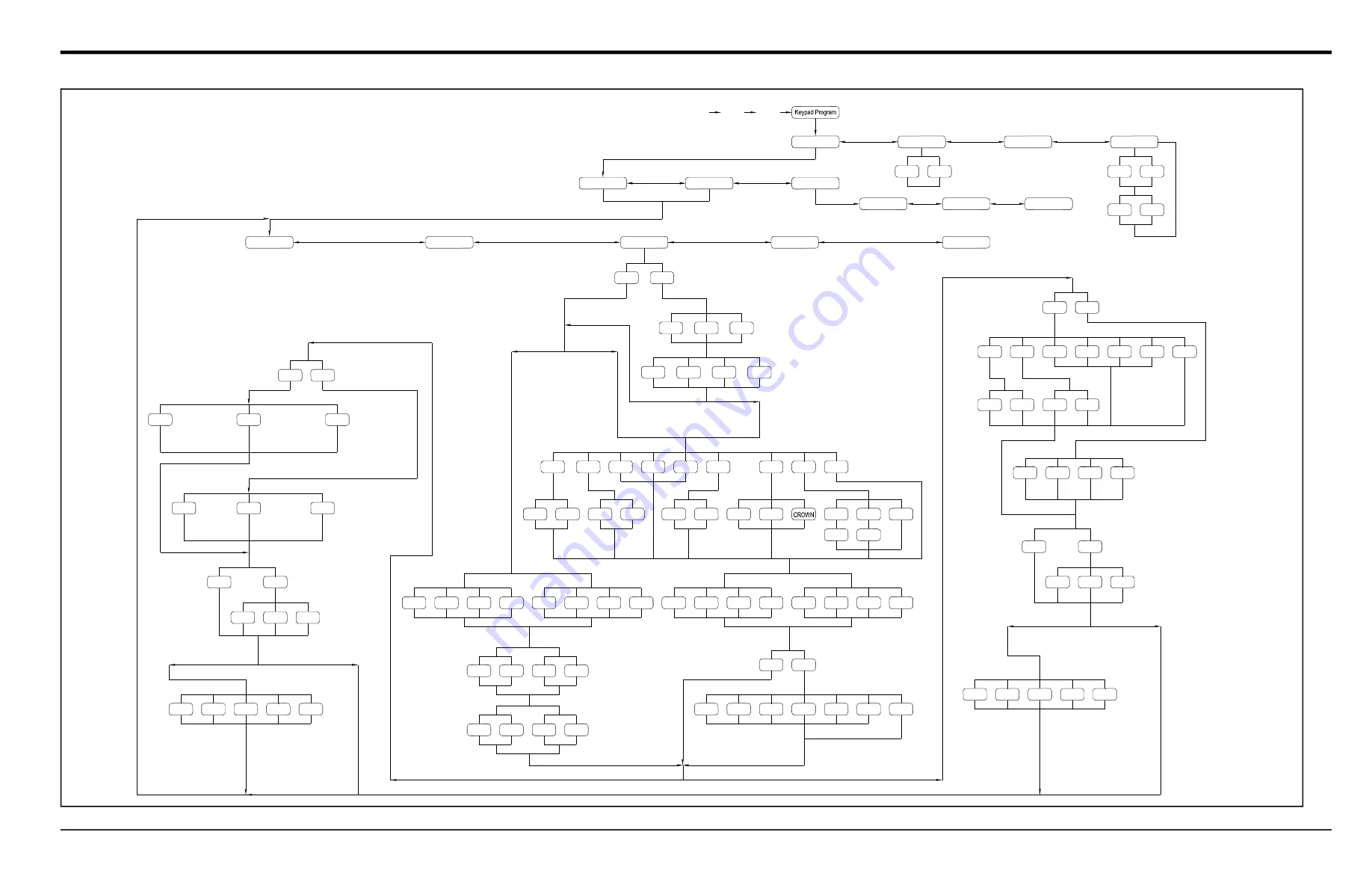

Appendix A. Menu Maps

DigitalFlow™ XMT868i Programming Manual

[Esc]

[Enter]

[Esc]

PROG

RESET

CALIB

CONTRAST

CH2*

GLOBL

CH1

(* for 2-Channel meter only)

I/O

COMM

SYSTM

PIPE

I/O

SETUP

SYSTM

ACTIV

RAYL

SHEAR

WETTD

STD

SPEC

Cu

Al

BRASS

CuNi

GLASS

PLSTC

OTHER

See Figure A-1

See Figure A-1

TRANSDUCER NUMBER

SPECIAL TRANSDUCER

WEDGE TYPE

1MHz

2MHz

5MHz

500k

FREQUENCY

(RAYL/SHEAR)

STEEL

IRON

WEDGE SOUNDSPEED

WEDGE ANGLE

PIPE MATERIAL

10%Ni

PYREX

FLINT

NYLON

POLYE

POLYP

CAST

30%Ni

DUCT

CARBN

SS

PVC

ACRYL

PIPE SOUNDSPEED

feet

cir.in

cir.ft

m

cir.mm

cir.m

inch

mm

PIPE OD

(Metric)

(English)

feet

cir.in

cir.ft

m

cir.mm

cir.m

inch

mm

PIPE OD

(Metric)

(English)

(WETTD)

(Clamp-on Type)

(Wetted Type)

feet

mm

m

inch

PIPE WALL

PATH LENGTH P

(English)

(Metric)

feet

mm

m

inch

AXIAL LENGTH L

(English)

(Metric)

PIPE WALL

LINING

YES

NO

TAR

PYREX

ASBES

RUBBR

TEFLN

OTHER

MORTR

LINING MATERIAL

LINING SOUNDSPEED

LINING THICKNESS

YES

NO

TRACKING WINDOWS?

WATER

MIXED

OTHER

WATER TEMPERATURE

FLUID SOUNDSPEED

FLUID SOUNDSPEED

Percentage of Water

W260

MIXED

OTHER

MINIMUM SOUNDSPEED

Percentage of Water

MAXIMUM SOUNDSPEED

OFF

ACTIVE

SOUND

STATC

SIGS

KV INPUT SELECTION

KINEMATIC VISCOSITY

REYNOLDS CORRECTION

CALIBRATION FACTOR

(Wetted Transducers)

(Clamp-On Transducers)

2(V)

3

4

1(Z)

5

NUMBER OF TRAVERSES

TRANSDUCER SPACING

Energy Option OFF

Energy Option ON

OIL

METH

ETH

FREON

OTHER

WATER

LN2

SEA

LUBE

CRUDE

NORML

W260

OIL

OTHER

W100

NO

YES

TRACKING WINDOWS?

MINIMUM SOUNDSPEED

MAXIMUM SOUNDSPEED

FLUID TYPE

WATER

FLUID SOUNDSPEED

OFF

ACTIVE

SIGS

SOUND

STATC

KV INPUT SELECTION

REYNOLDS CORRECTION

KINEMATIC VISCOSITY

CALIBRATION FACTOR

(Wetted Transducers)

(Clamp-On Transducers)

1(Z)

2(V)

4

5

3

NUMBER OF TRAVERSES

TRANSDUCER SPACING

TEMPERATURE

See Figure A-4

FLUID TYPE

FLUID TYPE

See Figure A-4

See Figure A-4

See Figure A-1

See Figure A-3

DARKN

LITEN

STORE

ABORT

WEDGE TEMPERATURE

FLUID TYPE

NO

YES

Fi

gu

re

2

9:

C

ha

nn

el

X

-

P

IP

E

M

en

u

M

ap

Summary of Contents for DigitalFlow XMT868i

Page 2: ......

Page 4: ...ii no content intended for this page...

Page 50: ...Chapter 1 Programming Site Data 42 DigitalFlow XMT868i Programming Manual...

Page 74: ...Chapter 4 Printing Data 2 DigitalFlow XMT868i Programming Manual...

Page 78: ...Chapter 5 Clearing Data 4 DigitalFlow XMT868i Programming Manual...

Page 79: ...DigitalFlow XMT868i Programming Manual 5 Appendix A Menu Maps Appendix A Menu Maps...

Page 80: ...Appendix A Menu Maps 6 DigitalFlow XMT868i Programming Manual...

Page 86: ...Appendix A Menu Maps DigitalFlow XMT868i Programming Manual...

Page 144: ...Appendix D PanaView Menu Maps for the XMT868i 70 DigitalFlow XMT868i Programming Manual...

Page 150: ...Appendix A PanaView Menu Maps DigitalFlow XMT868i Programming Manual 76...

Page 162: ...Warranty 6 AquaTrans AT868 User s Manual no content intended for this page...

Page 163: ......