- 12 -

Initial Center Static Convergence

Connect a dot/cross hatch generator to the Receiver

and tune in a signal. Observe misconvergence at

center of the screen only.

Adjust the R&B pole magnets; by separating tabs and

rotating to converge blue with red.

Adjust the R&B and R&B&G pole magnets: by

separating tabs and rotating to converge blue and red

(magenta) with green.

Note: Precise convergence at this point is

not important.

Purity Adjustment

When the Receiver is in the Service Mode for making

electronic adjustments, press the Recall button on the

Remote Control to enter Purity Check. (See the

Service Adjustments Electronic Controls

procedure).

Operate the Receiver for 60 minutes using the first

Purity Check field (white screen) to stabilize the CRT.

Fully degauss the Receiver by using an external

degaussing coil.

Press the Recall button on the Remote Control again

until the Purity Check (green screen) appears.

For a 2-piece assembly (see Fig. 5):

Loosen the deflection yoke clamp screw and move the

deflection yoke back as close to the purity magnet

as possible.

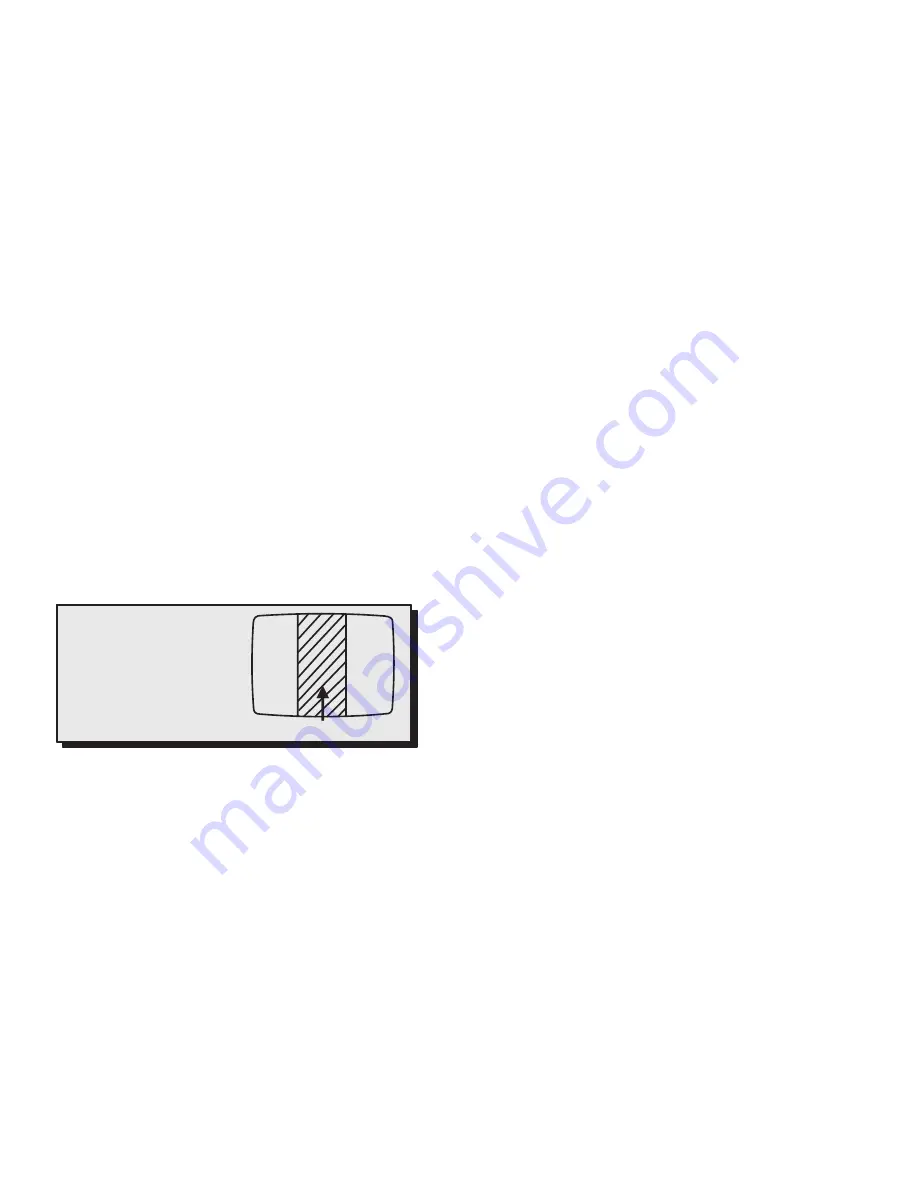

Adjust the Purity rings to set the vertical green raster

precisely at the center of the screen (see Fig. 10).

Slowly move the deflection yoke forward until the best

overall green screen is displayed.

For a 1-piece assembly (see Fig. 8):

Slowly move the deflection yoke and purity rings

assembly toward the CRT board and adjust the purity

magnet rings to set vertical green raster at center of

screen (see Fig. 10).

Gradually move the deflection yoke & purity rings

forward and adjust for best overall green screen.

Continue from here for either assemblies:

Tighten the deflection yoke clamp screw.

Press the Recall button on the Remote Control again

until the purity check (blue screen) and (red screen)

appear and observe that good purity is obtained on

each respective field.

Press the Recall button on the Remote Control again

until Purity check (white screen) appears. Observe the

screen for uniform white. If purity has not been

achieved, repeat the above procedure.

Final Convergence Procedure

(see Fig. 11

through Fig. 13):

Note: Vertical size and focus adjustments must be

completed prior to performing the convergence

adjustment. Connect a dot pattern generator to the

Receiver. The Brightness level should not be higher

than necessary to obtain a clear pattern.

Converge the red and the blue dots at the center of the

screen by rotating the R&B pole Static Convergence

Magnets.

Align The converged red/blue dots with the green dots

at the center of the screen by rotating the R&B&G pole

Static Convergence Magnets. Melt wax with soldering

iron to reseal the magnets.

Slightly tilt vertically and horizontally (do not rotate) the

deflection yoke to obtain a good overall convergence.

If convergence is not reached at the edges, insert

permalloy (see following section) from the DY corners

to achieve proper convergence. Recheck for purity and

readjust if necessary.

After vertical adjustment of the yoke, insert wedge at 11

o’clock position, then make the horizontal

tilt adjustment.

Secure the deflection yoke by inserting two side

wedges at 3 and 7 o’clock positions.

Apply adhesive between tab (thin portion) of wedge

and CRT and place tape over the tab to secure to

the CRT.

Permalloy Convergence Corrector Strip (Part No. 0FMK014ZZ)

This strip is used in some sets to match the yoke and

CRT for optimum convergence. If the yoke or CRT is

replaced, the strip may not be required.

First converge the set without the strip and observe

the corners.

If correction is needed:

1.

Place strip between CRT and yoke, in quadrant

needing correction. Slowly move it around for

desired results.

2.

Press adhesive tightly to the CRT and secure

with tape.

NOTES:

1. CRT warm up with white screen

(three guns activated) is needed

to stabilize the shadow mask

expansion.

2. Initial center static convergence

(roughly centers three gun

beams) is required in order to

perform purity adjustment.

Figure 10. Green Raster Adjustment

Green Raster