10

Palmgren Operating Manual & Parts List

84315

OPERATION (CONTINUED)

Three different chisel contact points are shown in Figure 27B. It will

be noted that when a chisel is above the workpiece center (or

below it) the work surface sweeps past the chisel edge at an angle

and tends to carry the chisel in one direction or the other along

the rest.

•

Only when the chisel contacts the work on the centerline, does

the work surface pass squarely under the chisel edge. This,

then, is the position in which it is easiest to hold the chisel

steady. To obtain this position, place the rest approximately

1

/

8

″

(thickness of chisel) below center.

USING THE GOUGE

Three gouges, the

1

/

4

,

1

/

2

and

3

/

4

″

sizes, are adequate for general

homeshop turning. Other sizes from

1

/

8

to 2

″

can be purchased to

provide more flexibility.

The chief use of the gouge is for rough circumference cutting of

raw stock down to a cylinder of working size. It is best to use this

tool for rapid cutting away of large areas of the workpiece. When

the tool is used this way, it does not produce a smooth surface.

With practice, the gouge can be used for cutting coves and the

shaping of long cuts.

•

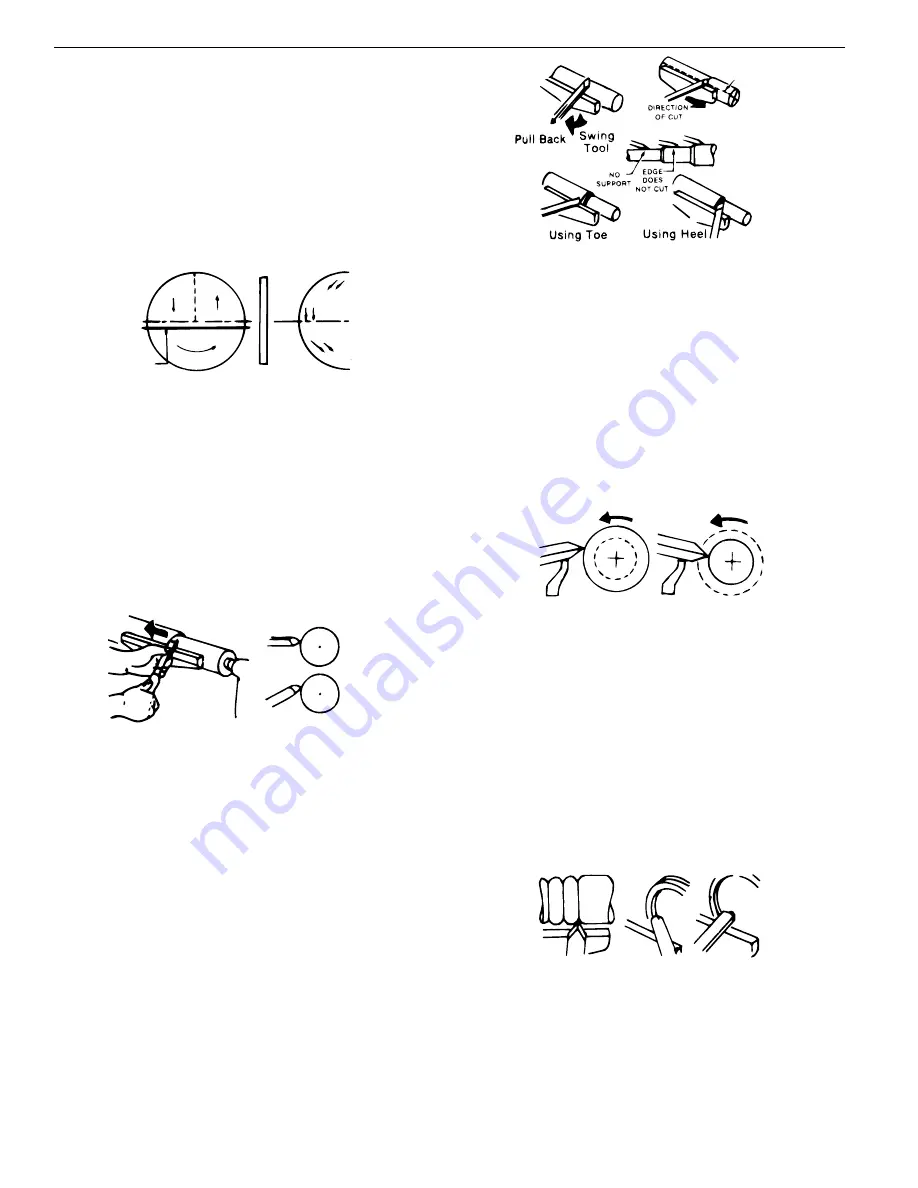

When used for cutting, the gouge is always held with the con-

vex side down. It should be rolled approximately 30° to 45° in

the direction in which it is being advanced along the rest and

the cutting edge should be slightly ahead of the handle.

USING THE SKEW

•

Two skews, the

1

/

2

and 1

″

sizes, are all that are needed for gen-

eral use. Other sizes are available.

This tool is nearly always used to make finished cuts, to cut vees

and beads, and to square shoulders. Properly used, it produces the

best finish that can be obtained with a chisel. It is not recommend-

ed for scraping because the edge tends to dull more quickly.

•

For finish cutting, the skew is held with the cutting edge con-

siderably in advance of the handle, bevel side down. Keep the

base of the bevel against the work. It is good practice is to

place the skew well over the work, pull it back until the edge

begins to cut, then swing the handle into position to advance

the cut.

Both the toe and the heel of the skew can be used for taking light

cuts, but do not penetrate the wood too deeply without cutting

clearances. There is danger of burning the tip of the tool.

USING THE PARTING TOOL

The parting tool has just one primary purpose: to cut into the

workpiece as deeply as desired, or all the way through to make a

cut-off. It is, therefore, a very narrow tool (

1

/

8

″

wide) and shaped to

cut its own clearance so that the edge will not be burned. When

used for scraping, however, the parting tool should be backed off

regularly to prevent overheating.

Unlike the gouge and skew, the parting tool is seldom held with

the bevel against the work. Since the amount of stock removal is

small, a support for the bevel is not necessary.

The tool is simply fed into the work at an angle (for cutting), or

pointed at the workpiece center (for scraping). It can be held easily

in one hand.

USING THE SCRAPING CHISELS

•

A

1

/

2

″

wide spear point chisel, a

1

/

2

″

wide round nose chisel, and

a 1

″

wide flat nose chisel complete the list of tools ordinarily

used by craftsmen and hobbyists.

Each of these scraping chisels can be purchased in various other

sizes for special purposes. All are very useful for diameter scraping

operations and for circumference scraping when cutting methods

cannot be employed.

•

The spear point is used for fine scraping and delicate opera-

tions such as the forming of beads, parallel grooves and shal-

low vees.

•

Edges and bowl contours can be rounded with the round nose

chisel.

•

Any flat surface can be scraped with the flat nose chisel.

USING SHAPER OR MOULDING KNIVES

•

An old chisel can be made to serve as a holder for shaper or

moulding knives.

Figure 27

Fig. 27A

Fig. 27B

Rest

Figure 28

Cutting Edge

Advanced

Wrong

Right

Figure 29

Figure 30

Cutting

Scraping

Figure 31

Spear

Point

Round

Nose

Flat nose