Operation manual for Narrow-pitch connectors A35UH

Panasonic Corporation

industrial.panasonic.com/ac/e/

©

Panasonic Corporation 2017

ACCTF32E 201704

- 14 -

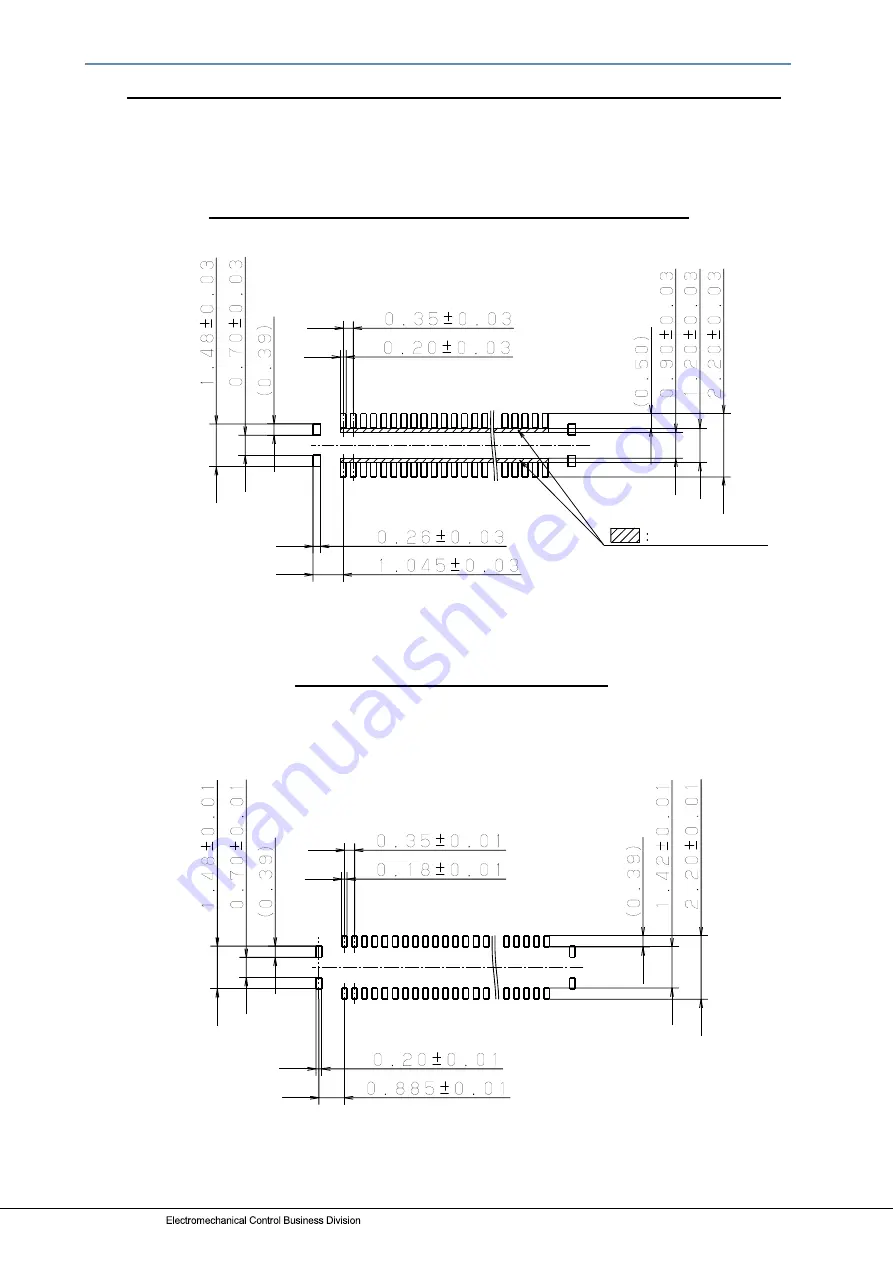

Recommended specifications for PC-board and metal mask opening area

Applicable product:A35US narrow-pitch connector header

(

Mated height

:

0.6mm

)

Recommended PC-board pattern (Mount-pad layout)

Recommended metal mask pattern

When the metal mask thickness is 100

µ

m

(Terminal section opening area: 70%)

(Metal section opening area: 77%)

Insulation area

Summary of Contents for A35UH

Page 30: ...ACCTF32E 201704 2017 ...