PTV 35/44/55/66 Installation Manual

Rev. 1.1

71

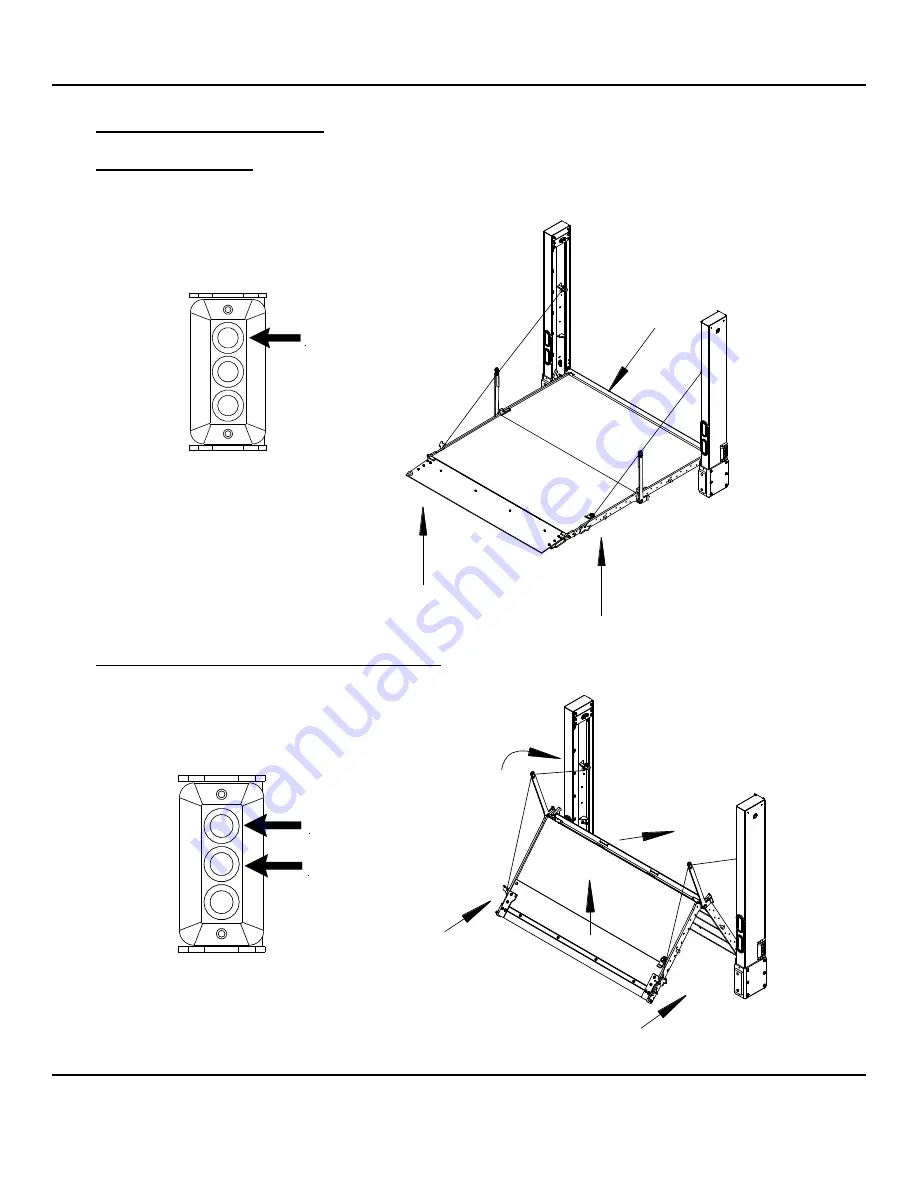

4. Raise the platform to bed level: Pu

shing the “UP” button, raise the platform to bed level.

5. Bleeding the system: With the platform at bed level, push the

“UP” button for thirty (30) seconds. This

will bypass hydraulic fluid through hydraulic poppet valves located in each of the lift cylinder pistons

returning hydraulic fluid back to the reservoir via the return lines.

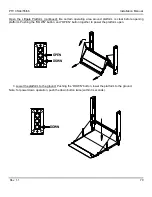

UP

6. Closing and Storing of the Platform for transit: With the platform open at bed level use the

“UP” button

and

“CLOSE” button together, power the platform closed.

UP

OPEN