Revision 1.1

26

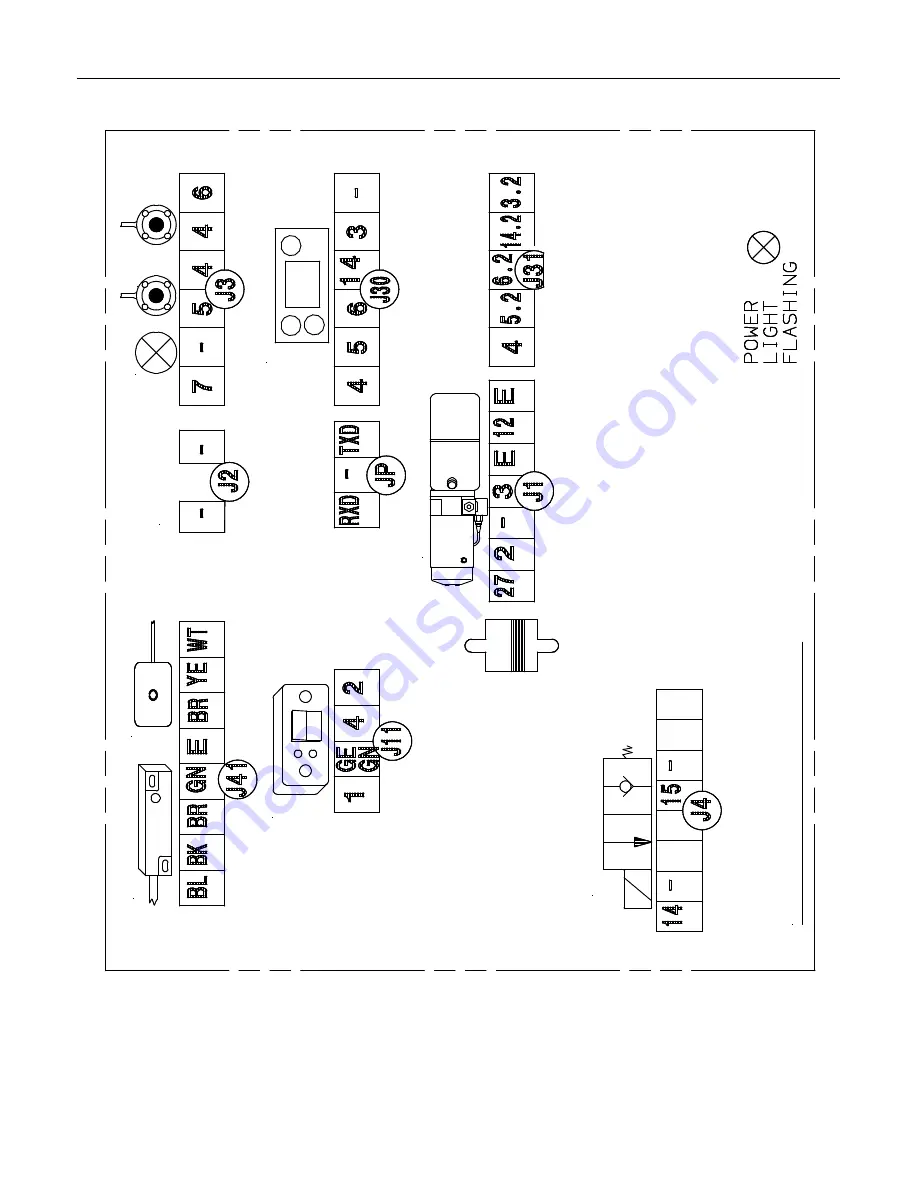

7.3.3

Connector Overview

C

IR

C

U

IT

B

O

A

R

D

P

O

W

E

R

P

A

C

K

B

-1

3

L

IF

T

A

R

M

B

-1

6

P

L

A

T

F

O

R

M

G

R

O

U

N

D

C

O

N

T

R

O

L

P

A

N

E

L

C

A

B

C

U

T

O

F

F

S

W

IT

C

H

F

O

O

T

C

O

N

T

R

O

L

W

A

R

N

IN

G

L

IG

H

T

S

C

Y

L

IN

D

E

R

S

L

IF

T

1

5

(

2

e

a

)

T

IL

T

1

4

(

2

e

a

)

Figure 9: Connector Overview

(1

e

a

)

(1

e

a

)

Summary of Contents for MiniFix

Page 14: ...Revision 1 1 11 ...