UT319

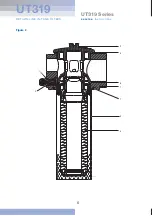

UT319 Series

R E T U R N L I N E I N - TA N K F I LT E R S

s e r v i c e

i n s t r u c t i o n s

Because of developments in technology these data or procedures may be subject to change.

Consequently we advise users to review their continuing validity annually.

Part numbers quoted above are protected by the Copyright of Pall Europe Limited.

and Pall are trade marks of Pall Corporation.

Filtration. Separation. Solution is a service mark of Pall Corporation.

©2008, Pall Europe Limited.

June 2008. Printed in England. IMSIUT319

Visit us on the web at www.pall.com

Pall Corporation has offices and plants throughout the world in locations including:

Argentina, Australia, Austria, Belgium, Brazil, Canada, China, France, Germany, Hong Kong,

India, Indonesia, Ireland, Italy, Japan, Korea, Malaysia, Mexico, the Netherlands, New Zealand,

Norway, Poland, Puerto Rico, Russia, Singapore, South Africa, Spain, Sweden, Switzerland,

Taiwan, Thailand, United Arab Emirates, United Kingdom, United States, and Venezuela.

Distributors are located in all major industrial areas of the world.

Pall Industrial Manufacturing

New York -

USA

+1 516 484 3600

telephone

+1 888 333 7255

toll free

+1 516 484 6247

fax

Pall Industrial Manufacturing

Portsmouth -

UK

+44 (0)23 9230 3303

telephone

+44 (0)23 9230 2507

fax