the use of the liftgate

dangerous, it must be repaired before using. All repairs should be made by an authorized technician.

Use only original spare parts. If in doubt contact your PALFINGER Liftgates distributor or call

PALFINGER Liftgates directly.

Do not cover up any accidents or damage; it can be dangerous for you and your co-workers.