Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

PhotoMOS

®

Cautions for Use

Panasonic Corporation 2022

ASCTB65E 202201

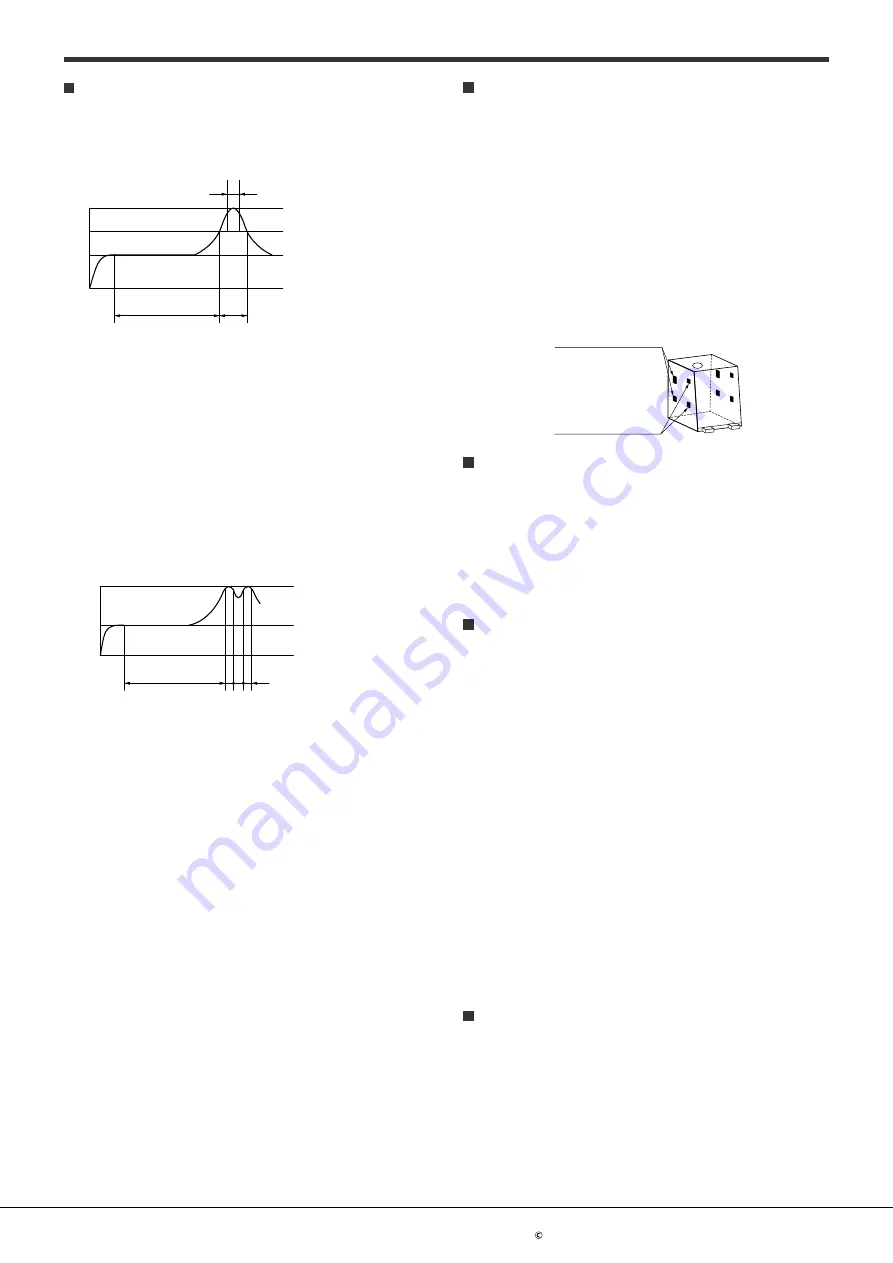

About the exposed terminals on the sides of the

package (for VSSOP)

For VSSOP type, as shown in the following figure, part of the input

and output frames are exposed on the sides of the package. Due to

this, please be keep in mind the cautions listed below.

1) Take care to avoid short circuits between exposed terminals,

which may cause insulation deterioration between input and

output, leading to destruction of internal elements.

2) Since the exposed terminals are connected electrically to the

internal element, please refer to the item “

■

Deterioration and

destruction caused by discharge of static electricity”, and

implement sufficient measures to control static electricity.

3) When installing the devices in the vicinity, please keep in mind

that if the exposed frames of adjacent devices get too close, a

short between devices may occur.

Part of frame on output side

Part of frame on input side

Adjacent mounting

When several PhotoMOS

®

are mounted closely each other or

heat-generating components are mounted close to the PhotoMOS

®

,

the abnormal heating may occur. This abnormal heat may be

caused by the internal element when energized or thermal

interference between the devices. The degree of temperature rise

depends on the mounting layout of the devices and usage condition,

therefore please be sure to use PhotoMOS

®

with reduced load

current after testing under the worst condition of the actual usage.

Transportation and storage

1) Extreme vibration during transport may deform the lead or

damage the PhotoMOS

®

characteristics. Please handle the outer

and inner boxes with care.

2) Inadequate storage condition may degrade soldering,

appearance, and characteristics. The following storage conditions

are recommended:

• Temperature: 0 to 45°C

• Humidity: Max. 70%RH

• Atmosphere: No harmful gasses such as sulfurous acid gas,

minimal dust.

3) Storage before TSON, VSSOP, SON, SSOP, or SOP processing

In case the heat stress of soldering is applied to the PhotoMOS

®

which absorbs moisture inside of its package, the evaporation of

the moisture increases the pressure inside the package and it

may cause the package blister or crack. This device is sensitive

to moisture and it is packed in the sealed moisture-proof package.

Please make sure the following condition after unsealing.

* Please use the device immediately after unsealing.

(Within 30 days at 0 to 30°C and Max. 70%RH)

* If the device will be kept for a long time after unsealing, please

store in the another moisture-proof package containing silica gel.

(Please use within 90 days.)

Water condensation

Water condensation occurs when the ambient temperature changes

suddenly from a high temperature to low temperature at high

humidity, or the device is suddenly transferred from a low ambient

temperature to a high temperature and humidity. Condensation

causes the failures such as insulation deterioration. Panasonic

Corporation does not guarantee the failures caused by water

condensation. The heat conduction by the equipment the

PhotoMOS

®

is mounted may accelerate the water condensation.

Please confirm that there is no condensation in the worst condition

of the actual usage. (Special attention should be paid when high

temperature heating parts are close to the PhotoMOS

®

.)

Soldering

1) Example of surface-mount terminal recommended conditions

(1) IR (Infrared reflow) soldering method

In case of automatic soldering, following conditions should be

observed. (recommended condition reflow: Max. 2 times,

measurement point: soldering lead)

t

3

T

3

T

2

T

1

t

2

t

1

T1 = 150 to 180°C

T2 = 230°C

T3 = 240 to 250°C*

t1 = 60 to 120 s

t2 = Within 30 s

t3 = Within 10 s

*240 to 245°C for SON, VSSOP

and TSON package

(2) Other soldering methods

Other soldering methods (VPS, hot-air, hot plate, laser

heating, pulse heater, etc.) affect the PhotoMOS

®

characteristics differently, please evaluate the device under

the actual usage.

(3) Manual soldering method

Temperature: 350 to 400°C, within 3s, electrical power 30 to

60W

2) Example of through hole terminal recommended conditions

(1) DWS soldering method

In case of automatic soldering, following conditions should be

observed. (recommended condition number of times: Max. 1

time, measurement point: soldering lead *1)

t

3

t

2

t

1

T

1

T

2

T

1

= 120°C

T

2

= Max. 260°C

t

1

= within 60 s

t

2

+t

3

= within 5 s

*1 Solder temperature: Max. 260°C

(2) Other soldering method (recommended condition: 1 time)

Preheating: Max. 120°C, within 120s, measurement point:

soldering lead

Soldering: Max. 260°C, within 10s, measurement area:

soldering temperature

(3) Manual soldering method

Temperature: 350 to 400°C, within 3s, electrical power 30 to

60W

ー 11 ー