ILSL 33/44 Owner‘s Manual

Rev.1.1

33

7.4

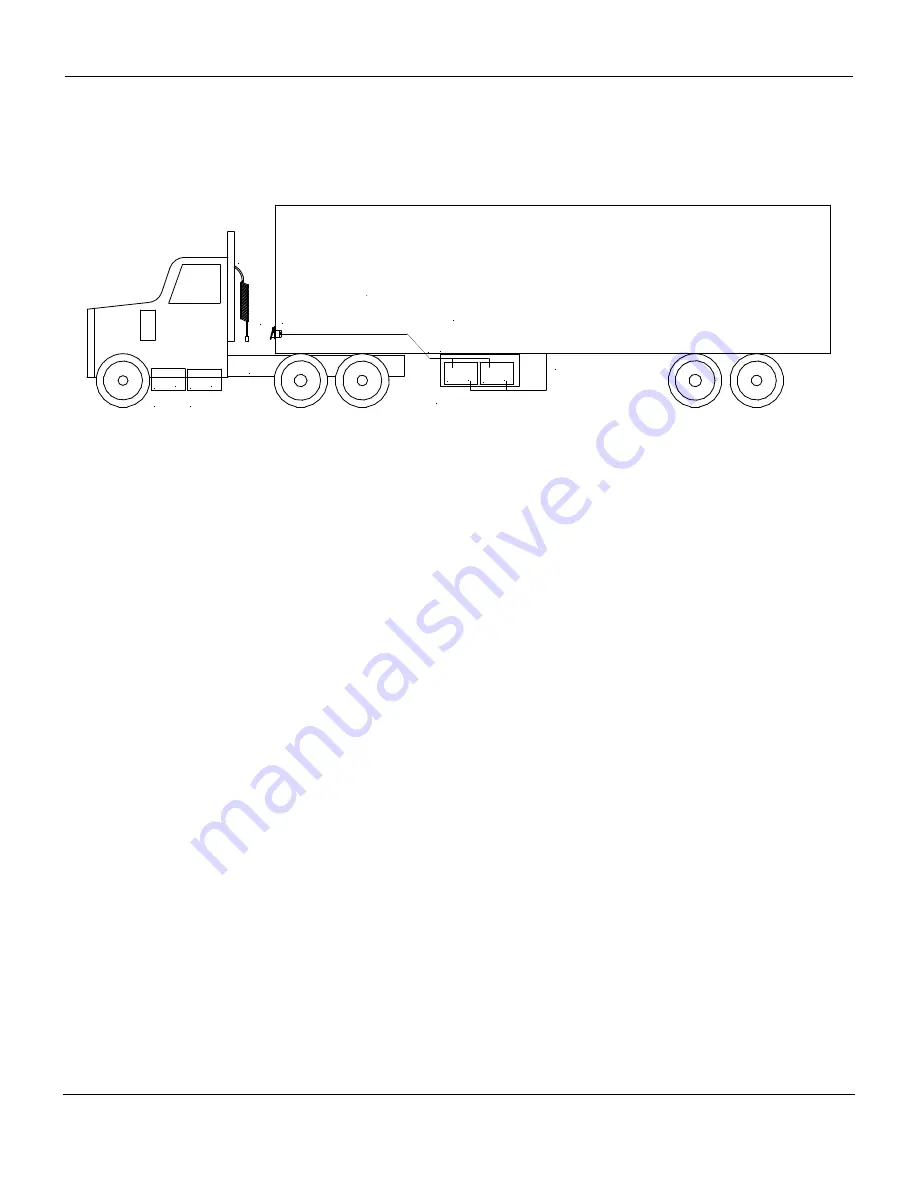

Cross Test on Single Pole Plug Charge System

Testing of full system using a battery load tester. Start with testing each individual battery on both tractor

and trailer before proceeding to check the system:

A. 12V lead from tractor coil cord

B. Center (+) plug on front of trailer

C. Trailer Ground on front of trailer

D. Tractor chassis ground

A

+ - + -

+ - + -

C

B

C

B

B

C

D

C

B

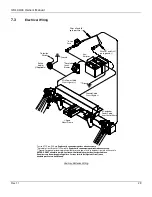

1. Tractor Test:

•

Ground battery load tester on tractor chassis point (D)

•

Connect positive load tester cable on positive pole of single pole plug at end of tractor coil

cord (A)

•

Run load test- This will test entire circuit on tractor including ground

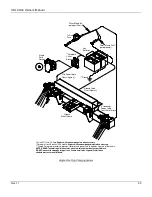

2. Trailer Test:

•

Ground battery load tester on trailer chassis point (C)

•

Connect positive cable on positive pole of single pole plug receptacle on trailer (B).

•

Run load test- This will test entire circuit on tractor including circuit breakers and ground

between trailer batteries and trailer chassis.

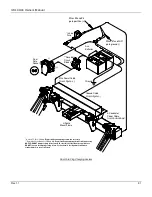

3. Tractor and Trailer Charging system test while connected:

•

Ground battery load tester on tractor chassis point (D)

•

Connect positive cable on positive pole of single pole plug receptacle on trailer (B).

•

Run load test- This will test entire circuit on tractor and trailer including ground between

tractor, trailer, and circuit breaker on trailer.

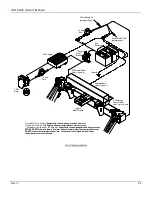

A simple low amp voltage test at the front of the trailer or at the tractor will not show insufficient connections

or ground problems.