Page 17 Gecko Star 2.0 01/2017

9.1 Tightening drive belt

Note!

Ensure that the drive belt is sufficiently pre-tensioned to prevent the occurrence of damage.

Check the pressure and the drive belt in constant intervalls.

Steps:

1. Switch the machine off.

2. Unplug the cord from the main power supply

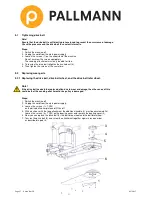

3. Loosen the screws (1) on the underside of the machine.

Do not unscrew the screws completely.

The sanding attachment must only be able to slide.

4. To tension the drive belt retighten the knurled nut (4).

5. Then tighten the screws at the same time.

9.2 Replacing wear parts

9.2.1 Replacing the drive belt, drive belt wheel, and the drive belt idler wheel.

Note!

If the drive belt needs to be replaced often due to wear or damage, then the cause of this

could be that the sanding attachment drive pulley is damaged.

Steps:

1. Switch the machine off.

2. Unplug the cord from the main power supply.

3. Loosen the screws (1 = TX20)

on the drive belt cover plate and lift this off.

4. With machines with the long attachment the additional handle (3) must be unscrewed first.

Loosen the screws (4 = TX30) on the bearing cover, and remove the bearing cover (5).

6. Now you can replace the drive belt (6), the belt drive wheel and the belt idler wheel.

7. Tension the drive belt (6) and screw the attachment together again in reverse order

as described in point 8.

3

4

5

6

1

Summary of Contents for GECKO STAR 2.0

Page 19: ...Page 19 Gecko Star 2 0 01 2017...