2

Palmgren Operating Manual & Parts List 9661052, 9661103, 9661202, 9661303, 9661402 & 9661501

DESCRIPTION

Palmgren Arbor Presses are designed for riveting, squeezing, bending,

punching, flattening, removing a bearing or pressing in bearings.

Removable, rotating, machined anvil has 4-slots to provide

convenient support for workpieces that vary in size and shape.

Presses are suited for work in production lines as well as in machine

shops, automotive repair shops and home workshops. Model

9661052 is a 0.5-ton press, 9661103 is a 1-ton press, 9661202 is a 2-ton

press, 9661303 is a 3-ton press, 9661402 is a 4-ton press and 9661501

is a 5-ton press.

SAFETY RULES

•

For best operation, the arbor press must be bolted to a stationary

object that is also affixed to the floor.

•

When using the press, be sure the work is mounted securely in it.

Do not attempt to use the press with the workpiece mounted on

an angle.

•

Use only accessories designed for the arbor press. Attachments

and equipment used in the pressing operation must be as strong

as the press. Use steel collars and blocks to press against the

workpiece.

•

Do not overload the press by using handle extensions (cheater

bars).

•

When not in use, the ram should be in the down position to

prevent accidents.

•

Know the arbor press and accessories. Read and understand

owner’s manual.

•

Wear a face shield or safety glasses.

•

Never place hands in jeopardy.

•

Always check your set up, i.e., see that the ram contacts

workpiece squarely before applying pressure.

•

Keep your mind on your work. Be alert.

•

Make sure workpiece, punch, anvil and accessories are securely

clamped.

•

Don’t force the arbor press or its accessories.

ASSEMBLY

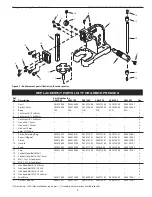

Refer to Figure 2.

•

Mount arbor press to bench or stand. Secure arbor press using

two mounting holes on the body (hardware is not supplied).

•

The 0.5, 1 and 2-Ton presses are completely assembled. The

handle needs to be installed on the 3, 4 and 5-Ton presses.

To install handle: Remove cap and bolt from handle (Ref. Nos. 12,

13 and 10). Insert handle into pinion (Ref. No. 9) and replace cap

and bolt. Secure handle in position with knob (Ref. No. 11).

•

To use with a punch: Remove pinion retaining ring and set screw

(Ref. Nos. 7 and 14) from pinion. Remove pinion from the body.

Remove ram (Ref. No. 8), mount ram upside down so the punch

hole is facing down. Replace pinion, pinion retaining ring and set

screw. Insert the punch best suited to the job. Magnet inside ram

will secure punch in position. Set screws (Ref. No. 4) will ease or

restrict the ram action. Adjust to your requirements.

MAINTENANCE

•

Oil the pinion periodically through the oil fitting, and grease the

ram rack whenever necessary. Keep a light film of oil on machined

surface to prevent rust. Keep work area clean. Clean the arbor

press of dirt and debris after every use.

•

If the ram is loose and drops by itself, loosen hex nuts and tighten

screws (Ref. Nos. 5 and 4) for adjustment. All screws should be

tightened with the same amount of pressure. Secure set screws

by tightening nuts.

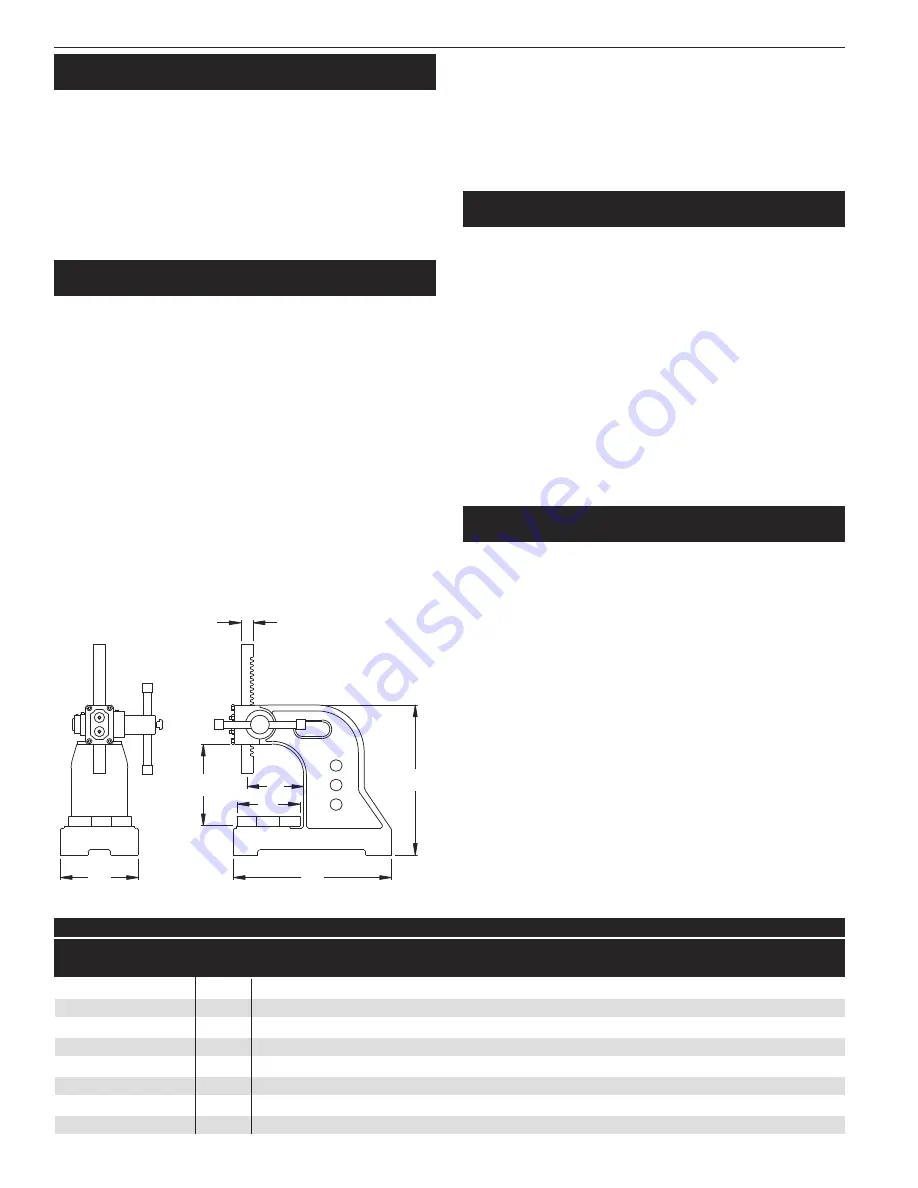

Base Length

Base Width

Height

Max. Work Height

Swing

Anvil Diameter

Ram Dimension

Ram Punch Hole

0.5-Ton

9661052

8.0"

4"

8"

4"

6.5"

3.25"

3/4" × 3/4"

3/8"

1-Ton

9661103

9.65“

5"

10"

5"

8"

4.25"

7/8" × 7/8"

3/8"

2-Ton

9661202

14"

7"

12"

6.5"

10"

6.5"

1" × 1"

1/2"

3-Ton

9661303

16"

7.5"

18"

11"

11.50”

6.5"

1.25" × 1.25"

1/2"

4-Ton

9661402

20"

10"

24"

14"

16.5"

10"

1.5“ × 1.5”

1/2"

5-Ton

9661501

24.5"

11"

31"

17.5"

18.50”

10.5"

2" × 2"

1/2"

L

W

H

A

2B

D

R × R

Model Size

Model Number

Dimension Specifications

A

W

L

B

D

H

R

Figure 1 - Dimensions