Page 42

TU2506

ǀ

TU2807V

US

INFORMATION

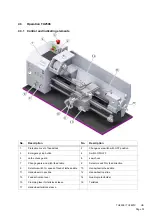

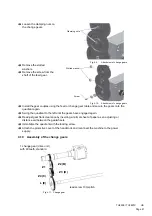

The assembly of the change wheels may be performed in the sequence that the standard gear

(1st drive unit) first cams into gear B, then gear B to gear D and gear C to gear E.

General

According to DIN 868, the gear transmission ratio is the ratio of the driving gears to the driven

gears.

Example

To calculate metric pitch (mm), multiply lead screw pitch (mm) by gear transmission ratio:

To calculate imperial pitch (tpi), divide lead screw pitch tpi (threads per inch) by gear transmis-

sion ratio:

The number 10 in the above calculation is the tpi pitch of the lead screw.

The number 40 is the number of the teeth on 1st drive unit.

Vg in the above calculation is gearbox transmission ratio:

- (Vg) position "A" transmission ratio = 1

- (Vg) position "B" transmission ratio = 0.5

- (Vg) position "C" transmission ratio = 2

Gear Z2 (B) acts as idler gear and does not have any effect on gear transmission ratio.

Pitch (mm) =

40 x C

D x E

x

25.4

10

x

x

Z1 x Z2 x Z4

Z2 x Z3 x Z5

Vg

Vg = 2.54

x

Pitch (tpi) = 10 :

x Vg

D x E

40 x C

Vg = 10 x

Z1 x Z2 x Z4

Z2 x Z3 x Z5

x Vg = 10 :

40 x B x C

B x D x E

x Vg = 10 :

x

40 x C

D x E

Summary of Contents for TU 2506

Page 1: ...US Item No 9684509 Operating manual Version 2 2 2 Lathe...

Page 74: ...Page 74 TU2506 US...

Page 92: ...Page 92 TU2506 TU2807V US 8 Wiring diagrams 8 1 TU2506 Fig 8 1 Wiring diagram TU2506...

Page 93: ...Page 93 TU2506 TU2807V US 8 2 TU2807V 230V Fig 8 2 Wiring diagram TU2807V...

Page 98: ...Page 98 TU2506 TU2807V US...