Page 47

TU2506

ǀ

TU2807V

US

4.15

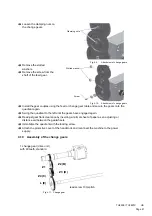

Replacing the clamping jaws on the lathe chuck

The clamping jaws and the three-jaw chuck

are provided with numbers. Check before

the change, if the numbers are readable

and, if necessary, mark the jaws and their

primary position. Insert the clamping jaws at

the correct position and in the right order into

the three-jaw chuck.

After the replacement, bring the jaws com-

pletely together in order to see if they are

inserted correctly.

Fig.4-17:

Three- jaw chuck / clamping jaws

1

2

3

3

2

1

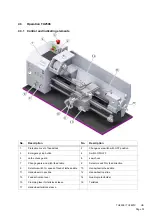

Summary of Contents for TU 2506

Page 1: ...US Item No 9684509 Operating manual Version 2 2 2 Lathe...

Page 74: ...Page 74 TU2506 US...

Page 92: ...Page 92 TU2506 TU2807V US 8 Wiring diagrams 8 1 TU2506 Fig 8 1 Wiring diagram TU2506...

Page 93: ...Page 93 TU2506 TU2807V US 8 2 TU2807V 230V Fig 8 2 Wiring diagram TU2807V...

Page 98: ...Page 98 TU2506 TU2807V US...