Chapter 5. Using PanaView

96

Sentinel LNG User’s Manual

5.7.2 Fluid Setup (cont.)

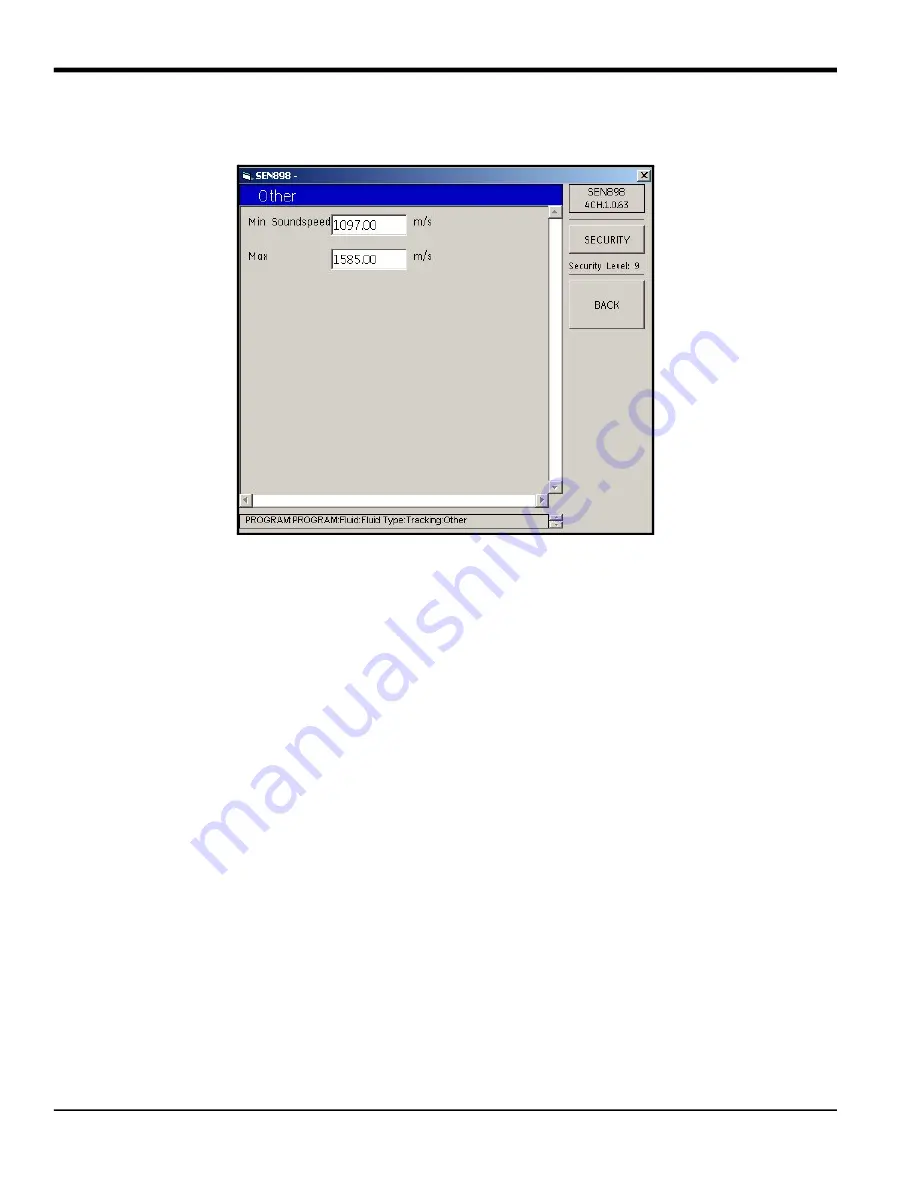

10.

If the fluid type is not standard, on the

Tracking

screen, click twice on

Other

and the following screen appears.

Figure 90: Other Fluid Menu

11.

Enter the fluid

Minimum

and/or

Maximum Soundspeed

, click on

BACK

, and click Yes to verify, or No to reject the change.

When the

Fluid

changes are complete, click on

BACK

to return to the composite

Program

menu.

Summary of Contents for Sentinel LNG

Page 2: ......

Page 4: ...ii no content intended for this page...

Page 6: ...Preface iv Sentinel LNG User s Manual...

Page 12: ...Contents x Sentinel LNG User s Manual...

Page 26: ...Chapter 1 Features and Capabilities Sentinel LNG User s Manual 14...

Page 178: ...Chapter 5 Using PanaView 166 Sentinel LNG User s Manual...

Page 184: ...Chapter 6 MODBUS Communications 172 Sentinel LNG User s Manual...

Page 202: ...Chapter 7 HART Communications 190 Sentinel LNG User s Manual...

Page 220: ...Chapter 9 Troubleshooting 208 Sentinel LNG User s Manual...

Page 222: ...Appendix A Menu Maps 210 Sentinel LNG User s Manual...

Page 230: ...Appendix A Menu Maps Sentinel LNG User s Manual 218...

Page 232: ...Appendix B CE Mark Compliance and High Noise Areas 220 Sentinel LNG User s Manual...

Page 236: ...Appendix C Data Records 224 Sentinel LNG User s Manual...

Page 240: ...Appendix C Service Record 228 Sentinel LNG User s Manual...

Page 244: ...Index 232 Sentinel LNG User s Manual...

Page 246: ...Warranty 234 Sentinel LNG User s Manual no content intended for this page...

Page 247: ......