AECTB60E 202110

Panasonic Corporation 2021

FEATURES

Easy assembling as this switch is connector

integrated

High contact reliability by simple dust prevension

guard and Au-clad double layer contacts

Two types of contact form are available, the SPST-

NC and the SPST-NO.

The lever position can be changed. the standard

lever position and the backward lever position

Protection grade: IP40

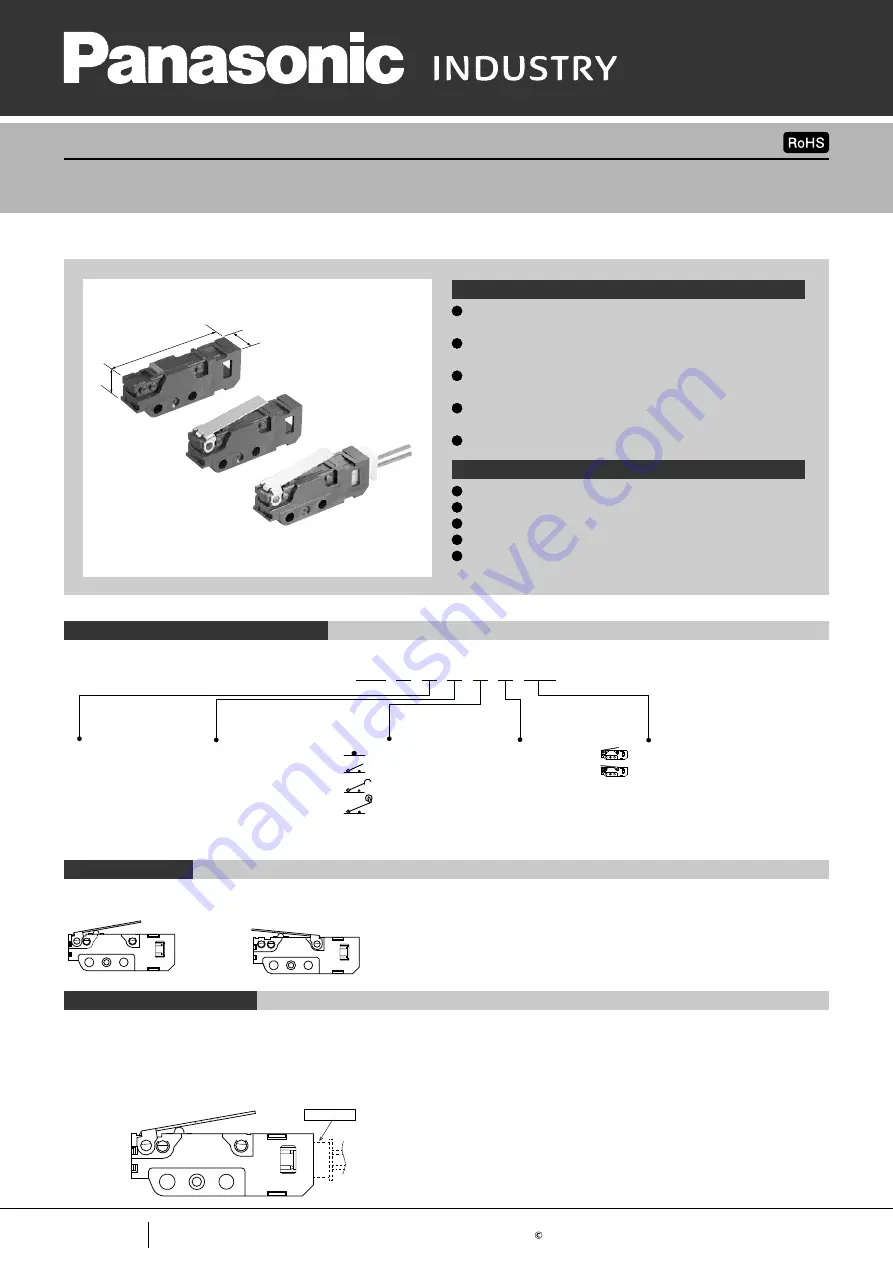

Subminiature Size Connector Integrated Type

AV6 (CS) Switches

For detection: Non Seal Type Switches

TYPICAL APPLICATIONS

Vending machine sold-out detection

Pachinko ball presence detection

Copying machine

Printer

Also for all types of equipment required for

maintenance and inspections.

(Unit: mm)

29.2

10

7

ORDERING INFORMATION (PART NO.)

AV 6

64

Operating Force (OP)

by pin plunger, Max.

2: 0.50 N

5: 1.50 N

Contact material

64: CuNi alloy+Au-clad contact

Contact form

2: SPST-NC

(Plunger color: Red)

3: SPST-NO

(Plunger color: Yellow)

Lever position

Nil: Standard

12: Backward

Actuators

0: Pin plunger

2: Hinge lever

4: Simulated roller lever

5: Roller lever

Note) When ordering, please add "-A" at the end of the part number.

LEVER POSITION

1) Standard

Connector

2) Backward

APPLICABLE CONNECTOR

Greatly improved assembling due to connector connection.

• Applicable connector: XA connector produced by JST Mfg. Co., Ltd.

Contact: SXA-001T-P0.6

Housing: XAP-02V-1

industrial.panasonic.com/ac/e/

2021.10

ー 1 ー