Technical Terminology & Cautions for Use

AECTB36E 201811-T

MOUNTING STATE AND ENVIRONMENT

■

Checking the insulation distance

After mounting and wiring, check the insulation distance

between terminals and the ground. If the insulation distance is

inadequate, mount insulating material between as required.

■

Fastening the snap-action switch body

See the Section “CAUTIONS FOR USE” for the individual

switch.

■

Position adjustment with effector

1) The effector should be positioned so that direct force is not

applied to the plunger or actuator in its free position. The

operating force to the plunger should only be applied in a

perpendicular direction.

2) Note that the use of the switch as a stopper may cause an

operational problem.

■

Switch installation position

• Basically, the switch should be installed so that the object to

press the switch’s plunger or lever can press it down to 70 to

100% of OT of the switch. When determining the position, the

tolerance of OP (Operating Position) and other factors should be

taken into account.

The following describes the case where the strictest tolerance

conditions are adopted.

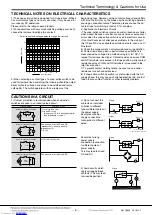

• Example: Hinge lever type FS switch

■

Soldering precautions

For manual soldering, lay the terminals flat (horizontal with the

ground) and quickly perform the soldering operation using a

soldering iron with the appropriate heat capacity and the proper

amount of solder. Take care that the flux does not flow into the

switch interior by using a ventilation fan to discharge flux gas

and to prevent contact of the switch body with the soldering iron

tip.

Be careful not to apply force to the lead wires or the terminal

portions immediately after soldering.

The temperature setting and time conditions vary depending on

the product.

See the section “CAUTIONS FOR USE” for each product.

■

Avoid using in a silicon atmosphere

Avoid using organic silicon rubber, adhesives, sealing

compounds, oil, grease, and wires in a silicon atmosphere.

■

Please consult us when using under the following

conditions*:

1) Environments where hydrogen sulfide or other corrosive

gases are present.

2) Environments where gasoline, thinner or other flammable,

explosive gases are present.

3) Dusty environments (for non-seal type snap action switches).

4) The perpendicular operating speed exceeds the allowable

operating speed.

5) Switching between different poles.

6) Use in environments not in the prescribed temperature or

humidity range.

■

Storage precautions

To prevent discoloration due to sulfurization of the terminals

(silver- plated), store the switches in a polyethylene bag or other

suitable airtight container.

(1) When the switch is not pressed

The object to press the lever should not be in contact with

the lever.

For this purpose, the object should be at a distance from

the switch father than the maximum FP (Free Position)

value.

FP max = OP max + PT max = 9.6 + 2.8 = 12.4 mm max

The object should be at a distance of 12.4 mm or more

from the mounting hole.

(2) Depressed position

The plunger/lever should be pressed down to 70% or

more of OT (Over Travel). Therefore, the depressed

position should be calculated based on the minimum

value of OP (Operating Position) and the 70 and 100% of

the OT value.

OP min - 70% of OT = 8.0 - 0.84 = 7.16 mm

OP min - 100% of OT = 8.0 - 1.2 = 6.80 mm

The plunger/lever should be pressed down to the position

of 6.80 to 7.16 mm from the mounting hole.

FP

OP

PT

TTP

OT

Reference values: OP = 8.8

±

0.8mm

PT = max. 2.8mm

OT = min. 1.2mm

<Examples>

Soldering iron tip

Wrong

Correct

ー 9 ー

Downloaded from

Downloaded from

Downloaded from

Downloaded from

Downloaded from

Downloaded from

Downloaded from

Downloaded from

Downloaded from