27

PALLMANN GmbH l Ein Unternehmen der Uzin Utz AG | Im Kreuz 6 | 97076 Würzburg | T49 931 27964-0 | T49 931 27964-50 I www.pallmann.net

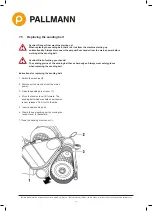

7. Loosen the locking screw on the trolley lever next to

the right-hand adjustable castor.

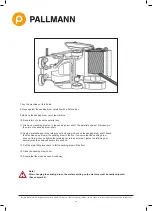

9. Tighten the locking screw on the landing gear lever

next to the right-hand roller.

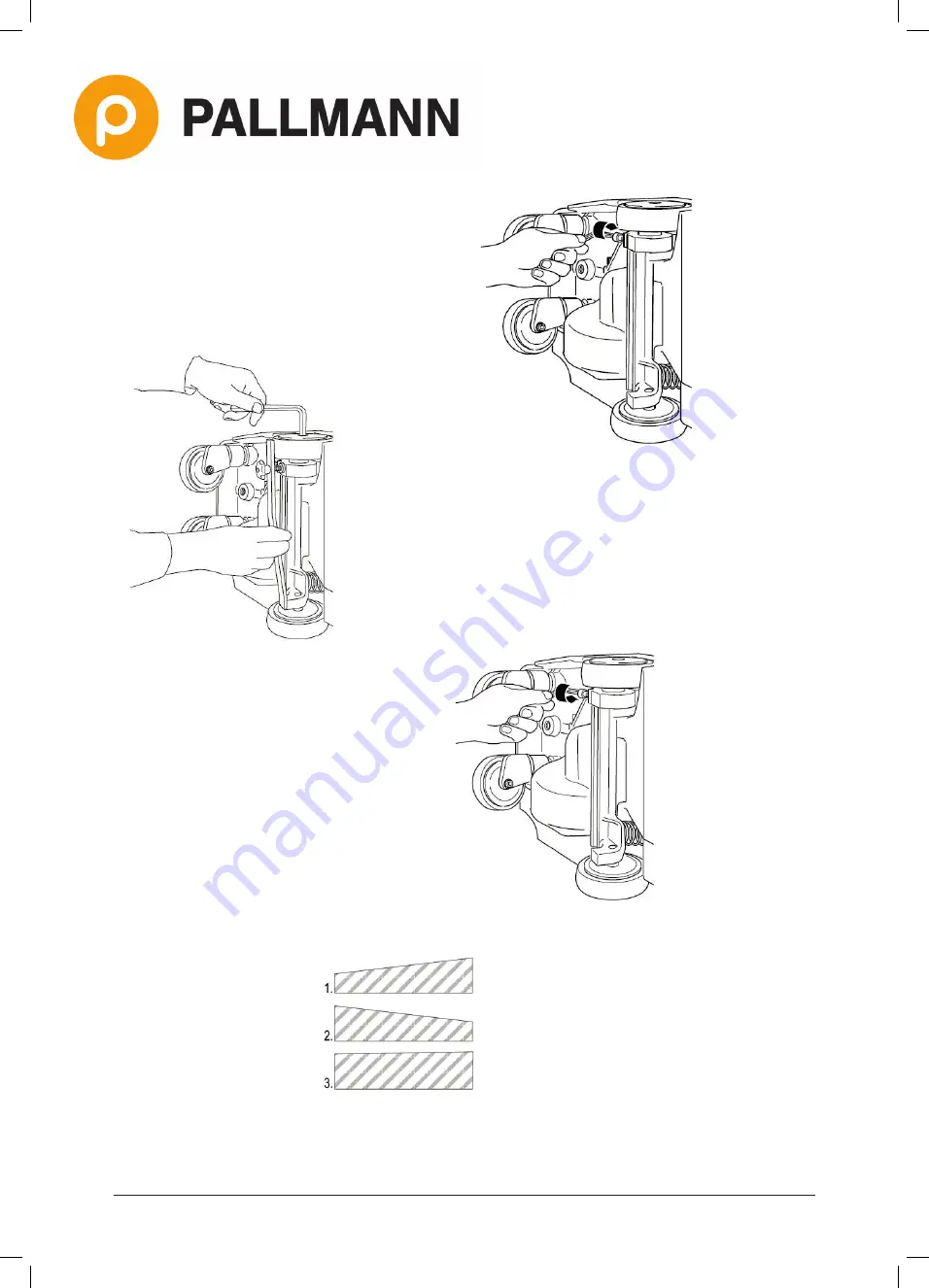

10. Check the grinding pattern.

1. readjustment required

2. readjustment required

3. optimal grinding pattern

8. Adjust the right-hand roller to the set dimension using the roller adjuster.

Turn the axle of the right-hand roller with the hexagon screwdriver until

the right-hand roller lightly touches the tongue of the roller adjuster.