Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

Technical Terminology & Cautions for Use (Operation Switches)

Panasonic Corporation 2021

AECTB38E 202110

CAUTIONS FOR USE

Environment of use

1) Please consult us when using under the following conditions:

• Environments where hydrogen sulfide or other corrosive gases are

present.

• Environments where gasoline, thinner or other flammable,

explosive gases are present.

• Dusty environments (for non-seal type snap action switches).

• Use in environments not in the prescribed temperature or humidity

range.

• Places with low air pressure.

2) Unless specified the product will not be constructed to withstand

water, oil or explosions. Please inquire if you intend to use the

product in special applications.

Usage, storage, and transport conditions

1) During usage, storage, or transportation, avoid locations subject to

direct sunlight and maintain normal temperature, humidity, and

pressure conditions.

2) The allowable specifications for environments suitable for usage,

storage, and transportation are given below.

(1) Temperature: The allowable temperature range differs for each

switch, so refer to the switch’s individual specifications.

(2) Humidity: 5 to 85% R.H.

(3) Pressure: 86 to 106 kPa

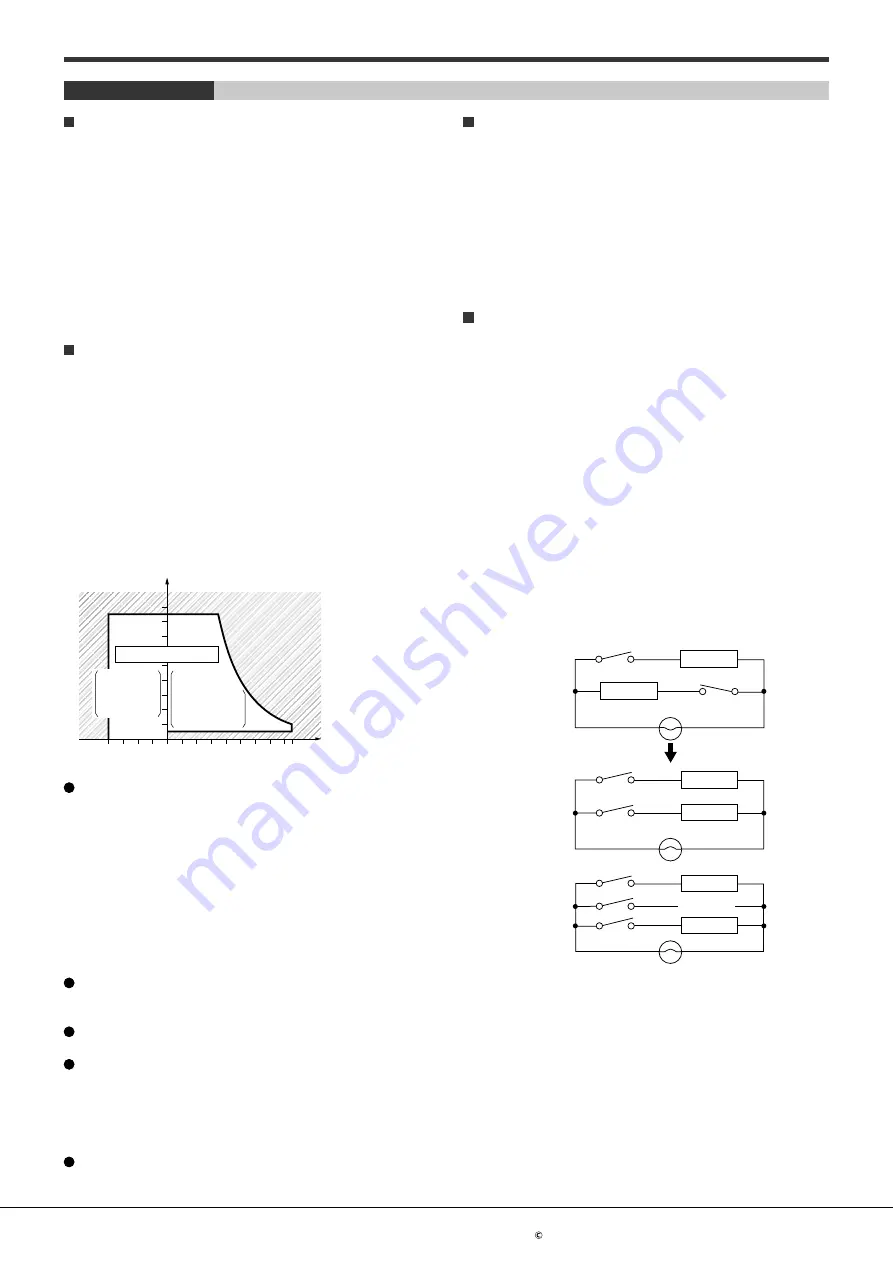

The humidity range varies with the temperature. Use within the

range indicated in the graph below.

(The allowable temperature depends on the switch.)

5

85

Humidity (% RH)

Avoid icing

when used at

temperatures

lower than 0°C

Avoid con-

densation when

used at tem-

peratures higher

than 0°C

Allowable range

Ambient temperature (℃)

0

85

-40

Condensation will occur inside the switch if there is a sudden

change in ambient temperature when used in an atmosphere of

high temperature and high humidity. This is particularly likely to

happen when being transported by ship, so please be careful of

the atmosphere when shipping. Condensation is the phenomenon

whereby steam condenses to cause water droplets that adhere to

the switch when an atmosphere of high temperature and humidity

rapidly changes from a high to low temperature or when the

switch is quickly moved from a low humidity location to one of high

temperature and humidity.

Please be careful because condensation can cause adverse

conditions such as deterioration of insulation, coil cutoff, and rust.

Condensation or other moisture may freeze on the switch when

the temperatures is lower than 0°C. This causes problems such as

sticking of movable parts or operational time lags.

The plastic becomes brittle if the switch is exposed to a low

temperature, low humidity environment for long periods of time.

Storage for extended periods of time (including transportation

periods) at high temperatures or high humidity levels or in

atmospheres with organic gases or sulfide gases may cause a

sulfide film or oxide film to form on the surfaces of the contacts and/

or it may interfere with the functions. Check out the atmosphere in

which the units are to be stored and transported.

In terms of the packing format used, make every effort to keep the

effects of moisture, organic gases and sulfide gases to the

absolute

minimum.

Wiring

1) When using a P/C board terminal switch as soldering terminals, use

thin lead wires and be sure to wind them on the terminals before

soldering.

2) Cautions when soldering

Perform soldering quickly in accordance with the specified

conditions. Be careful not to let flux flow into the product. When no

instruction is specified, use a soldering iron with a tip temperature of

350 C or lower and complete soldering within five seconds. Do not

pull on the lead wires immediately after soldering. Wait some time

before verifying.

Others

1) Failure modes of switches include short-circuiting, opencircuiting

and temperature rises. If this switch is to be used in equipment

where safety is a prime consideration, examine the possible effects

of these failures on the equipment concerned, and ensure safety by

providing protection circuits or protection devices. In terms of the

systems involved, make provision for redundancy in the design and

take steps to achieve safety design.

2) The ambient operating temperature (and humidity) range quoted is

the range in which the switch can be operated on a continuous

basis: it does not mean that using the switch within the rating

guarantees the durability performance and environment

withstanding performance of the switch. For details on the

performance guarantee, check the specifications of each product

concerned.

3) Even if 2-pole, 3-pole or 4-pole switches are used as singlepole

switches in order to increase contact reliability, please keep the

maximum current no higher than the rated value.

4) If there is the possibility of a short between poles, please use an

in-phase circuit as shown below or provide a spare pole.

Load 1

Load 1

Load 1

Load 2

Load 2

Load 2

Bad example

Good example①

Good example②

Heteropolar circuit

In-phase circuit

Spare pole

5) Be careful not to drop the product as this may cause loss of

functionality.

6) Do not apply an unreasonable vertical force against the direction of

operation of the product.

7) Use your hand to operate the actuator.

(Operation using a tool such as a screwdriver or hammer can cause

breakdown.)

ー 10 ー