Operation (Continued)

Loosen handle and push motor mount

plate away from head to tension rear

V-belt. Tighten handle. Check belt ten-

sion and adjust if necessary. Close pulley

cover.

Secure pulley cover latches.

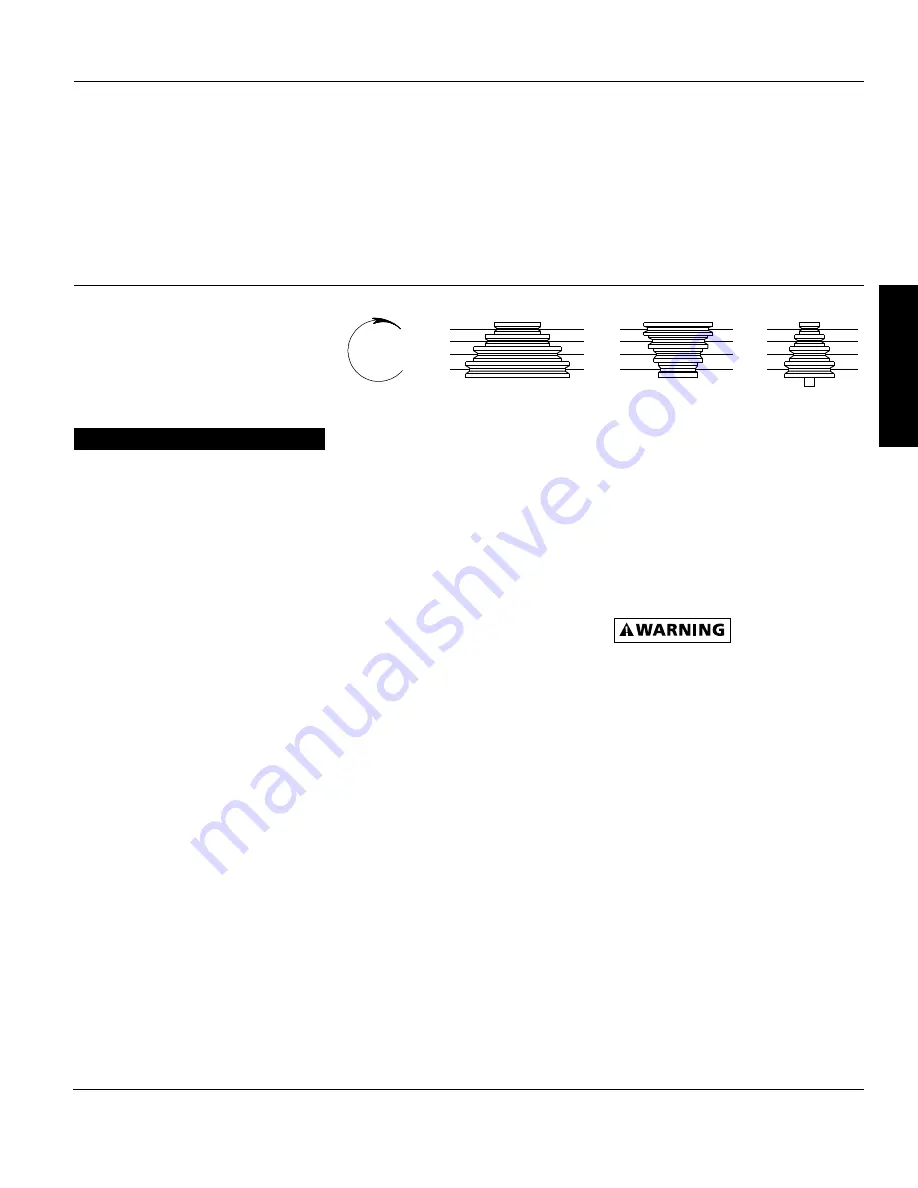

Spindle RPM

Belt Location

150

A1-4Z

225

B2-4Z

255

A1-3Y

350

C3-4Z

400

B2-3Y

500

A1-2X

850

D4-3Y

1200

C3-2X

1500

B2-1W

1600

D4-2X

2300

C3-1W

3000

D4-1W

SPINDLE OPERATION

Refer to Figures 6 and 7, pages 8 and 10.

Palmgren mill drill is equipped with

spindle fine feed handwheel and spin-

dle depth lockdown handle.

Engage fine feed handwheel (Fig. 6,

Ref. No. 36) by rotating pinion knob

clockwise (Fig. 6, Ref. No. 39) until tight.

Disengage fine feed by loosening pin-

ion knob.

Spindle depth can be locked into position

by tightening quill lock handle (Fig. 7,

Ref. No. 56). Bring spindle down to

desired position and tighten quill lock

handle to hold spindle position.

DEPTH STOP

Refer to Figures 6 and 7, pages 8 and 10.

Repeated operations where depth of cut

is consistent are made easier by using

depth scale (Fig. 6, Ref. No. 44) and

depth setting knob (Fig. 7, Ref. No. 61).

Depth of cut is shown on depth scale

and indicated by depth indicator

(Fig. 6, Ref. No. 45).

Depth of cut is set by rotating depth

setting knob until desired depth is

obtained.

HANDWHEEL SCALES

Refer to Figure 8, page 12.

The cross feed handwheel and right-

hand longitudinal handwheel are

equipped with graduated collars.

One full rotation of handwheel moves

table .100”. Handwheel scales are grad-

uated in .001”.

Scales are used when precise movement

of table is required.

Scales can be zeroed by loosening dial

screw (Ref. No. 5) and rotating lead

screw dial (Ref. No. 4) until zero marks

are aligned.

Tighten dial screw.

TABLE STOP BLOCKS

Refer to Figure 8, page 12.

Longitudinal travel can be limited to

make repeated operations easier by

using the table stop blocks (Ref. No. 27).

Table stop blocks are positioned to con-

tact table stop bracket (Ref. No. 21) lim-

iting table travel.

Adjust stop blocks by loosening socket

head bolts (Ref. No. 26) and moving

stop blocks to desired position. Secure

socket head bolts.

TABLE LOCKS

Refer to Figure 8, page 12.

Mill drill table can be locked into position

using table lock handles (Ref. Nos. 32 and

41).

Longitudinal position is secured by tight-

ening lock handles on front of saddle.

Cross feed position is secured by tighten-

ing lock handles on right side of saddle.

REMOVE ARBOR

Be sure mill drill is

turned off and is dis-

connected from power source before

removing arbor.

1. Loosen draw bar with one or two

turns.

2. Tap draw bar top with mallet to free

arbor.

3. Loosen drawbar completely until

arbor drops from spindle..

OPERATING CONTROLS

Refer to Figure 7, page 10.

Power lamp (Ref. No. 64)–This lamp will

be illuminated when the machine is

connected to power source.

Emergency stop switch

(Ref. No. 65) – Press to stop machine.

The switch must be twisted clockwise

until it pops outward in order for the

machine to be operable.

Start Switch (Ref. No. 67) – Press to start

machine.

Stop Switch (Ref. No. 68) – Press to stop

machine during normal operation.

Model 80161A

5

Palmgren Operating Instructions and Parts Manual

Figure 4 – Spindle Speed Chart

B

C

A

1

2

3

4

Motor

Spindle

Spindle

Rotation

D

X

Y

W

Z

E

N

G

L

I

S

H