INF-4

2. MAINTENANCE

Maintenance is done by periodically performing suitable maintenance servicing in order to maintain the best

condition, so that the user can use the equipment safely. Video equipment with mounted mechanisms have parts

which will wear, and their wear and deterioration cause troubles. Dust and dirt also can impair stable operation. For

this reason it is important not to just perform repair at the time of trouble, but also to perform suitable maintenance

at regular intervals.

The maintenance schedule requires replacement of mechanism unit, which contains a cylinder unit and so on.

2-1. Maintenance Schedule

No.

Part Name

Part No.

Cleaning

Replacement

Remark

--- Tape

Transport

Part

------ 100

hours ------

*1

1

Mechanism Chassis Unit

VXY1903Z1

------

Every 2000 hours

*2

2

Zoom Motor Unit

L6DABBHC0001

------

Every 4000 hours

*2

Note:

Hours of use are based on the head rotation hours.

(Head rotation hours can be confirm on item HOUR METER in

OTHER FUNCTION menu.)

Hours of use are recommendation. It may depend on temperature, humidity, quality of tape or dust condition.

Hours of use are listed as the reference of maintenance. They do not mean guarantee hours.

*1. Tape Transport part is cleaned by cleaning liquid.

*2. Please refer to the most recent execution outline, as the maintenance specifications and the part numbers may

change.

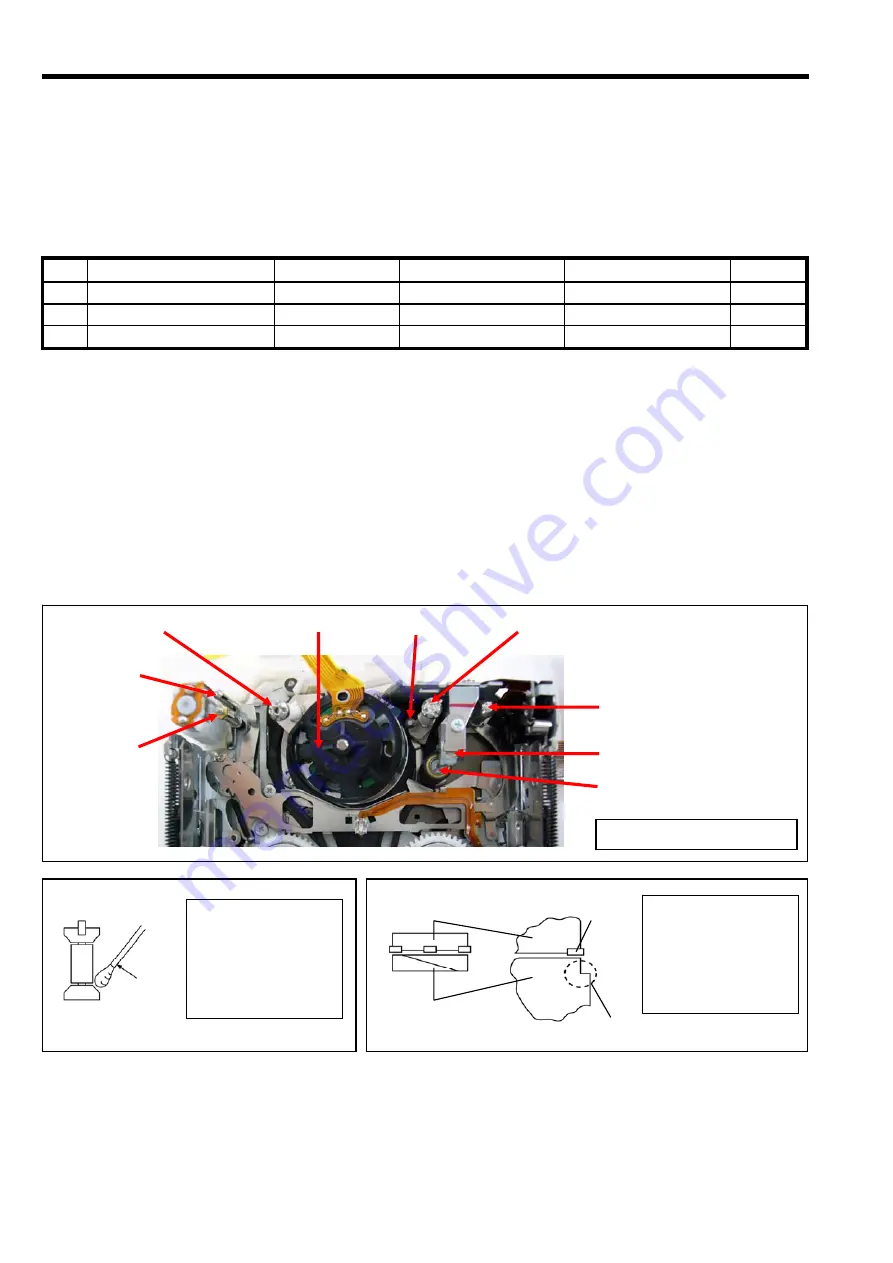

2-2. Cleaning of Tape Transport Part

Please clean the below indicated tape transport parts with cleaning liquid when needed.

(Tension Post, S1 Post, Cylinder & Heads, T1 Post, T2 Post, T3 Post, Capstan Shaft and Pinch Roller)

T2 Post

T1 Post

T3 Post

Capstan Shaft

Pinch Roller

S1 Post

Tension Post

S2 Post

Cylinder

LOADING condition

When cleaning the

post, wrap a cloth on a

pick. Wipe each post

with a cloth dipped in

cleaning liquid. And

wipe it again with dry

cloth.

Thin

stick

Upper Cylinder

Head

Lead

Do not forget cleaning

the upper Cylinder,

Head, tape transport

part of Lower Cylinder

and Lead, when

cleaning the Cylinder.

Lower Cylinder

Summary of Contents for AGDVX100BP - DVC CAMCORDER

Page 3: ...3...

Page 4: ...4 AG DVX100BE...

Page 5: ...5...

Page 7: ...7 AG DVX100BP...

Page 8: ...8 AG DVX100BE...

Page 9: ...9...

Page 10: ...10...

Page 11: ...MHNK150 0123457F6S8P...

Page 154: ...E14 1 2 3 9 4 5 6 7 8 102 102 101 101 MPL 7 LCD PARTS ASSEMBLY...