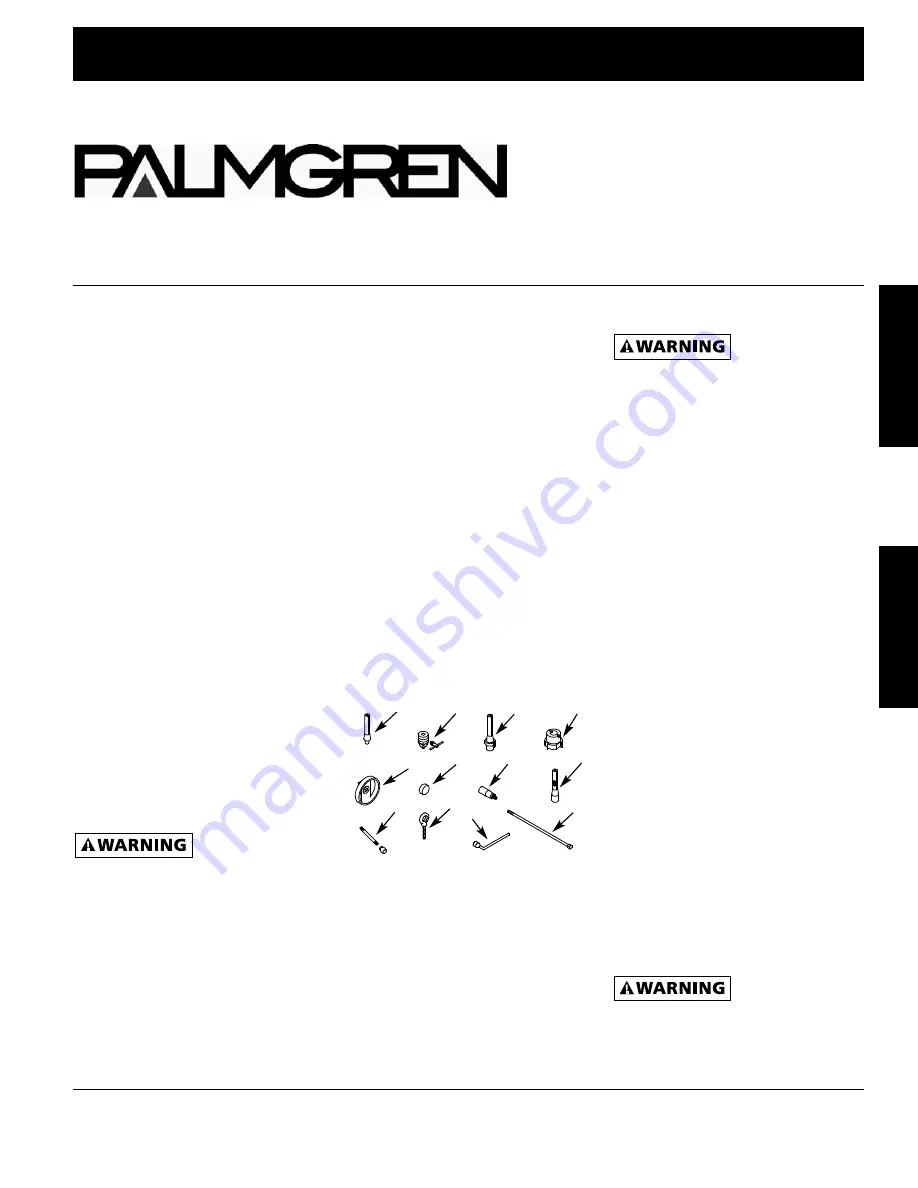

Unpacking

Refer to Figures 1 and 8.

Check for shipping damage. If damage

has occurred, a claim must be filed with

carrier immediately. Check for com-

pleteness. Immediately report missing

parts to dealer.

Carefully open crate and remove loose

parts box. Unbolt mill drill from ship-

ping pallet and remove from crate using

heavy duty lifting equipment such as an

overhead crane.

Eyebolts (Fig. 8, Ref. No. 46) are provided

to hoist machine. Insert the four eyebolts

into base (Fig. 8, Ref. No. 13) and secure

in position.

Be careful not to

touch overhead

power lines, piping, lighting, etc. if lift-

ing equipment is used. Mill Drill weighs

approximately 600 lbs. Proper tools,

equipment and qualified personnel

should be employed in all phases of

unpacking and installation.

Mill drill is shipped assembled except

for certain parts shipped loose in a

wooden box. Locate and account for

the following parts:

A Drill chuck arbor (on machine)

B 1/2” Drill chuck with key

C Face mill arbor

D 3” Face milling cutter

E Three Table handwheels

F Three Handwheel caps

G Four crank handles

H R8/MT3 Adapter

I

Three Quill handles and knobs

J

Four Eyebolts

K Wrench

L Drawbar (on machine)

6 pc. R8 collet set (not shown)

IMPORTANT:

Table is coated with a

protectant. To ensure proper fit and

operation, remove coating. Coating is

easily removed with mild solvents, such

as mineral spirits, and a soft cloth.

Avoid getting cleaning solution on

paint or any of the rubber or plastic

parts. Solvents may deteriorate theses

finishes. Use soap and water on paint,

plastic or rubber components. After

A

F

E

I

J

K

L

G

H

B

D

C

31664.00-1109

Mill Drill

Operating Instructions & Parts Manual

80161A

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Description

Palmgren 12-Speed Mill Drill Model 80161A is a ruggedly constructed machine pro-

viding accurate milling, drilling and boring capabilities. The fully enclosed R-8 spindle

has heavy-duty tapered thrust bearings at top and bottom of quill, adjustable depth

stop with scale, fine feed adjustment handwheel with .001” graduations and quill

lock down handle for securely clamping spindle at desired depth. One piece cast iron

head rotates 360° and travels vertically by rack and pinion.

Hinged pulley cover allows fast and easy speed changes. Large 32

3

⁄

8

x 9

1

⁄

2

” table has

dovetail ways with adjustable gibs and bronze lead screw nuts for accurate and rigid

table positioning. Table has four 5/8” T-slots, zero-setting handwheel dials with

.001” graduations, adjustable stops for longitudinal feed and cross feed way cover.

A 1½ HP, 1725 RPM, 115/230 volt, 60 Hz single-phase motor and 115v work lamp

are included. Prewired for 230v.

cleaning, cover all exposed surfaces with

a light coating of oil.

Never use highly

volatile solvents.

Non-flammable solvents are recom-

mended to avoid possible fire hazard.

Specifications

MODEL 80161A

Horsepower . . . . . . . . . . . . . . . . . . 1

1

/

2

HP

12 Speeds. . . . . . 150, 225, 255, 350, 400

500, 850, 1200, 1500,1600

2300, 3000 RPM

Table size . . . . . . . . . . . . . . . . 32

3

/

8

x 9

1

/

2

”

T-slots . . . . . . . . . . . . . . . 5/8” slots, four

Swing . . . . . . . . . . . . . . . . . . . . . . . . . 16”

Spindle taper . . . . . . . . . . . . . . . R-8 with

7/16”-20 drawbar

Drilling capacity. . . . . . . . 1

1

/

4

” mild steel

1

1

/

2

” cast iron

End mill capacity . . . . . . . 3/4” mild steel

Face mill capacity . . . . . . . . 3” mild steel

Spindle stroke . . . . . . . . . . . . . . . . . . . 5”

Max. distance spindle to table . . . . . 17”

Head swivel . . . . . . . . . . . . . . . . . . . 360°

Quill diameter . . . . . . . . . . . . . . . . . . . 3”

Quill collar diameter. . . . . . 3

3

/

4

” (96mm)

Column diameter . . . . . . . . . . . . . . . 4

1

/

2

”

Left-right table travel

(longitudinal). . . . . . . . . . . . . . . . . . . 23”

Front-back table travel (cross) . . . . . . 7”

Motor . . . . . . . . . . . . . 1

1

/

2

HP, 1725 RPM,

115/230 volt, 23/11.5 amp,

60 Hz, single-phase

Weight . . . . . . . . . . . . . . . . . . . . . 600 lbs

Shipping weight . . . . . . . . . . . . . 666 lbs

For your own safety,

read all of the

instructions and precautions before

operating tool.

E

N

G

L

I

S

H

E

S

P

A

Ñ

O

L

Figure 1 – Unpacking