9

GETTING STARTED

SAFETY / SPECIFICATIONS

OPERATION

TROUBLESHOOTING

MAINTENANCE / REPAIR

ASSEMBLY / INSTALLATION

NOTE:

It is easier to thread the bolt part of the handle

on first, then attach the handle to it using the spring

loaded Allen head cap screw provided.

Angle scale

and pointer

Figure 11

23. Attach the Angle Scale Pointer (#16) to the sanding disc

frame with the M4 Phillips pan head Screw (#14). The pre-

drilled hole is located just below the angle gauge. As shown

above in figure 11.

Figure 12

Adjust the pointer after the table is set to 90°, see page 12.

The disc table will tilt from 45° to 90°. As shown above in

figure 12.

Install the belt sanding table

Tables should be adjusted to a distance of

about 1/16” away from the sanding disc or

belt to prevent accidents if work or your fingers get stuck in

the gap while the sander is running.

24. An adjustable Handle and Washer (#25, 26) are supplied to

hold the Sanding Belt Table (#79) in position on the Sanding

Frame (#64).

25. Position the sanding belt table around the belt, and so that

it’s lower bracket with the curved slot is in position with the

threaded hole in the frame.

Figure 13

26. Fasten the table in place. Thread the bolt portion of the

locking adjustable handle through the bracket’s slot and into

the threaded hole of the sanding frame as shown in figure 13.

The table will tilt from 45° to 90°.

NOTE:

See page 12 for additional information on

adjusting the sanding tables.

Install the tool holders

Wrench holder

Miter guage

holder

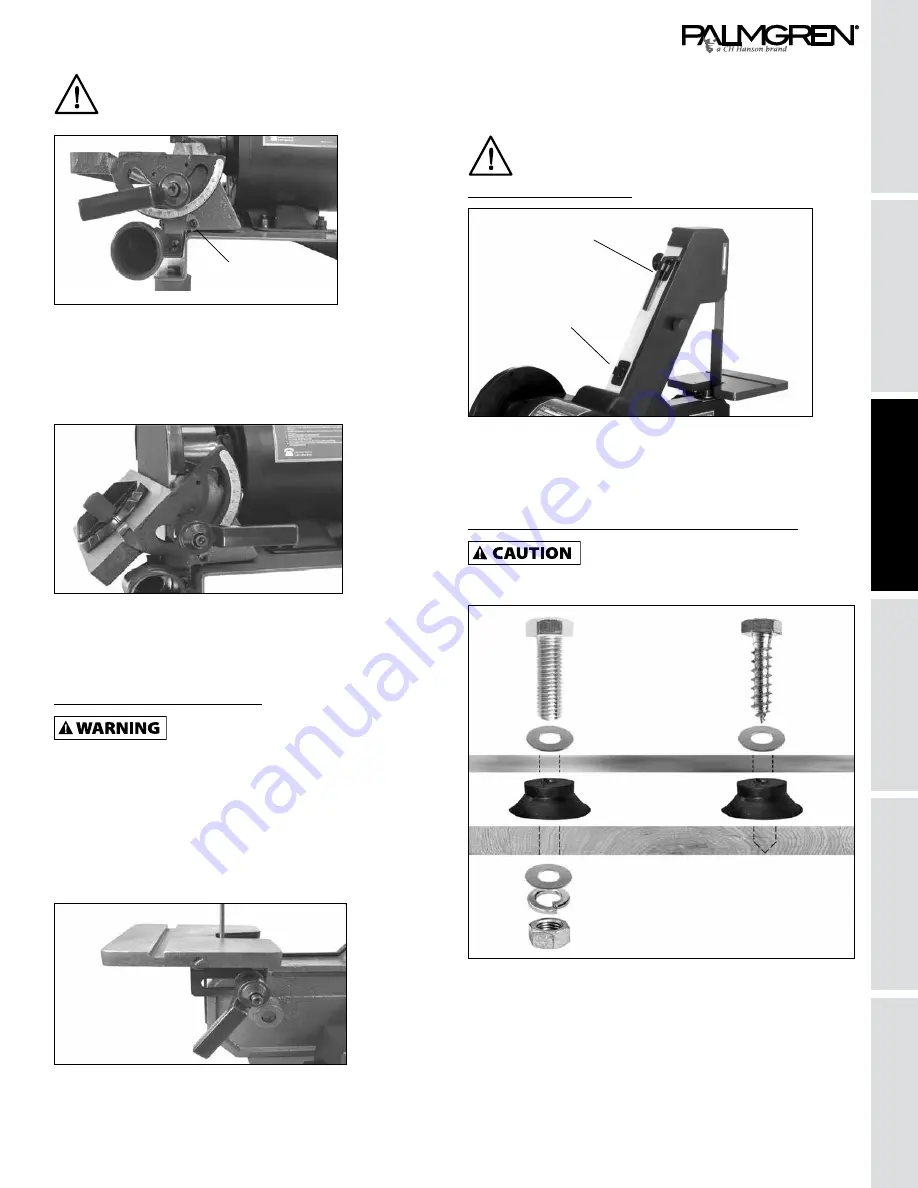

Figure 14

Holders (#88, 90) for convenient storage of the Miter Gauge and

Wrenches are supplied. Mount them onto the back of the Belt

Frame Casting (#64) with the Phillips Screws supplied (#89).

Mounting the sander to a workbench or stand

If during operation there is any tendency

for the sander to tip over, slide or walk on

the supporting surface, the sander must be properly

mounted to a workbench or stand.

Machine

bolt

Lag

screw

Washer

Rubber feet

Washer

Lock washer

Nut

Workbench

Figure 15

1. Rubber feet are fastened to this sander prior to shipping.

They may, or may not, be used when attaching the sander to

a bench or stand.

2. Position the sander on the workbench.