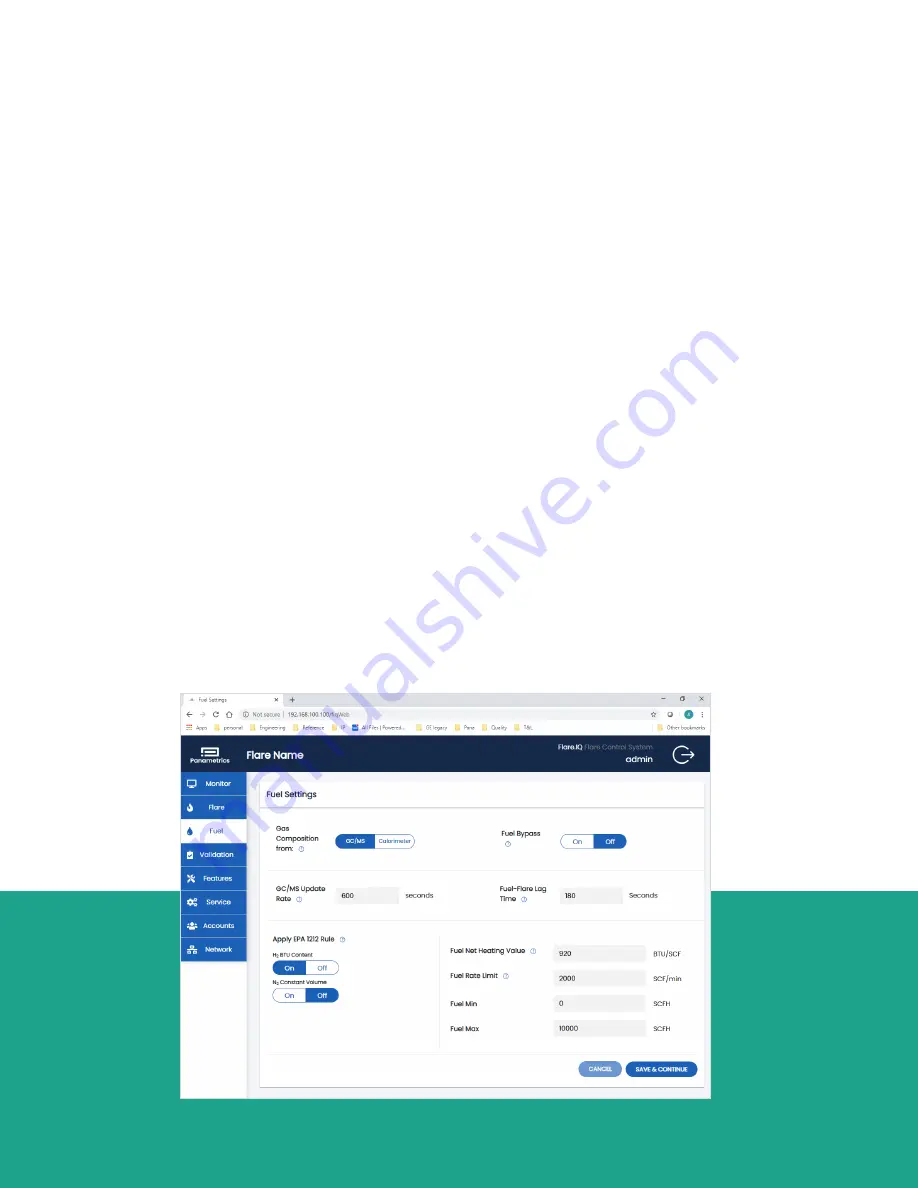

3.3.4 Fuel configuration

As shown in figure 21 this page enables setting the

following flare (supplemental) fuel specific parameters:

• Choice of online flare gas analyzer – GC/calorimeter

• Time interval between readings from GC/MS

• Minimum allowed fuel flow

• Maximum allowed fuel flow

• Lag time between fuel flow change and flare

meter response

• Action threshold for changes in steam or

fuel demand

• Nominal fuel net heating value (natural gas

in this example)

The bottom left of the fuel page has two special

configuration parameters:

1. Choice of NHV for H2 between 275 BTU/SCF and

1212 BTU/SCF (apply EPA 1212 rule)

2. Choice of constant N

2

volumetric flow (i.e., N

2

mole

fraction inversely proportional to total flare gas flow)

or constant N

2

mole fraction

In addition to tooltips, detailed information on the purpose

of each of the above settings as they apply to your flare

installation along with in-depth instructions on how to

determine the correct values to enter can be obtained

from your Panametrics field service engineer.

3.3.5 Monitor overview

After all configuration steps are complete, the monitor

overview is displayed. This screen provides a real-time

readout of essential data being sent to the flare.IQ, and

the results the flare.IQ has calculated. Displayed data is

organized in ‘panes’ as follows:

• The heading bar displays the configured flare name

or tag, the Modbus connection status, and the user

currently logged in. A running time display indicates

updates of the data below.

• The system readouts pane shows the net heating

value (NHV) actual. This is the calculated energy

content at the flare tip, as determined by the gas

composition and energy content derived from the

vent/flare gas flowmeter measurements. NHV

actual

must remain above a critical value of 270 BTU/SCF

for EPA compliance under the MACT rules.

• This pane also shows the fuel demand and

steam or air demand. These are the quantities of

supplemental fuel and assist flow calculated by

the flare.IQ for optimal operation. It is these values

that the controlling DCS should use as setpoints

for the fuel flow, steam flow, or air flow.

• The flare pane displays the critical flare measurements

as captured by the DCS and sent to the flare.IQ. Use this

to verify that the data obtained from the flare flowmeter,

temperature, and pressure sensors is being reliably

transferred from the DCS to the flare.IQ.

Figure 21: Fuel settings configuration page

23

Summary of Contents for flare.IQ Generation 2

Page 1: ...flare IQ Generation 2 Operation and maintenance manual...

Page 2: ...2...

Page 3: ...flare IQ Generation 2 Operation and maintenance manual 910 350 rev A June 2020 3...

Page 4: ...no content intended for this page 4...

Page 38: ...Figure 30 System wiring diagram 38...

Page 48: ...48...