Page 53

TU2506

ǀ

TU2807V

US

5

Maintenance

In this chapter you will find important information about

Inspection

Maintenance

Repair

of the lathe.

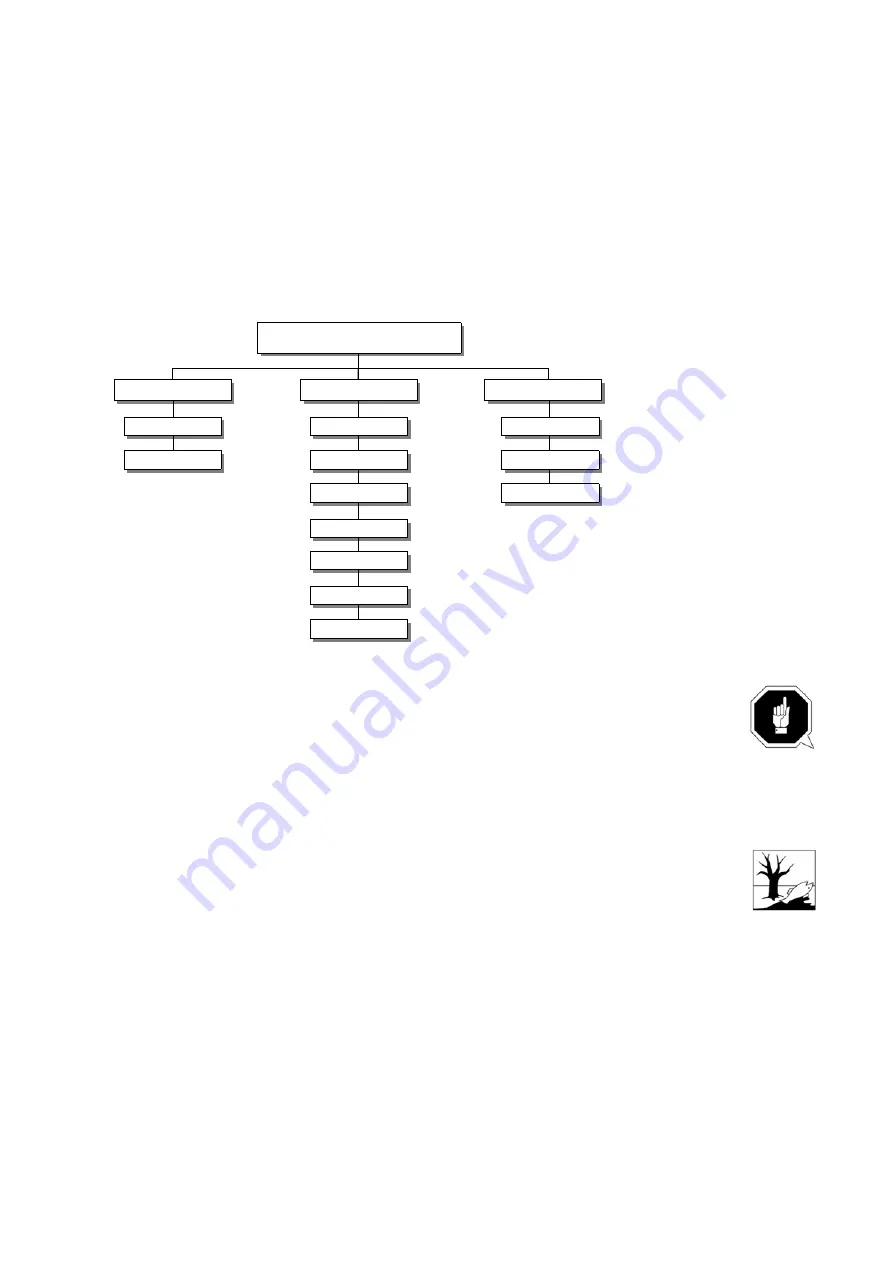

The diagram below shows which of these headings each task falls under.

Fig.5-1: Maintenance - Definition according to DIN 31051

ATTENTION!

Properly-performed regular maintenance is an essential prerequisite for

safe operation

fault-free operation

long service life of the lathe and

the quality of the products you manufacture.

Installations and equipment from other manufacturers must also be in

company

condition.

ENVIRONMENTAL PROTECTION

During work on the bit-holder head, make sure that

collector vessels are used, with sufficient capacity for the amount of liquid to be col-

lected.

liquids and oils are not spilt on the ground.

Clean up any spilt liquid or oils immediately using proper oil-absorption methods and dispose of

them in accordance with current legal requirements on the environment.

Cleaning up spillages

Do not re-introduce liquids spilt outside the system during repair or as a result of leakage from

the reserve tank: collect them in a collecting vessel to be disposed of.

Disposal

Never dump oil or other pollutant substances in water inlets, rivers or channels.

Used oils must be delivered to a collection centre. Consult your superior if you do not know

where the collection centre is.

MAINTENANCE

Inspection

Maintenance

Repairs

Measuring

Rough cleaning

Mending

Testing

Fine cleaning

Replacing

Conserving

Lubricating

Completing

Replacing

Readjusting

Adjusting

Summary of Contents for TU 2506

Page 1: ...US Item No 9684509 Operating manual Version 2 2 2 Lathe...

Page 74: ...Page 74 TU2506 US...

Page 92: ...Page 92 TU2506 TU2807V US 8 Wiring diagrams 8 1 TU2506 Fig 8 1 Wiring diagram TU2506...

Page 93: ...Page 93 TU2506 TU2807V US 8 2 TU2807V 230V Fig 8 2 Wiring diagram TU2807V...

Page 98: ...Page 98 TU2506 TU2807V US...