5

Palmgren Operating Manual & Parts List 9683295

OPERATION

• In the event of incorrect operation or dangerous conditions, the

machine may be stopped immediately by pressing the red

emergency shut off button on the operator control panel.

• The casual or voluntary opening of the flywheel covers causes a

safety switch activation that automatically stops all machine

functions. The flywheel cover doors MUST be closed tightly to de-

activate the safety switches.

• Check Coolant: Low coolant level can cause foaming and high

blade temperatures. Dirty or weak coolant can clog pump and

cause crooked cuts, low cutting rate and permanent blade failure.

Dirty coolant can cause the growth of bacteria with ensuing skin

irritation.

• Keep vise slides clean and oiled.

• Clean chips from blade wheels and areas around wheels.

• Saw Guide: Keep saw guide properly adjusted. Loose guide will

affect cutting accuracy.

• Saw Blade: Is saw blade sharp?

• Blade Speed: Is blade speed set correctly for workpiece material

and shape?

• Check Blade Tension: Particularly after initial cuts with a new

blade.

BLADE SELECTION

• Never use a blade so coarse that less than 3 consecutive teeth are

engaged in the workpiece at any one time. (Too few teeth will

cause teeth to strip out.)

• Never use a blade finer than required to obtain a satisfactory

surface finish or satisfactory flatness. (Too many teeth engaged in

the workpiece will prevent attainment of a satisfactory sawing rate;

frequently causes premature blade wear; frequently produces

“dished” cuts or cuts which are neither square nor parallel.)

• The chart which follows is not expected to be exactly correct for

all cases. It is intended as a general guide to good sawing

practice. Your blade supplier or factory application engineer

should be your most reliable source of correct information for

operational details of saw blades and their use.

NOTE:

• When standard wall pipe or tubing or thin wall tubing, channel

iron, angles I-beams are cut, a 10 pitch saw blade of “wave” set

type is frequently used to good advantage. Fewer than 10 teeth

per inch of saw will almost never be satisfactory.

• Tubing or structurals with wall thickness or web thickness of 1/2˝

or more can usually use an 8 or 6 pitch blade satisfactorily.

• When rectangular, solid bar is to be sawed, the work should,

whenever possible, be loaded with the thinnest cross section

exposed to the blade teeth. The pitch (or number of teeth per

inch of blade) selected must provide engagement of at least 3

consecutive teeth in the workpiece. Should application of this

rule not be possible because the thinnest cross section is too

thin, the piece must be loaded with the wider dimension

exposed to the saw teeth and a coarser blade selected from the

listing of recommendations for round and square solid bars.

BLADE TEETH PER INCH (TPI)

Choose a blade with the proper number of teeth per in (TPI) for the

material being cut. The following factors should be considered:

• Parts with a thin and/or variable section such as profiles, pipes

and plate, need closely space teeth, so that the number of teeth

used simultaneously in cutting ranges from 3 to 6.

• Parts with large crosscut sections and solid cores need widely

spaced teeth to allow for the greater volume of the shavings and

better tooth penetration.

• Parts made of soft material or plastic (light alloys, mild bronze,

Teflon, wood, etc. also require widely spaced teeth.

• Pieces cut in bundles require combo tooth design.

BLADE STRUCTURE

Bi-metal blades are the most commonly used. They consist of a

silicon-steel blade backer along with a laser welded high speed steel

(HSS) cutting edge. These type of blades are classified by a M2, M42,

M51 designation. They differ from each other because of their

hardness due to the percentage of Cobalt (Cc) and molybdenum

(Mo) contained in the metal alloy.

BLADE TYPE

Blades differ because of their construction characteristics, such as:

• Shape and cutting angle of tooth

• Pitch

• Set shape

• Angle (rake) of the teeth

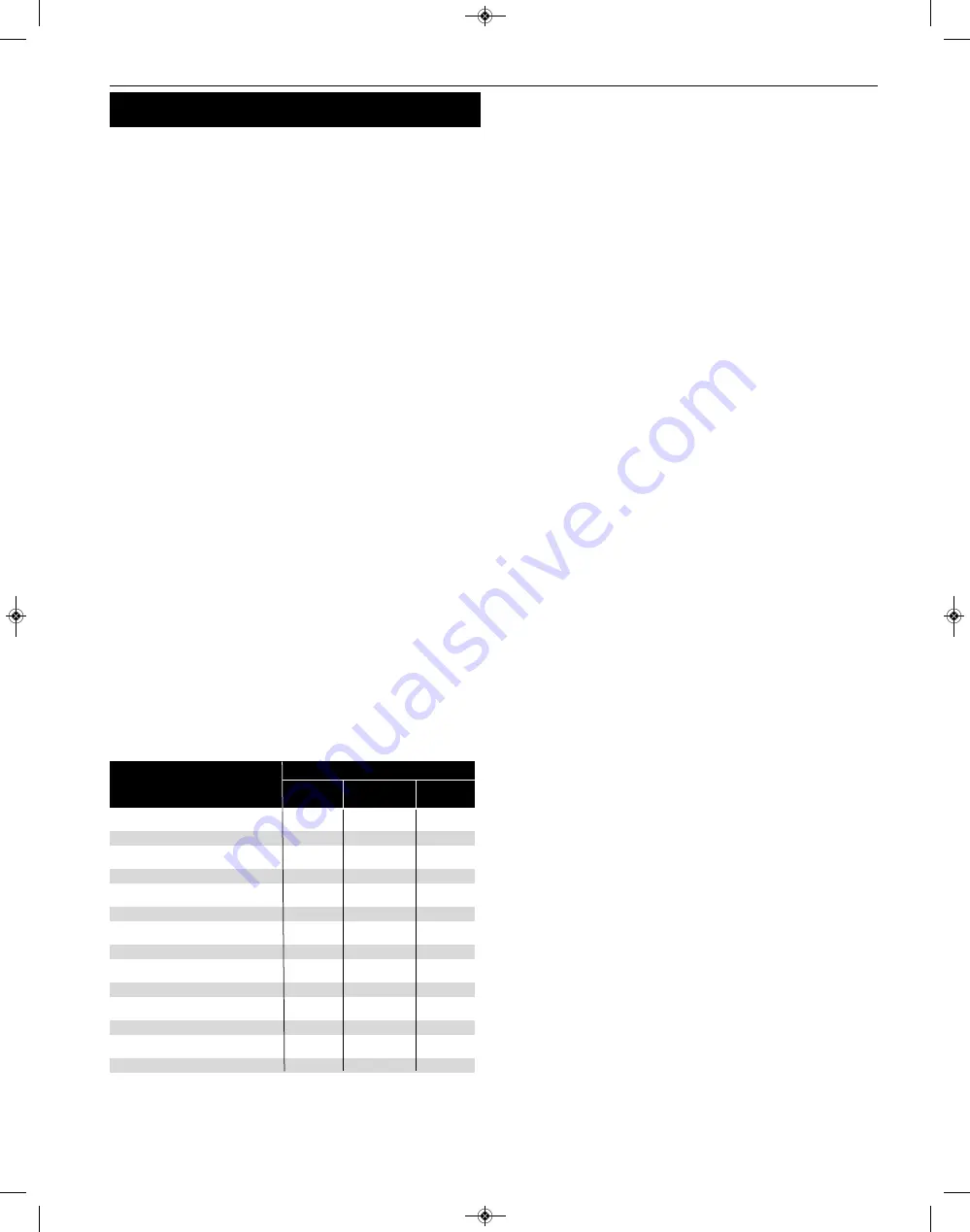

Probable Pitch/Teeth Per Inch

Workpiece Size

Second

Third

(Solid Bars)

Best

Best

Best

Less than 1˝ Dia. or Sq.

10

1˝ Dia. or 1˝ Sq.

8

10

6

1 ½˝ Dia. or 1 ½˝ Sq.

8

10

6

2˝ Dia. or 2˝ Sq.

8

6

4

2 ½˝ Dia. or 2 ½˝ Sq.

6

8

4

3˝ Dia. or 3˝ Sq.

6

4

3

3 ½˝ Dia. or 3 ½˝ Sq.

6

4

3

4˝ Dia. or 4˝ Sq.

4

3

6

4 ½˝ Dia. or 4 ½˝ Sq.

4

3

6

5˝ Dia. or 5˝ Sq.

4

3

6

6˝ Dia. or 6˝ Sq.

4

3

6

7˝ Dia. or 7˝ Sq.

4

3

6

8˝ Dia. or 8˝ Sq.

4

3

6

9˝ Dia. or 9˝ Sq.

4

3

6

9683295_oipm_En012_9645931.01-0620 __ 07-02-2020 . . . .