3

SAFETY RULES (CONTINUED)

TOOL SHOULD BE MAINTAINED

•

Always unplug tool prior to inspection.

•

Read operating instructions manual for specific maintaining

and adjusting procedures.

•

Keep tool lubricated.

•

Use sharp cutters and keep the tool clean for safest operation.

•

Remove adjusting tools. Form the habit of checking that adjust-

ing tools are removed before turning on the machine.

•

Keep all parts in working order. Check to determine that the

guard or other parts will operate properly and perform their

intended function.

•

Check for damaged parts. Check for alignment of moving parts,

binding, breakage, mounting and any other condition that may

affect a tool’s operation.

•

Damaged parts should be properly repaired or replaced. Do not

perform makeshift repairs. (Use the parts list provided to order

replacement parts.)

KNOW HOW TO USE TOOL

•

Use the right tool for the job. Do not force tool or attachment

to do a job for which it was not designed.

•

Disconnect tool when changing accessories such as bits, cut-

ters and the like.

•

Avoid accidental start-up. Make sure switch is in OFF position

before plugging in.

•

Do not force tool. It will work most efficiently at the rate for

which it was designed.

•

Handle workpiece correctly. Secure work with clamps or vise.

Leave hands free to operate machine, Protect hands from

possible injury.

•

Never leave a tool running unattended. Turn the power off and

do not leave tool until it comes to a complete stop.

•

Do not overreach. Keep proper footing and balance.

•

Never stand on tool. Serious injury could occur if tool is tipped

or if cutter is unintentionally contacted.

•

Keep hands away from moving parts and cutting surfaces.

•

Know your tool. Learn its operation, application and specific

limitations.

•

Feed work into a bit or cutter against the direction of rotation

of bit or cutter.

•

Turn the machine off if it jams. A cutter jams when it digs too

deeply into the workpiece. (The motor force keeps it stuck in

workpiece.)

•

Use recommended accessories. Refer to page 9. Use of improp-

er accessories may cause risk of injury to persons.

•

Clamp workpiece or brace against column to prevent rotation.

•

Use recommended speed for drill accessory and workpiece

material.

WARNING:

Think Safety! Safety is a combination of operator com-

mon sense and alertness at all times when drill press is being used.

ASSEMBLY

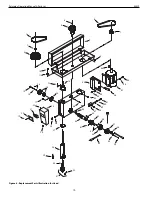

MOUNT DRILL CHUCK AND ARBOR

Refer to Figure 5.

•

Be sure spindle taper, arbor taper and chuck taper are clean

and dry.

•

Insert arbor into spindle, push arbor into spindle and twist

arbor slightly to release air trapped in taper. Make sure tang of

arbor seats properly into spindle.

•

Mount chuck onto arbor, push chuck over arbor and twist

chuck slightly to release air trapped in taper.

•

Place a block of wood on table, below chuck, and firmly pull

quill feed handle to securely seat chuck and arbor into spindle.

INSTALLATION

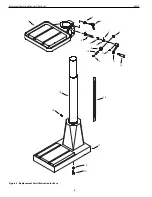

Refer to Figures 1, 2 and 3.

MOUNT DRILL PRESS

•

Drill press must be mounted to flat level surface. Use shims or

machine mounts if necessary. Do not mount drill press in direct

sunlight.

•

Be sure to bolt drill press to floor or bench securely to prevent

tipping and minimize vibration.

•

Tighten all nuts and bolts that may have loosened during

shipment.

POWER SOURCE

Drill press requires a 115/230 volt, 60 Hz power source.

To use the drill press with a 230V power supply, have a qualified

electrician attach a 230 volt, 20/30A three-prong plug onto drill

press line cord.

The motor is designed for operation on the voltage an frequency

specified. Normal loads will be handled safely on voltages not

more than 10% above or below the specified voltage.

Running the unit on voltages which are not within the range may

cause overheating and motor burn out. Heavy loads require that the

voltage at motor terminals be no less than the voltage specified.

GROUNDING INSTRUCTIONS

WARNING:

Improper connection of equipment grounding con-

ductor can result in the risk of electrical shock. Equipment should

be grounded while in use to protect operator from electrical

shock.

Check with a qualified electrician if grounding instructions are not

understood or if in doubt as to whether the tool is properly

grounded.

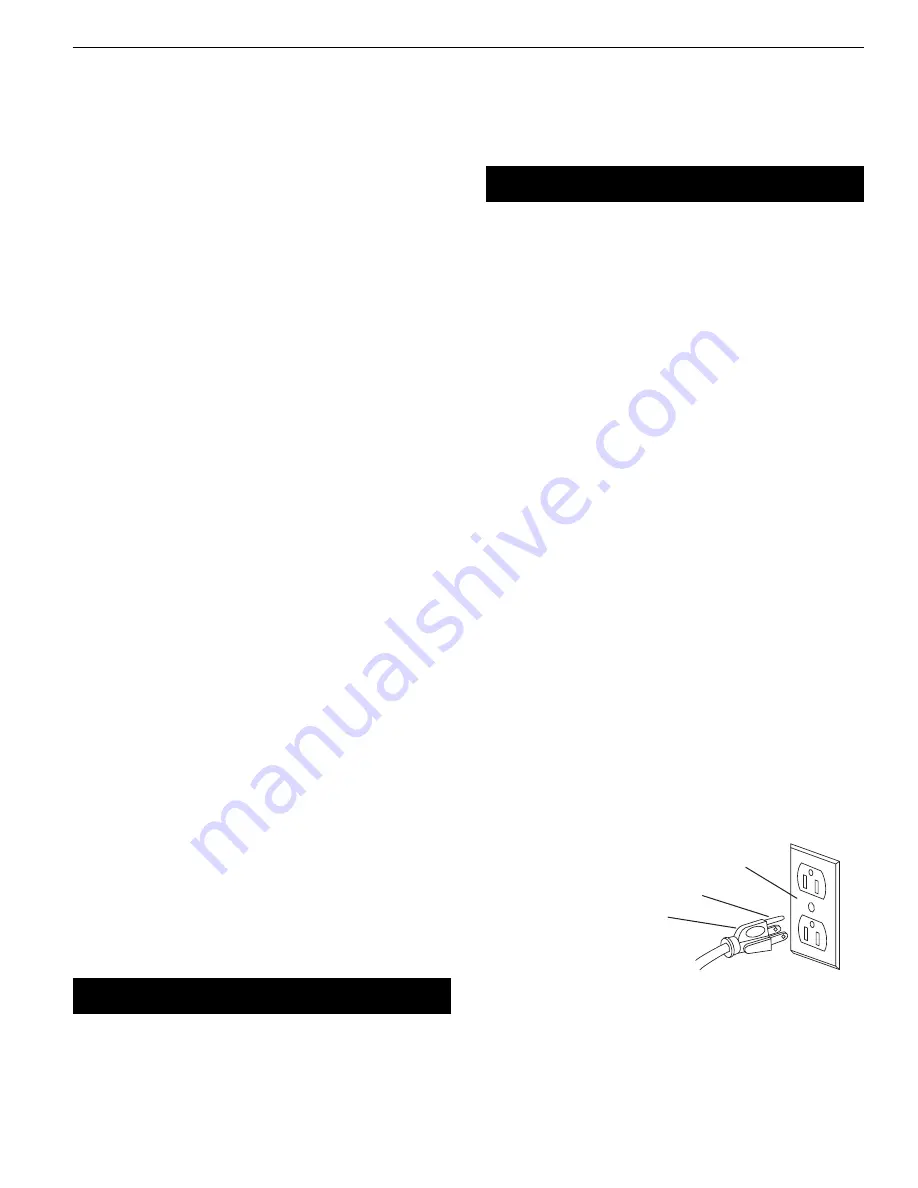

This tool is equipped with an approved 3-conductor cord rated up

to 300V and a 3-prong grounding type plug rated at 115V (See

Figure 1) for your protection against shock hazards.

Grounding plug should be plugged directly into a properly

installed and grounded 3-prong grounding-type receptacle, as

shown (Figure 1).

Do not remove or alter grounding prong in any manner. In the

event of a malfunction or breakdown, grounding provides a path

of least resistance for electrical shock.

WARNING:

Do not permit fingers to touch the terminals of plug

when installing or removing from outlet.

Plug must be plugged into matching outlet that is properly

installed and grounded in accordance with all local codes and

ordinances. Do not modify plug provided. If it will not fit in outlet,

have proper outlet installed by a qualified electrician.

Palmgren Operating Manual & Parts List

80329

Figure 1 – 3-Prong Receptacle

Properly Grounded Outlet

Grounding Prong

3-Prong Plug