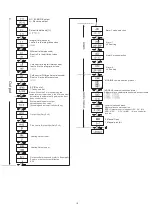

9. Access Parameter Menu

Schematic diagram of each level (how to switch

s)

level

*Return to level 0(operation setting level if

no pressing any key within 30sec

Operation set up

level

Press

Press

and

for 3sec

Press

Press

Press

Press

Press

Program parameter

setup level

and

and

and

and

and

Parameter control

setup level

Output calibration

parameter level

(

Manufacturer specialized)

Iutput calibration

parameter level

(

Manufacturer specialized)

Operation setup level

(general operation level

power ON

self-

diagnosis

self-diagnosis

(all lights turn on)

Input signal type display

Output percentage monitor

Only for MG904

、

MG907)

0:Stop

1:Run(when power off and then power on return to “0",

when running set”1")

2:Run(Not return to “0"when power off and then power on

,still as “2"

Auto Tuning

1:ON

2:None

Alarm 1 setting

Alarm 2 setting

Input signal range display

Lower limit

Upper limit

5s

5s

PV/SV value

refer to Example1

Cold controlled proportional band

Cold control output cycle(s)

Control

Program setup level

(Engineer operation level)

Data lock

LCK=0001,only allow changes SV,RUN

LCK=0010,allow level0 process mofication

set input type

please refer to “5.Input Type Table”

Input filtering constant

M

e

a

s

u

re

m

e

n

t V

a

lu

e

PV1,off Set

Constant Value

Consumption Value

1.TM1=0,TM2=0

TM=3 none compensation

2.When TM1=USP,TS1 is constant

consumption(whole measurement

range

(refer to Example 3)

PV1,off Set

PV1 lower limit

PV1 upper limit

decimal Set

Temperature unit

0:

℃

1

:℉

5

0.0-50.0