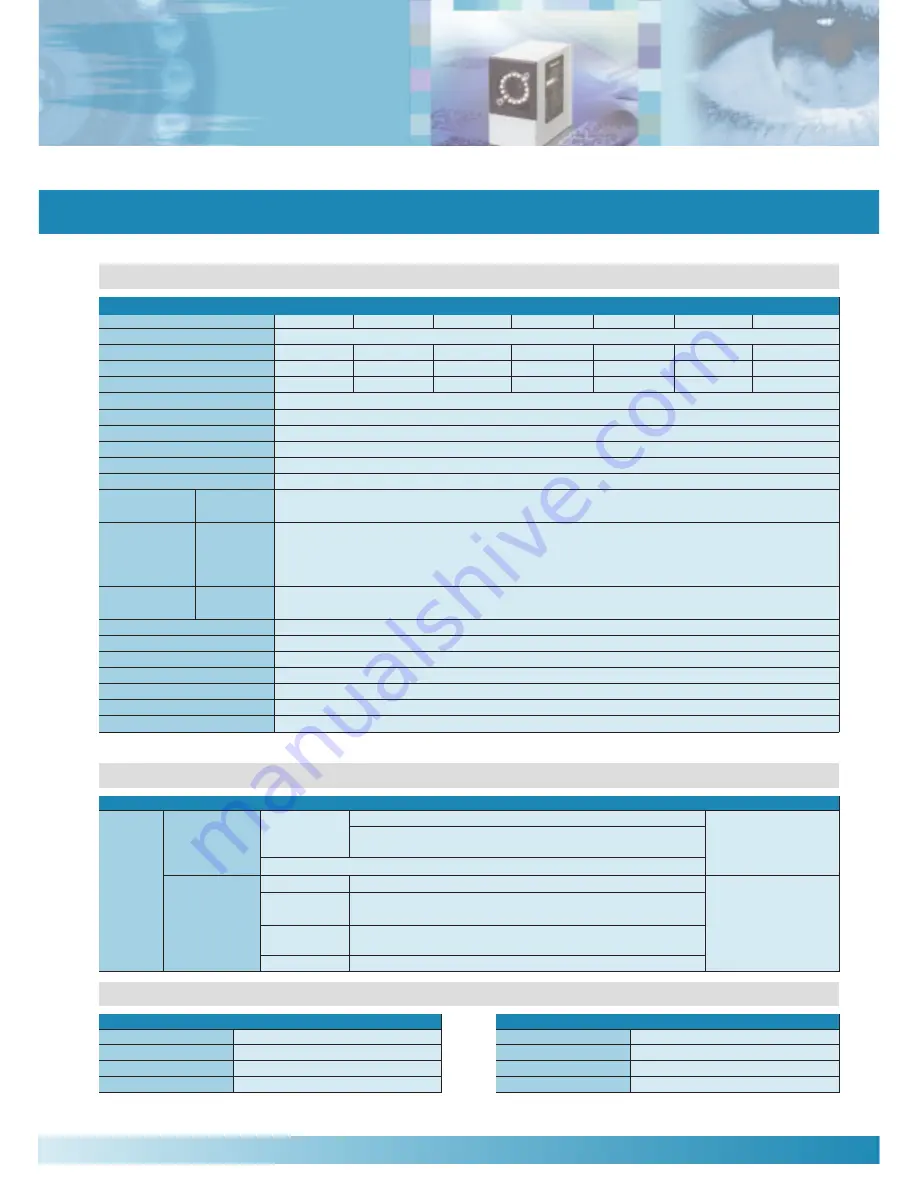

Item

Specification

Order Number

ANPD050-02

ANPD050-05

ANPD050-10

ANPD050-15

ANPD050-20 ANPD050-25

ANPD050-30

Configuration

Via software free of charge software PDTOOL or optional Operation/Finder unit

Field of view W x H (mm)

2 x 1.6

5 x 4

10 x 8

15 x 12

20 x 16

25 x 20

30 x 25

Minimum Cell Size (µm)

28 x 28

71 x 71

139 x 139

213 x 213

284 x 284

355 x 355

434 x 434

Installation distance (mm)

15 ± 0.5

25 ± 1.5

45 ± 2.5

60 ± 3.0

80 ± 4.0

105 ± 5.5

55 ± .0

Sensing element

Colour-CMOS with 330.000 pixels

Resolution

352 x 288 pixels

Detection capability

Min. 5 pixels per cell

Integrated light

White LED, light amount half-life: min. 30.000 h (at 25°C)

Exposure time

0.03 to 50 ms

Visual pilot beam

Red LED

RS232C (when using optional cable)

1.200 – 57.6000 bit/s, 8 bit ASCII, full duplex

5 Opto-coupler inputs, max. 30 VDC

(trigger, teach, 3 x type change)

5 PhotoMOS outputs, 5-24 VDC

(ready, alarm, 3 x data)

USB 1.1 for communication with PC (98SE, ME, 2000, XP)

LVDS for communication with Operation/Finder Unit

Processing time

30 ms

Operation voltage

24 VDC ± 10%

Current consumption

≤

0.5 A

Ambient temperature use/storage

0 to +40°C / -20 to +60°C

Ambient humidity

Usage and storage: 35 to 85% RH (@ 25°C no freezing or condensation)

Housing

IP67

1)

, aluminium

Weight

Approx. 400 g (Main Unit)

Digital I/O

Others

Serial

Interfaces

≤

Item

Specification

Readable

Square codes: 10 x 10 cells to 44 x 44 cells

code type

Rectangular codes: 8 x 18 cells, 8 x 32 cells, 12 x 26 cells,

12 x 36 cells, 16 x 36 cells, 16 x 48 cells

Supports black/white reversed codes, horizontally-flipped codes, and dots.

Model

Model 1 and Model 2

Model 1: 21 x 21 cells to 49 x 49 cells (Ver. 1 to 8)

Model 2: 21 x 21 cells to 49 x 49 cells (Ver. 1 to 8)

Supports black/white reversed codes, horizontally-flipped codes, and dots.

Technical Specifications

Main Units

2D Code Reading

9

Data matrix

ECC200

Matrix Size

The matrix size is

automatically

identified.

The model,

matrix size, and

the error correction level

are automatically

identified.

QR code

Matrix Size

Error

correction level

L (7%), M (15%), Q (25%), H (30%)

Operation Unit

Finder Unit

ANE12

Display

2-inch colour LCD

Backlight life

40,000 (at 25°C)

∆

Housing material

Plastic

Weight

Approx. 200g

ANE11

Display

7-segment, 3 colours

Setting function

Mode, SET, Parameter, Type, Trigger, UP/DOWN

Housing material

Plastic

Weight

Approx. 200g

1)

Expect when USB cable is connected

054731_Panasonic_3164euen-PD50 02.11.2005 14:00 Uhr Seite 9