11

GETTING STARTED

SAFETY / SPECIFICATIONS

ASSEMBLY / INSTALLATION

OPERATION

TROUBLESHOOTING

MAINTENANCE / REPAIR

4. Do not force the workpiece into the sanding disc. Sand using

light pressure, letting the sanding abrasives time to do their

work!

5. Move your work piece slightly left and right on the disc,

keeping to the left-of-center, downward side. This will help

prevent resin or debris from building up on one area of the

disc, and also helps to prevent burning of the sanded surface

from excessive abrasive-action heat build-up.

Belt sanding

Dusty work environments may be

hazardous to your health. Always wear a

OSHA/NIOSH approved, properly fitting face mask or

respirator.

Always wear safety glasses complying

with U.S. ANSI Z87.1 before beginning any

sanding operation.

Make sure all disc guards are in securely

in place before starting the disc sanding

machine. Never operate the machine without the guards.

Always ensure the sander is turned off

and unplugged prior to attempting any

assembly, installation or changing of parts and accessories.

NOTE:

It is strongly recommended that users employ a

dust-collection system when using this machine. Use of

a dust mask or respirator is still required, even when

using a dust collection system.

1. Depending on what type of sanding that you will be doing,

set the Sanding Belt Table to the proper angle from 45° to

90° with a protractor, or other angle measuring tool or pre-cut

sample.

2. Once the table has been set for the correct sanding angle,

and all fasteners and handles are secure, the machine can

turned on.

3. Use the Miter Gauge for added control of the work piece

during sanding. The miter gauge can also be set to various

degree angles for maintaining accurate angles when sanding

small or multiple parts.

4. Do not force the work piece into the sanding belt. Sand using

light pressure, letting the sanding abrasives time to do their

work!

5. Move your work piece slightly left and right on the belt. This

will help prevent resin or debris from building up on one area

of the belt, and also helps to prevent burning of the sanded

surface from excessive abrasive-action heat build-up.

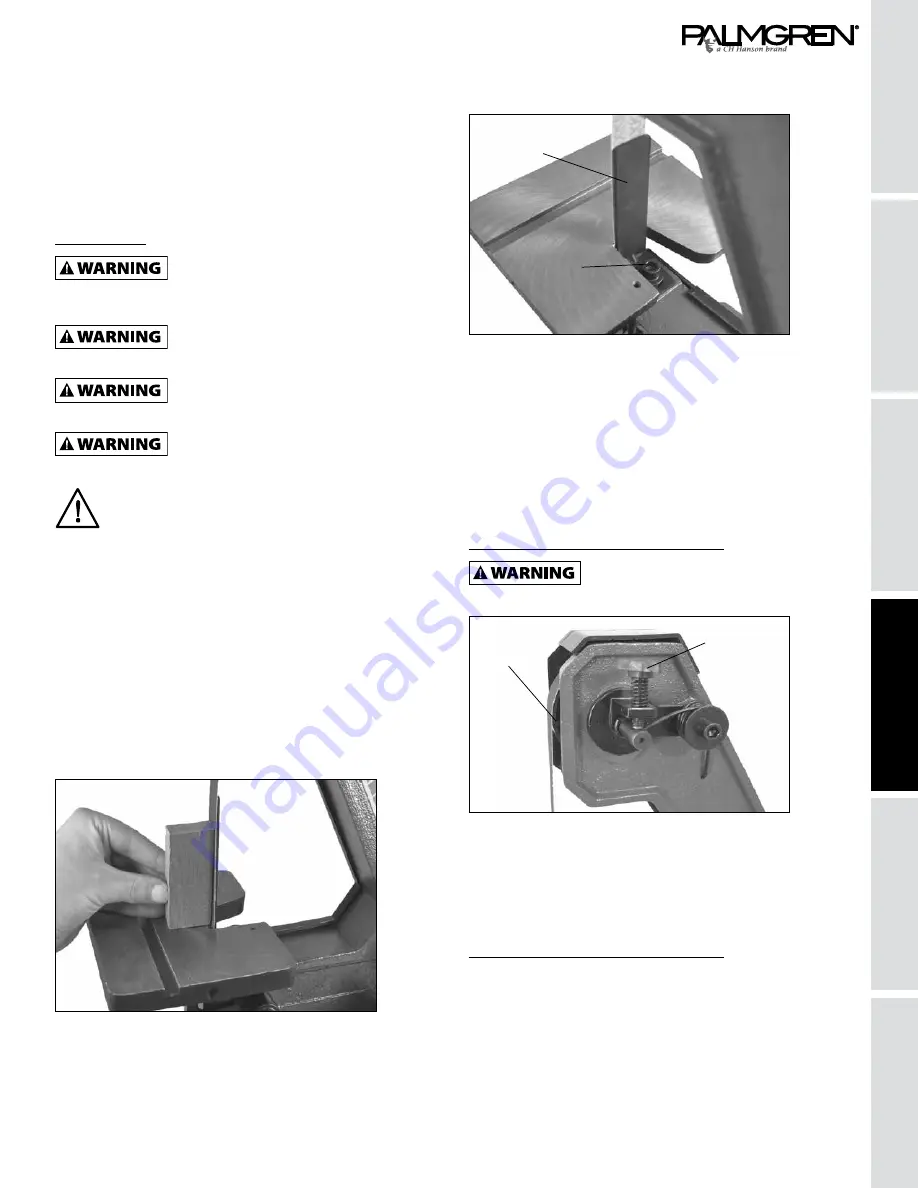

Platen

adjustment

hex screw

Platen

Figure 17

6. The Platen (#67) supports the back of the sanding belt and

offers a flat surface to sand or sharpen against. It should be

positioned so it is almost touching the back of the sanding

belt.

7. To adjust the platen, loosen the hex Screw (#7) at the rear of

the platen as shown in figure 17.

8. The platen can also be removed for contour sanding or

polishing.

Adjusting the sanding belt tracking

Always ensure the sander is turned off

and unplugged prior to attempting any

making any adjustments.

Tracking

adjustment

knob

Drive

wheel

1. Belt tracking on the center of the drive wheels is pre-set at

the factory. If an adjustment needs to be made, the sander

must be turned on.

2. Slowly turn the Belt Tracking Knob (#61) to correct the

tracking of the belt - left or right as needed - so that the belt

finally rides on the center of the guide wheel (#72).

Adjusting the sanding belt tracking

1. Remove the plastic Cover (#74) from the frame by

unscrewing the two knobs (#75).

2. Tilt the sanding belt table forward to 45° so that there is

ample space between the platen and rear of the table to

remove the belt.