PTV 33/44/55/66

Owne

r’s Manual

Rev. 1.0

24

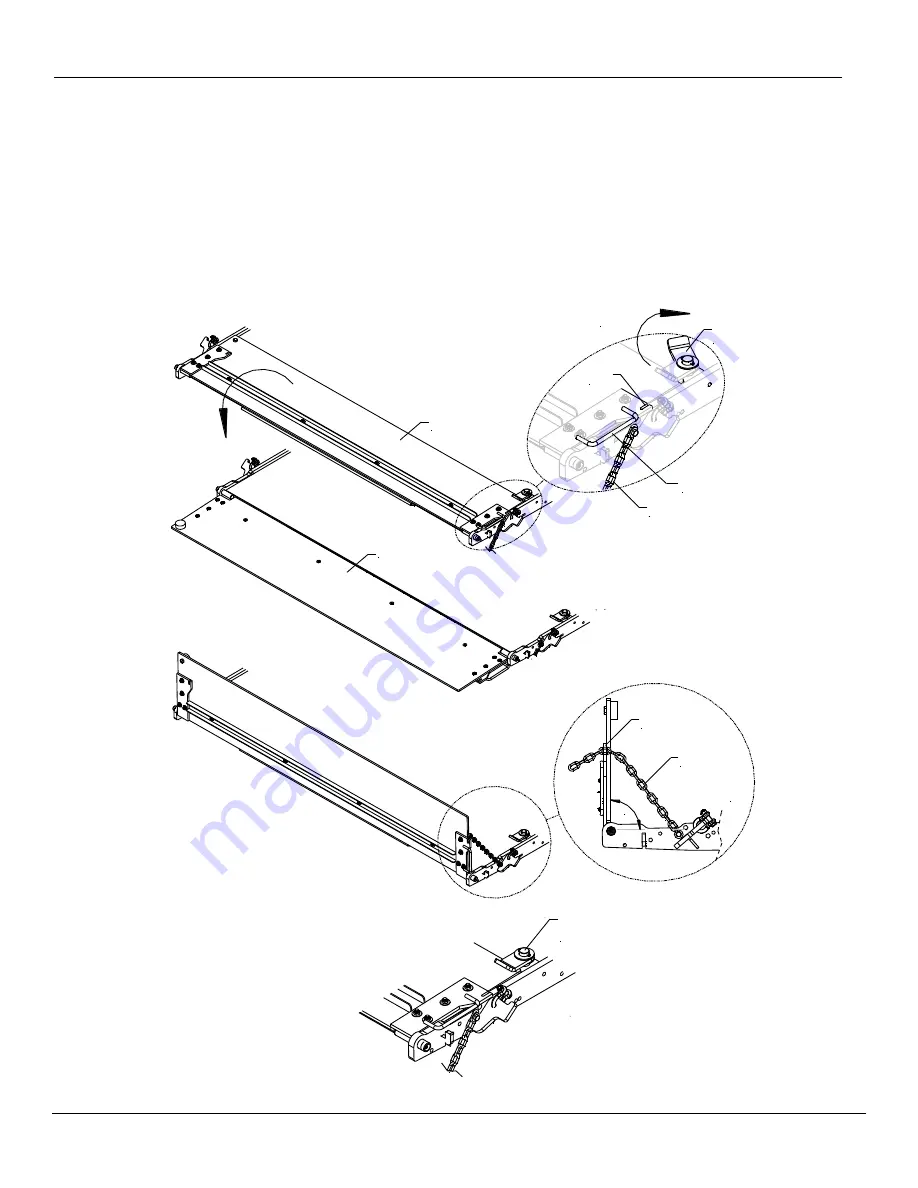

7.6

Aluminum Retention Ramp

1. Lower the platform to the ground. Turn the retainer latch clockwise to release the ramp. Use the ARR handle

on the side to open the retention ramp.

2. Load platform. To use the ramp as a load retention, stop, place the ramp 90° to the platform and use the

chain to secure the ramp.

3. Lower the platform down to the ground and remove the chain from the retaining notch. Place the ARR back

in its original position and turn the retainer latch enough to allow the ramp to lay between the platform and

retainer. Proceed to storing the platform.

Stored

ARR

ARR

Retainer

Latch

ARR

Chain

ARR

Handle

Turn

Clockwise

ARR

Chain

Chain

Notch

90°

Opened

ARR

ARR laying

between

platform and

retainer latch

Chain

Notch

Summary of Contents for PTV 35

Page 1: ...PTV OWNER S MANUAL 04 21 ...